High humidity and constant temperature fluctuations are the eternal satellites of kitchens and bathrooms. High performance, presentable appearance and ease of installation - these are just some of the positive features that favor aluminum slatted ceilings. We invite you to familiarize yourself with the features of this design and its installation technology. In this article, we will tell you how to make an aluminum ceiling with your own hands, show photos and video instructions.

Specifications

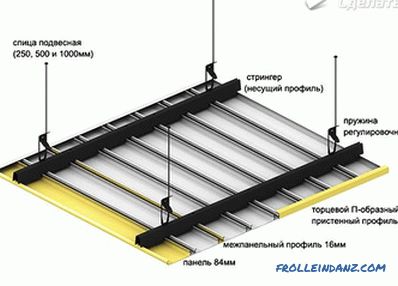

Slatted ceilings are one type of suspended ceiling. The suspension system allows you to mount rails made of different materials, including aluminum. They are made of plastic, aluminum or steel tape, having a thickness of 0.4-0.7 mm, a length of up to 6 m and a width of 50-300 mm.

If you order blanks for the rack ceiling according to individual sizes, then you will be given the length of the slats with an accuracy of up to 1 mm.

Installation of a slatted aluminum ceiling is made only after plastering is completed and the walls are completely dried and the floor is finished.

Types of rails

If you decide to install a ceiling made of aluminum panels in the bathroom or in the kitchen, you will not regret it in the slightest way and durable, but fits in almost any design. A large assortment of rails can satisfy even the most demanding customers. Reiki are smooth and perforated, matte and glossy. They mimic the texture of wood and even skin. As for the shape of the rails, they are rounded and rectangular. A huge number of colors and shades is simply amazing. Reiki set along, across the ceiling and even diagonally. Thus, you can visually reduce or increase the space.

Such ceilings are still distinguished by inter-river joints. With open mounting, small gaps remain between the slats, equal to 15 mm. The decorative profile is mounted on them. When docked, aluminum panels overlap each other. There are also such slats, which are joined close together, due to which a deaf joint is obtained, that is, without cracks.

What is the suspension system

A comb or a universal carrier tire, an angular profile, and an adjustable suspension are the main components of the suspension system. The comb represents a level from galvanization with special clamps in which mount and fasten laths.

As for the suspension, it consists of a rod and a bracket. In this case, the rod is attached to the main ceiling, and the bracket - to the carrier comb. Installation of a suspended ceiling is carried out at a distance of 5-12 cm from the main one. This distance is determined individually, depending on the communications located on the ceiling and personal preferences.

Calculation and purchase of materials

If you have already decided on the color and type of ceiling, then you need to calculate the amount of materials:

- Measure the perimeter of the ceiling. This measurement will indicate the required number of purchases of the U-shaped profile, which is fixed on the walls, which will help to accurately adjoin the ceiling to the walls.

- Calculate the length of the dies. To do this, make a ceiling marking, perpendicular to the direction of the decorative panels, in increments of up to 1 m.

- Determine the area of the ceiling covering. To do this, calculate the total area of the room.

After that, you can buy the necessary set of materials for arranging the aluminum ceiling, according to the calculations you made.

Tools

Before proceeding with the installation of an aluminum slatted ceiling, you will need to assemble the following tools and materials:

- Kit for the ceiling with profiles, panels and stringers.

- Punch.

- Dowel-nails and screws.

- Suspension elements.

- Building level, roulette, marker and ruler.

- Screwdriver.

- Pliers.

- Drill.

- Knife and scissors for metal.

Marking

If you mark the ceiling correctly, then the installation will take place without any difficulty. So first of all, mark the perimeter. This is necessary for mounting the U-shaped profile. If you are dealing with a perfect ceiling, then you are extremely lucky. In this case, you just need to put a line at the desired height from the ceiling.

In the process of marking the perimeter on the ceiling, which has a different level, you will have to carry out more complex calculations. The indent from the edge of the wall in this case will completely depend on the filling of the interceiling space.

If no communications are hidden in the ceiling, then the distance from the draft ceiling should be minimal, namely 5 cm. But, before making the markup, decide whether you want to install lighting devices on the ceiling . If so, an indent of 5 cm will not be enough.

Now markup for stringers. All the lines you have planned should be parallel to the side wall and between each other, and perpendicular to the end wall and the direction of the individual panels.

Fastening the supporting elements

Fix the U-profile with the help of dowels. Set aside from the edges of 5 cm, and then make holes with a drill. The step between them for fasteners should be approximately 0.5 m.

Holes should be drilled from the outside of the profile. This event will allow you to avoid the formation of burrs, which subsequently prevent the profile against the wall. Prepare the hangers in accordance with the markings. Adjustable suspensions make it possible to level the ceiling. Extreme points should be located from the end walls at a distance of 30-40 cm. Follow intermediate points in 1.2-1.5 m increments. Fix the stringers, which will subsequently be attached aluminum strips. A small gap of about 1 cm should remain between the profile attached to the wall and the stringers. It is important to observe this condition so that at temperature drops the finished ceiling does not deform.

Assembly

Before installing the ceiling structure, cut panels of a given length. It is important to make them 3-5 mm shorter than the distance between the profiles into which the end sides of the panels will later be inserted. Now it is time to assemble the surface of the ceiling. Insert the panels into the stringers until a characteristic click indicates that the rails are fixed on the comb.

If the last panel does not fit, then nothing remains but to cut it off. Mark the cut points, then make perpendicular cuts on the removable side of the panel. Panel segments formed by notches should be broken off by bending / unbending aluminum. Fill the rail in profile, bolted to the wall, cut off the side, and fix the other edge on the stringers.

To make this process faster, set the trimmed panel to the last but one and shorten the last panel by 14 mm.

When sequentially installing the rails, you must diagonally wind them into profiles bolted to the wall. In contrast, the last panel must first be shifted to the side, getting the first edge of it in profile as much as possible. Thus, both ends of the panel are evenly positioned in relation to the wall. Now you can fix the panel on the carrier bus.

Additional recommendations

Spotlights are in better harmony with slatted ceilings. For this pre-made holes for them. Draw a circle of the desired diameter in the place of installation of the lamp. From the center of the circle to the outside line, make cuts along the radius. To do this you will need scissors for metal. Curl the petals to the inside of the ceiling. Installation of the lamp will be better if you make narrow petals.

When installing an aluminum ceiling ceiling, make sure that the integrity of the finishing layer of the panels is not disturbed in the process. Scuffing, scratches and other mechanical damage will only worsen the appearance of the finished ceiling.

Anodizing of panels provides the most stable and durable coating, as opposed to other types of decorative finishes.

Operational Features

Aluminum ceilings get dirty more quickly in the kitchen. However, to care for them is quite simple. They are not afraid of water. This means that the surfaces of such ceilings can be sponge-washed in a soapy solution.

Rugged aluminum ceilings are environmentally safe, so you can even use them in the bedroom and children's room.

When choosing aluminum ceilings, it is better to purchase quality ceiling coverings with a protective film. It will protect the ceiling from temperature extremes, dirt, moisture and dirt. When properly installed, your ceiling will retain its appearance for a long time. The installation of a slatted ceiling resembles a designer's assembly. If you already have experience in this business, we invite you to share it in the comments to the article. Have questions? In this case, ask them to our site specialist.

Video

We suggest you look at step by step instructions on how to make an aluminum ceiling yourself: