If you set yourself the task to build a building from a bar, you will need to know with precision how much raw material will be left in the process. Most often it is necessary to deal with the specified material and with edged boards. It is necessary to correctly calculate the dimensions of the timber so that it does not turn out to be too small, and also in order to save the family budget as much as possible. Usually, the parameters are fixed and are specified in all instructions for the construction case.

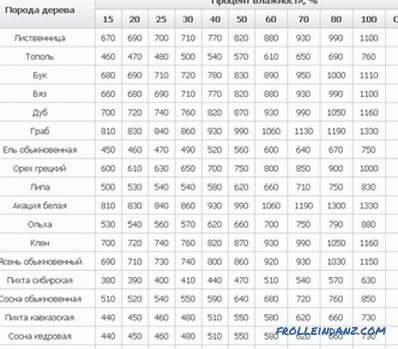

Density table of wood of different humidity.

What you need to know before making or purchasing?

During production, the following dimensional parameters are set: 150x150 mm, 100x100 mm, 100x150 mm and 180x180 mm. Lumber is also used smaller, such as 50x50 mm. They can be 6 m long, and other sizes are possible with individual production, but they are relatively expensive. The raw materials for manufacturing are mainly conifers. They are easy to handle and maintain. Transportation does not take a lot of time and money, because such trees grow in our area.

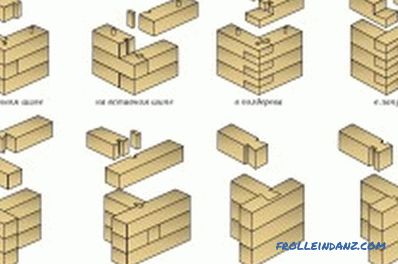

Methods for joining timber without residue.

How exactly according to the parameters to find out what is timber, and not a board? It matters if you decide to make it yourself. In this case, the cut along the width of the log should be at least 100 mm. However, if the thickness of a piece of wood is 2 times less than the width, this means that you are dealing with a board.

It is necessary to remember some rules based on characteristics:

- When you need to build a dwelling, you should not give preference to a section of 100x100, because in the frosty season the walls will pass the cold.

- For the construction of ancillary buildings such indicators are quite fit. It all depends on what weather conditions you live in.

- A section of 100x150 will be suitable for the construction of a summer house or a sauna, while the thickness of the structure will be identical to the previous one.

- This profile is ideally applicable in the construction of partitions.

Distinctive features of some types

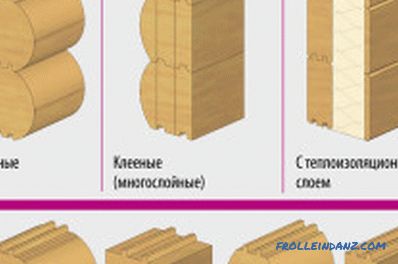

Types of lumber and logs.

It is worth noting that sometimes the length of the timber can be 5.5 m (when you buy it ready). Do not be lazy to take a measuring tape and make sure with your own eyes. Timber can be of several types:

- Profiled.

- Solid.

- Glued.

The first view has the standard parameters: 100x100, 100x150, 150x150, 200x200. Thickness can be up to 200 mm, depending on what and preference is given to a particular material for the construction of various buildings.

A 200 mm thick timber is used in housing construction for people to live in it. These designs are characterized by increased strength and stability. They are warm at any time of the year. The price here is high, however, if you buy in the winter, everything will be cheaper than in the summer or spring.

The initial dimensions during processing are reduced to 140x190. A dwelling made from this type of material is often complex, so an individual ordering system in a factory is possible. The advantages of this type are the following characteristics:

- Dimensions are tracked with high accuracy.

- Appearance due to straight and sharp lines.

- Increased durability of factory joints.

- There are no slots.

The one-piece type has a width greater than 50 mm. It is used in the construction of walls, roofs, overlapping structures.

In profile and diameter it reaches 220 mm. Today, the non-profile view is the most popular.

But the glued type consists of several boards connected with glue. It takes into account the individual parameters of each of the 2-5 components.

Lumber for the house can be made independently. But if you still decide to purchase, bring dimensional devices with you to be sure of the expediency of the purchase.

Didn't find the answer in the article? More information on the topic:

-

How and how to sheathe a house from a bar with your own hands ?

Recommendations on how to sheathe a house from a bar. Use of vinyl siding and wall paneling, block house and metal siding, fiber cement and thermopanels. Tools required for plating.

-

Which is better: plywood or drywall?

So what is better, plywood or drywall, those who come across materials for the first time ask themselves the question. Both of these materials are quite economical and are used almost always.