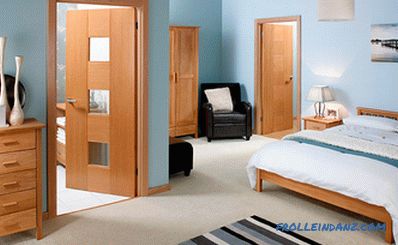

The interior of the room is formed by a combination of a set of elements, materials and building structures. The types of interior doors on the market are varied in design and materials from which they are made. They differ in design, thereby ensuring the possibility of their use in rooms with different stylistics.

The choice of interior doors for a country house, apartment or office is carried out on the basis of a number of conditions: attractive appearance and matching the style of the room; structural reliability; way of opening.

The owner of the room has the choice between purchasing ready-made doors in a retail network or an order for its production in a specialized company. The range of building structures in this market segment is huge. There are relatively inexpensive samples for the general consumer and piece goods for wealthy clients.

Difference of interior doors by device

Until recently, the main material for the manufacture of such structures was exclusively wood. The geometric dimensions and physical properties of the boards used in this process determine the basic methods for the manufacture of doors.

By device, the products are:

Pane

Shield

Each of these structures has its own advantages and features that must be considered when choosing.

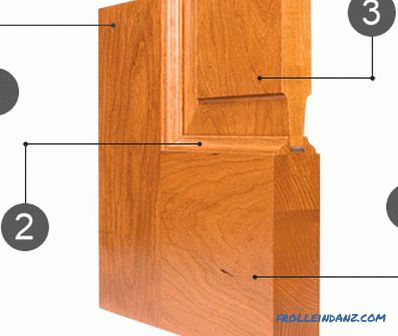

Paneled doors

Paneled doors have a rather complicated device, which consists of the following elements:

- Standing in front;

- Baguette;

- Panel;

- Lower and upper tsarga.

The supporting structure is made of solid boards and is a grid with several openings. The frame consists of vertical and horizontal elements, joined together by glued spike joints.

The openings in the frame are filled with shaped panels that are fixed in different ways. This may be thin Reiki-beadings, and tongue-and-groove joints. Large width natural wood panels are made from a blank that is glued together from two boards. This eliminates the possibility of cracking parts. Glass, MDF or particleboard panels are also used as fillings.

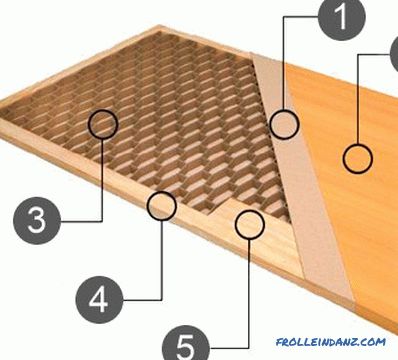

Panel doors

Components of the panel door:

- MDF;

- Veneer;

- Cellular aggregate;

- Wood frame;

- Frame reinforcement elements.

Modern panel doors are made of natural wood with MDF paneling. As a placeholder, honeycombs made of cardboard are most often used. This door has a relatively small weight, with sufficient structural strength. Door leaf of this type can be both solid and with glazed openings. The cost of such products is much lower than that of the paneled ones.

The following can act as a filler of such doors materials:

- wooden bars;

- chipboard;

- MDF;

- corrugated cardboard.

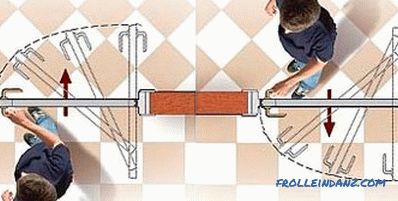

In the photo you can see the internal structure of panel doors.

Types of interior doors according to the material of manufacture and finishing

Earlier, interior doors were made exclusively of natural wood of different species. Nowadays, composite materials, polymers and glass are widely used in the production of door leaf. As coatings for interior doors of common types, laminated fiberboard panels are increasingly used.

The material used in the production determines the consumer properties and performance characteristics of the product. The cost of the door leaf depends on the type of wood, technology and method of processing exterior surfaces. One of the decisive factors when choosing products for the arrangement of premises is durability and resistance to external influences.

Doors from the array

Such constructions usually belong to the highest price category. Doors from the massif are mainly made of valuable wood species:

- hornbeam;

- oak;

- walnut;

- teak;

- ash.

Premium-class samples are often made from exotic raw materials: rosewood, Karelian birch, red, ebony or black Coromandel tree. Such doors are usually made by specialized tailor-made studio and author projects.

By design, products from an array can be either panel or shield. The latter have a smooth surface with an original pattern. Such doors are assembled from separate planks butt-gluing, for the strength of the connection are made tongue-and-groove. Each element is selected according to the pattern, and the canvas is carefully polished and polished to achieve the desired effect.

Veneered doors

To improve the appearance of products from low-cost wood species, different types of coatings are often used. One of the most common technologies is veneering. The basis of the door is usually in such a case, cheap pine lumber or chipboard. A veneer of precious wood is glued to the board on both sides, which are subsequently polished and opened with furniture lacquer.

This technology is applicable to the production of both panel doors with smooth external surfaces, and with relief. Shponirovanny products differ in environmental friendliness, for their production natural wood and special joiner's glue is used. When using them, it is necessary to maintain a certain temperature in the room and avoid humidity. Violation of these conditions leads to swelling of wood and delamination of coatings.

For the simple consumer it can be difficult to distinguish veneered doors from doors from the array, because they have a natural texture.

Plastic doors

Polymeric materials are widely used in the production of door leafs. PVC panels are veneered with frames assembled from relatively inexpensive pine boards. The structure for stiffness is reinforced with additional bars and glued with decorative plastic plates.

In the manufacture of polymeric panels, their outer surface is given a texture imitating wood of various species. Additionally, it is applied to the film with the appropriate pattern.

The advantages of such doors include:

- resistance to moisture;

- high strength;

- excellent heat and sound insulation properties.

The use of flexible seals makes such structures airtight, which allows them to be used in bathrooms, bathrooms, pools, greenhouses and winter gardens.

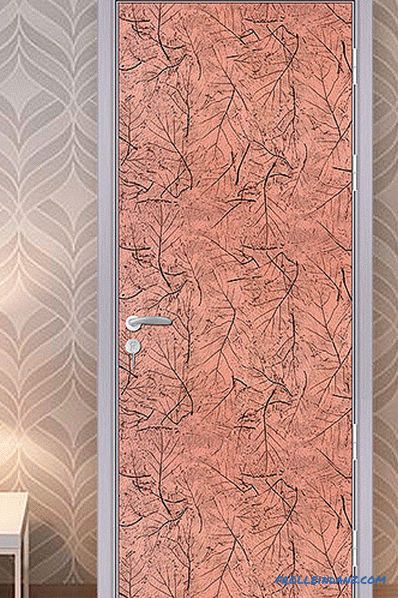

Laminated doors

The door leaf consists of a wooden frame, glued on both sides with MDF panels filled with cellular corrugated cardboard or chipboard. The outer surfaces of the cladding have a laminated coating of polyvinyl chloride film. The latter performs decorative and protective functions: protecting the structure from moisture.

The device of laminated doors filled with chipboard.

Photo: www. simpsondoor. com

Laminated doors are most prevalent due to the relatively low price. The quality of products depends on the thickness and properties of the film. The shape of the doors can be very different: from simple - flat to complex imitations - with many panels. On sale are also products with openings for glazing, which are in demand among the population.

Glass doors

In recent years, transparent designs have become increasingly popular in interiors. At home, glass doors look quite presentable. They share the space, and at the same time expands the space. For the manufacture of such doors used shock-resistant glass with a thickness of at least 8 mm, which gives them sufficient strength.

For installation of such a canvas, canopies specially designed for this purpose are used. Given the considerable weight of the products, rather high requirements for durability are imposed on the door frames. The most popular among consumers received glass sliding designs.

Types of interior doors by the method of opening

The door leaf is installed in the doorway and closes it, isolating the premises of one from another. There is a division of interior doors into several types of and their design and method of moving the sash. Below are all possible options for opening, which are used when equipping the premises.

Hinged doors

This design can be safely recognized as classic. Swing doors are mounted on hinges to the vertical rack of the box, in the closed state, the blade enters a special groove. To install this design you need a lot of space for its free movement.

The advantages of swing doors are the simplicity and reliability of the design. To achieve maximum tightness, if necessary, an elastic seal is placed along the contour. The design is supplied with locks or snaps to prevent the spontaneous opening and unauthorized entry of unauthorized persons.

Sliding doors

Such structures are used in confined spaces and partitions for dividing large rooms into zones. Sliding doors can consist of one or two doors. They are mounted on special rollers that move along guides parallel to the wall. The use of such a scheme provides ease of movement of the canvas.

Sliding doors are made of almost all possible materials: wood, composites or glass. This design is the safest of all proposed, the trajectory of the movement of the sash eliminates the possibility of injury to a person with a sharp opening.

In fact, the types of sliding doors are so extensive that we wrote a separate article about them, where we looked at them in detail.

- See article: Types of sliding doors.

Folding doors

These designs are an accordion, which consists of several hinged doors. When closing folding doors, they rotate around a vertical axis and in the extreme position are parallel to each other. Such designs occupy a middle position between sliding and swing.

Folding doors are used mainly in large openings and may consist of one or two parts, which are shifted in different directions. Usually such structures are made light enough to provide them with ease of movement. Doors often have partial glazing.

Swing doors

Such a device is a special case of a swing construction. Swing doors can be single or double, depending on the configuration of the room and the width of the opening. The box has larger dimensions than the canvas, and the canopy design allows their opening both inwards and outwards.

Swing doors can not boast of good tightness and require a lot of space to ensure its movement of its doors. The main advantage of this design is the possibility of a fairly free passage from one room to another. It is always easier to push the flap, rather than pull on yourself.

Dimensions of interior doors

The dimensions of doors and boxes for their installation are established by the current GOST 6629-88. For convenience, the data are summarized in the table:

| Web width, mm | 600 | 700 | 800 | 900 | 1100 | 2 * 600 | 2 * 700 | 2 * 900 |

| Web height, mm | 2000 | 2300 | ||||||

| Box height, mm | 2071 | 2371 | ||||||

| Box Width, mm | 670 | 770 | 870 | 970 | 1170 | 1272 | 1472 | 1872 |

The choice of the type of door depends on many factors and not least on its cost. Price category is determined by the materials, design and method of opening the product. Of great importance in the selection of designs are the size of the room and their configuration.