Everything is important in the construction of the building. However, the overlap in a wooden house at the same time - one of the most important elements. Taking the weight of everything that is on their surface in the house, they must perform many functions and meet the many serious requirements of construction and operation.

The stability of the whole house depends on the reliability and quality of the floors.

Next, some rules will be considered. It will be useful to find out the installation features of this structural element. Without this information, the overlap of a house made of wood will be incomplete.

Requirements for floors in a wooden house

Types of houses and types of floors in them.

In every house there are mandatory elements, without which its very existence is simply unthinkable. These elements include overlap. There are always several of them in the building, and they are structures that divide adjacent residential and non-residential rooms in height. Thus, the floors form floors, and also separate the rooms from the attic and basement. Interfloor overlappings, as a rule, are the basis for the floor.

Any overlap in a wooden house, regardless of its design and the materials from which it is made, provided that it is correctly installed, must meet a number of technological requirements. In view of the great importance of this structural element for the durability of the building and the safety of the people living or working in it, these requirements are quite severe. And ignoring them on the part of the builders can lead not only to the appearance of defects, but also to real accidents.

First of all, both self-weight and useful weight in the form of all kinds of equipment, room furniture, people in the house are putting pressure on the floor. Therefore, they must have a degree of strength sufficient to withstand all this total weight.

It should be noted that for rooms with different purposes, as well as depending on the properties of the equipment in them, this degree may be different. So, for the attic floor, the value of the payload that this structure can withstand cannot be more than 105 kg / m 2 , while, for example, for interfloor or basement floors, this indicator should not exceed 210 kg / m 2 .

The next important requirement is rigidity. This property is determined by the absence under the influence of loads noticeable (by eye or with the help of special devices) deflections in the overlap. The variation of this parameter from 1/200 of the span (for the attic) to 1/250 of the span (for the interfloor) is allowed.

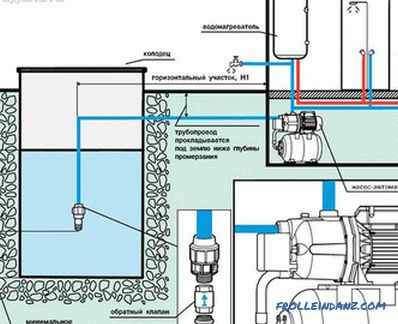

Foundation overlapping scheme.

Overlaps should have a sufficiently high degree of sound insulation. When installing these structural elements of wooden houses, appropriate technological and sanitary standards are used, which are enshrined in special recommendations and design documents.

No less important is the thermal insulation provided by the ceiling, especially when it comes to, for example, the ceiling between the first floor and the basement or the ceiling that separates the last floor from the attic.

The installation of ceilings and the requirements imposed on them are also affected by the material from which they were made. The relevant types of floors will be discussed in the next section.

Types of overlap depending on the load-bearing part

In accordance with the design decision, all the overlappings are divided into two large groups - beam and non-beam.

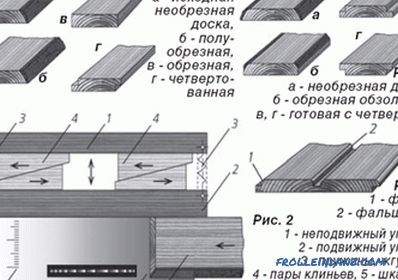

Types of wooden floors.

The first ones consist of the carrier part, which the beams are, and a special filling. The second ones are made of homogeneous structural elements - decking, made in the form of panels (slabs), or a solid monolithic slab, which serves as a simultaneously supporting and protective element.

Beamed floors of houses include structures made of wooden, metal and reinforced concrete beams. Note that the wooden beams today are very popular among private house builders. Such structures are used in the case of interfloor installation (span width - up to 5 m) and for the construction of floors for attics (span - up to 6 m). Experts consider this option one of the most high-quality, reliable and environmentally friendly.

Unlike rather massive wooden-beam structures, floorings based on metal beams seem to be no less reliable and more durable. At the same time, they compare favorably with wooden ones with a smaller thickness, which affects a substantial saving of the internal space of the rooms. However, this option is quite rare for wooden houses.

Sufficiently highly specialized - reinforced concrete beams. They are satisfied on spans, whose sizes vary from 3 m to 7.5 m. The weight of each such beam varies from 175-400 kg.In view of this, it is possible to install them in the house only with the use of a crane.

Types of attic floors.

Frameless structures, in turn, are divided into precast concrete, monolithic reinforced concrete and precast-monolithic. The first in a wooden house are used quite rarely, often in brick buildings.

Monolithic reinforced concrete floors are distinguished by a variety of forms. For the production of slabs with a thickness of 8 cm to 12 cm, concrete of grade 200 is used. But even more modern and advanced is the assembly of monolithic slabs. They are obtained by filling the space between the beams with hollow building blocks with upper concrete pouring.

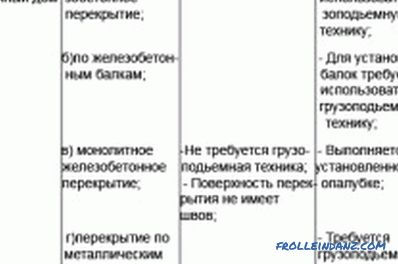

Advantages and disadvantages of beam and non-beam floors of houses

All the above-mentioned forms have their own structural advantages and disadvantages, which should be considered when choosing one or another option. You should get to know them better.

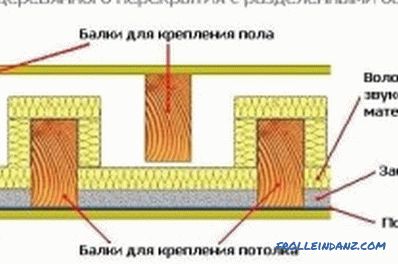

Wood floor plan with split beams.

The main advantage of the wooden joist is a fairly quick and easy installation in almost any place. Choosing this method, you can not worry about the organization of the crane and other construction equipment. For this reason, it costs the customer relatively inexpensively. At the same time (and this is a minus of this species), the tree is flammable, it can be spoiled by bark beetles, it lends itself to natural decay.

The advantages of metal beams are the possibility of using them to block large enough spans (up to 6 m or more) in the house, incombustibility and resistance to chemical and biological adverse effects. However, such beams can rust and quite actively conduct heat and various noises, which the customer is unlikely to like.

Reinforced concrete beams for the better differ from wooden ones by the possibility of using them to cover the spans larger than when using wooden beams. But at the same time, as noted above, their installation is inconceivable without special equipment.

Frameless ceilings also have their positive and negative sides. Thus, prefabricated reinforced concrete structures are very durable, they hold a load of 200 kg / m 2 and more. They are not afraid of the damaging effects of moisture and can do completely without maintenance. At the same time, their heavy weight makes it necessary to seek help from lifting mechanisms.

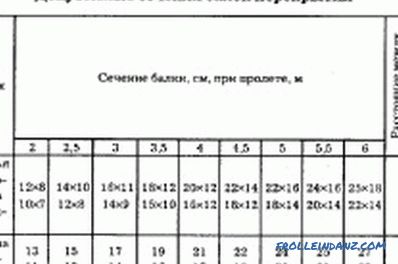

Table of allowable sections of floor beams for a certain span length.

Monolithic reinforced concrete floors are characterized by high surface quality of the slab. They are well suited for complex architectural planning. However, this option delivers a lot of trouble to the performers - for the manufacture of such overlap requires a special formwork, installed over the entire area of the floor under construction.

The method of prefabricated monolithic overlap differs in a number of technological advantages. In particular, the installation of such elements is quite easy, they demonstrate excellent thermal insulation qualities and fully satisfy the architects and engineers who develop the complicated forms of such overlap. At the same time, this process turns out to be unnecessarily time consuming, since it is necessary to do much manually.

Features of installation of overlappings of wooden houses

Structural elements dividing the space in the house into horizontal levels are mounted differently. And before planning this or that method, it is recommended to find out a number of features of the installation of each.

Schematic of the connection between the ceiling and the wall.

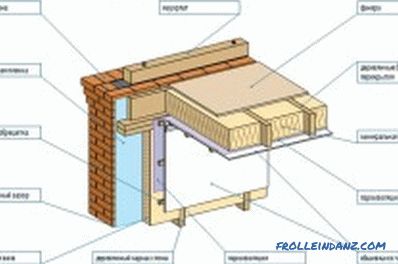

Installation of wooden beams, pre-treated with an antiseptic, is done with the help of peculiar beacons - mounting first of the extreme beams, along which the intermediate beams are then lined up. At the same time, the extreme beams should retreat from the wall of the building by about 5 cm. In this gap, the insulation is laid out.

For dense and reliable laying of beams in the wall, special niches are dredged. The ends of the beams are cut at an angle of 70-60 °, they are additionally impregnated with antiseptic and bipyrene. An additional fastening of the beam ends to the wall is also carried out by means of metal brackets or clamps. In addition, half of the beams is fixed with a metal anchor, which should go about 20 cm inside the future room.

Metal beams, made in the form of various rolled sections, should be installed in the house in such a way that hollowed reinforced concrete slabs with a thickness of at least 9 cm can be placed between them. layer - slag with a concrete screed.

Installation of reinforced concrete beams is carried out with a pitch of 600-1000 mm. The empty space between them is filled with slabs or hollow blocks of lightweight concrete, the joints between the beams and the elements of the aggregate are sealed with cement mortar.It must be borne in mind that the plates are used for floors or parquet of wood, and blocks - for future floors, which are covered with linoleum.

Beadless mounting also has its own characteristics. In particular, precast concrete slabs must be supported on walls when installed in a wooden house in such a way that the slab comes to rest on a length of at least 100 mm. It is necessary to ensure that the edges of the plates are completely clean. This will ensure future seams are clean, which should be covered with cement mortar.

The construction of floors of monolithic reinforced concrete houses implies the presence of bearing beams made of steel, installed on previously prepared areas, installation of suspended formwork made of wooden bars (you can also use uncut board), metal pre-laying reinforcement diameters from 6 mm to 12 mm and final concreting of the slab.

Despite the fact that precast-monolithic overlappings refer to beamless technologies, beams are still used here. Between them, laid at a distance of 600 mm from each other, hollow blocks are placed. Metal reinforcement is arranged on top of the resulting surface (wire with a diameter of 5-6 mm should form a mesh of 100x100 mm). Thus, a structure is formed, which in the future will become a permanent formwork for pouring concrete M200, forming a monolithic layer.

Selection of wooden floor beams

Since in a wooden house the option of using wooden beams is most often used, it makes sense to separately consider some of the rules for choosing wood for this structural element.

Both softwood and hardwood are used to make it. The weight of such beams must correspond to the loads planned for them. Usually for interfloor floors of houses, beams with a specific weight of 230 kg / m 2 are used, for garret doors with a specific weight of 250-300 kg / m 2 (the exact choice depends on the type and weight of insulation mother)

In order to find out the total load withstand by a wooden beam, it is necessary to determine the sum of the specific gravity of the beam and the temporary load per square meter. The temporary load for interfloor overlap is 200 kg / m 2 , for the attic - 100 kg / m 2 .

With regard to the consumption of wood for the manufacture of beams, beams are considered the most economical, beams whose thickness is 5 cm and height is 15-18 cm.

If these and some other conditions will be sustained by the builders, the house should get strong and reliable for many years.