The circular saw blade consists of a steel blade (disk body) and carbide tipped plates in the form of cutters, the shape of which may be different. In order to properly sharpen a disk, you need to know the geometry of the tooth and the basic rules for sharpening.

To properly sharpen a disk, you need to know the geometry of the tooth, as well as the basic rules for sharpening.

Geometry of saw teeth Alloys for the manufacture of these tackles may be different. Domestic manufacturers mainly use tungsten-cobalt alloys. Foreign manufacturers use their technological compositions. The characteristics of a particular composition will depend not only on its chemical characteristics, but also on what size the carbide phase grain is used. Small grit will provide the greatest parameters of hardness and strength, which will have the material.

Circular saw teeth can have various geometric shapes. Among them there are several basic forms:

Different discs for different materials.

- The tooth is a straight form.

- Oblique tooth shape.

- Trapezoidal shape of the tooth.

- A tooth of conical shape.

Saws, which have straight teeth, are used to perform rapid longitudinal sawing. At the same time, the quality of such a cut will be quite low.

An oblique tooth can have a right or left angle of inclination. Very often, circular saws can be made with an alternately beveled tooth, i.e., when the teeth with the left and right angle are repeated in turn. Such saws are used for cutting chipboard in the longitudinal and transverse direction. Such a constructive form will avoid the appearance of various chips on the surface of the material being processed. The saw, the tooth of which is made in the shape of a trapezoid, can be used for sawing MDF material. The peculiarity of such saws lies in the low wear of the tooth material and the rather low cutting speed. Very often, the trapezoid shaped teeth alternate with straight lines, which are used for a cleaner cut.

Saws with conical teeth are used for auxiliary work when trimming the upper or lower laminated layer. Such a saw will protect against chipping and save the surface of the material being processed.

Sharpening rules

An oblique tooth can have a right or left angle of inclination.

To understand how to sharpen a disk correctly, you need to know that the main wear of its tooth falls on the upper cutting edge. This edge is rounded during operation. The size of the rounded layer can reach up to 0.2-0.3 mm. The front face of the surface wears out quickly.

To perform such work you will need the following equipment:

- Sharpening machine.

- Pendulum protractor.

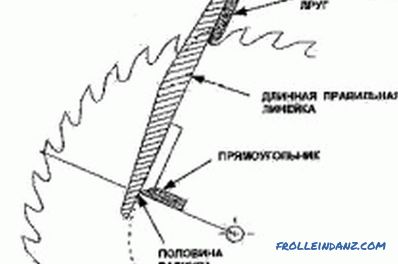

The process of sharpening a saw that has a straight tooth must be performed along a plane located in front. To do this, it must be installed in the mandrel in a horizontal position.

Then, using the adjustment screws on the sharpening machine, you need to set the required angle at which to grind. The saw blade must be moved in such a way as to ensure the closest fit to the surface of the abrasive wheel.

The thickness of the layer removed from the material will be adjusted by the force of the clamp. After the first tooth is sharpened, the disc should be moved away from the grinding wheel. After that, it must be rearranged one step and continue the process. So consistently need to sharpen all carbide inserts.

Sharpening circular saw.

Sharpening of the bevelled surface of carbide brazing can be performed both along its front plane and along its rear. The difference from sharpening the tacking of a disk with a straight surface will be that such a sawing disk must be positioned at an angle that will correspond to the angle of inclination of the tooth.

To determine the required angle of installation, use a pendulum protractor. Initially, you want to set the angle with a positive value (+8, +10, etc.). Sharpening needs to be done through the tooth, so the first half of the disc plates are processed. After completing this work, the required angle of inclination is changed to negative and the second half of the teeth is processed.

The back plane of the hitch is a little harder to sharpen. For this, a machine is needed, the design of which will allow the circular saw to be installed so that the rear plane of the saw teeth is parallel to the plane of the grinding wheel.

Work without a machine and quality of work done

You can sharpen a circular saw not only with a special machine, but also with ancillary tools.This method can be used in the case when there are no means and desire to acquire a sharpening machine. Most people use this hand-held tool infrequently, so there is no need to buy additional devices.

If there is a conventional emery machine, you can perform all the required procedures with it. For convenience, you need to make a device that allows you to fix the saw in the desired position relative to the abrasive element. To do this, fit the usual metal stand, the surface of which will be located at the same level with the axis of the abrasive wheel.

On this stand, you need to put a circular saw blade in such a way that it lies in the required plane relative to the surface. Fastening it can be done with the help of bolts, which simultaneously help to make the adjustment of the angle of inclination.

The absence of chips and various cracks on the surface of the saw helps to verify the quality of the work performed. The radii of rounding of all cutting edges should be within the following limits: 0,012-0,015 mm. When conducting a visual inspection on their surface should be no glare.

By following the rules for performing work, you can confidently use a circular saw without frequent replacement of the saw blades. And the cutting part of them will perform high-quality cutting of the necessary products and materials without spoiling their surface.

Didn't find the answer in the article? More information on the topic:

-

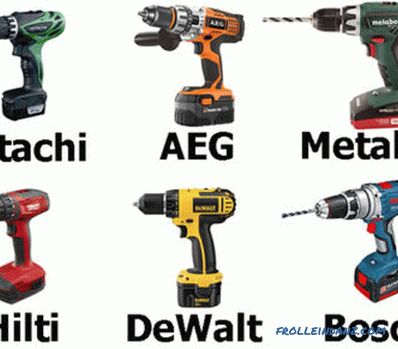

Choosing the right home screwdriver

A few tips on what criteria you should pay attention to when choosing a screwdriver. Accumulators, shock functions, power supply voltage. What can be included.

-

How to choose the right jigsaw for home?

Help in choosing a jigsaw: how to choose the right one. What to look for when choosing a tool for the home. Selection of a suitable engine power. The choice of material manufacturing soles fretsaw.