Land owners are increasingly making their choice in favor of building houses from a bar. An additional advantage of this solution is that with a strong desire, each owner can build a house from a bar with his own hands. Having built such a house with your own hands, you get a quality, durable, reliable and comfortable dwelling. Directly the technology of construction of such buildings is extremely simple and understandable. Of the skills to work, you will need only the experience of handling a gasoline or electric saw.

The house from a bar looks very nice. But in order for it to be reliable, at the construction stage, the timber must be treated with special means.

What kind of wood can be used to build a house from a bar?

Types of tree species.

Before you start building a house from a bar with your own hands, you need to choose the most high-quality and suitable material for work.

The main qualities of wood are strength and density. In some breeds, these figures reach the level of most metals, therefore quite high demands are made on the houses from a bar with their own hands. The walls of the building must be durable and strong. In addition, they should provide good heat and sound insulation. But there is a tree and a number of drawbacks. The main ones are low fire resistance and a tendency to sediment deformation, especially strongly manifested in the first few years after construction is completed.

Coniferous woods are the best choice for building a house from a bar. Material differs in long service life and resistance to rotting, it does not crack and does not exert a significant load on the foundation. It is important to remember that not only competent construction technology, but also the material chosen by all the rules allows you to build a good house from a bar with your own hands. So wood should be as durable and dense as possible.

Solid or profiled bar?

Types of timber.

Bar can be profiled and solid. For the construction of the house you can use the first and second option. To select a specific type of material, consider the main advantages and disadvantages of each of them.

A profiled bar for building a house provides for a profile. It may have spikes and crown grooves. Such connections are established along the entire length of the material, after which the surface is subjected to grinding. Bar for the construction of the house comes ready. The owner can only collect the construction of the resulting elements. Among the advantages of houses built from profiled timber can be distinguished:

- High resistance to deformation.

- Relatively low construction costs.

- Low complexity of construction work.

The material has an exact form, allowing to perform all construction activities in the shortest possible time and with the highest quality. Houses made from this material have a more interesting appearance and high thermal insulation characteristics.

The smooth surface of the walls can be attributed to the number of advantages of a profiled bar. They do not even need to sheathe, because they already look great. The walls of this material are protected from rotting, because they will not collect melt and rain water. The profile is calculated so that the sediments do not fall into the intervenit seams.

After shrinking a house built of a profiled bar, you will not have to waste time and effort on the caulking machine. This material provides excellent wind protection and high thermal insulation, since the crowns have a compound of sufficient density for this.

A solid timber house has a low level of thermal insulation.

But the profiled bar has its drawbacks. Firstly, it does not tolerate negative atmospheric effects very well. Secondly, the material supports combustion. In order to improve the bio-and fire-retardant properties, wood must be treated with special impregnations.

The natural moisture of the material causes cracks to appear on the timber during the warm season. Therefore, it is best to immediately look for such a material, the humidity of which is reduced to no less than 20% by chamber drying. The thickness of the walls of the house of profiled timber will not be enough for comfortable use. We'll have to perform additional outdoor insulation. After construction is completed, it will be impossible to add or change the layout.

Learn about the features of solid timber. Despite the fact that it has not the most presentable appearance, the material is still quite widely used in construction. The main advantage is relatively low cost.When preparing wood, its natural humidity is preserved, which eliminates the need for additional measures and reduces the duration of the preparatory stage.

One-piece timber can be purchased at any specialized market. You can choose exactly what you need without any problems. From the moment of ordering to delivery to the construction site, it takes an average week. The simplicity and speed of production of the material made it possible to shorten the time so much. Another big advantage of using solid timber for building a house is the absence of the need to use special equipment.

Schemes of connecting bars.

But there are also disadvantages. These include:

- Higher finishing costs. To obtain a beautiful and complete appearance of the building, it needs to be sheathed with siding or clapboard.

- When choosing a bar, you need to be extremely careful, because unscrupulous sellers offer a bad bar.

- A fungus may begin to develop on the material. The reason is the natural moisture and the failure of special drying. Of course, you can process the bar with special impregnations to destroy and prevent the return of the fungus, but it will take extra money and time.

- The intervening seams are very thoroughly purged. House of solid timber is characterized by a lower level of insulation.

- After shrinkage, the wood will crack. To prevent such damage, the walls have to be sheathed on both sides.

Preparation of materials, tools and the project

Tools for working with a bar.

Once you have decided on the appropriate type of timber, proceed to the procurement of materials, the collection of tools and the drafting of the project. If you wish, you can purchase material in a ready-made form. All bars will be trimmed to your size. The material will already have grooves, and you will only have to lay out the building like a constructor.

If you want to save material, you can prepare your own hands. If you choose this method, pay attention to the following factors:

- Wood must be healthy.

- Through and large cracks are absolutely unacceptable.

- Wood should not have signs of damage from bugs.

- Before use, the material must be treated with antiseptic compounds.

Work on the construction of a timber house will require the use of a whole set of tools, namely:

- Gasoline Saws. Instead, it will fit and electric.

- Electric drills.

- Level.

- Measuring tape.

- Hammer.

- Ax.

- Nails, screws, jute.

- Electric screwdriver.

- Punch.

After preparing the materials and tools, proceed to drawing up a project for a house from a bar. In the process, you need to accurately calculate all the necessary calculations. The project can be made independently, there is nothing difficult in it. If you wish, you can contact a specialized construction company. The specialist company will make the project in compliance with all the rules, taking into account seismic resistance and other important factors.

What should be the foundation of a log house?

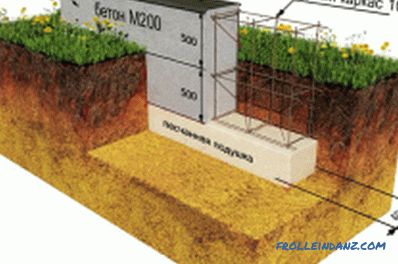

The device of the strip foundation.

Having prepared a customized project or get your hands on it, proceed to the arrangement of the foundation. The house of the timber should be built on the basis of sufficient reliability and durability.

When choosing a type of foundation, consider such parameters as:

- Basic characteristics of the soil on the site.

- Estimated base load.

- Design features.

A house of timber can be built on a concrete or wooden base. Most often a concrete foundation is poured, a brick base is laid on it, and the construction of walls from a beam begins on top of this structure. If you want to have a completely wooden structure, you can make a base of wood.

Bar-shaped house can be built on:

- In-ground foundation.

- The shallow base.

- Belt type support.

- Columnar base.

In the overwhelming majority of cases, a shallow or strip foundation is prepared for the house from a bar. Depth of the order of 50-70 cm will suffice.

After arranging the foundation, proceed to laying the timber. The most important thing is to determine the optimal assembly technology. The walls of the timber laid out in rows. Each new layer is laid on the previous one until a wall of the required height is obtained.

The bars have special grooves, due to which the logs fit snugly together. Grooves are insulated with special insulation.In order to increase the strength of the walls, it is imperative to use spikes to join the bars.

The simplified version involves the use of raw pine timber. The bars themselves weigh quite small, so that even special lifting equipment will not have to be called for construction.

In the process of self-erecting walls from a bar it is important to consider a number of basic requirements. First, all seams must be stitched. This will eliminate wind blowing through the walls. Secondly, the walls themselves are treated with special impregnations to increase the fire resistance and strength.

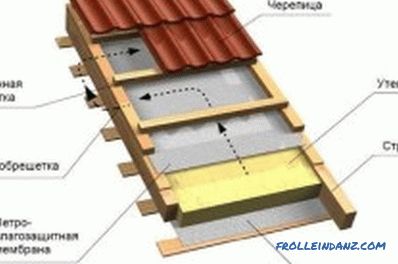

Roof, floor and finish construction

Roofing of a wooden house from a bar.

Quite often, developers try to save money on building a house from a bar. And they do it with the help of the roof, using some cheap materials, for example, ondulin. But to save on material when building a roof is absolutely not recommended. This part of the house can have a variety of options for execution, it all depends on the roof and roof systems. Each site is recommended to equip with the use of boards of different sizes. For example, the rafters are assembled from boards of 150x40 mm, and for the device of braces and struts, material 100x40 mm is taken.

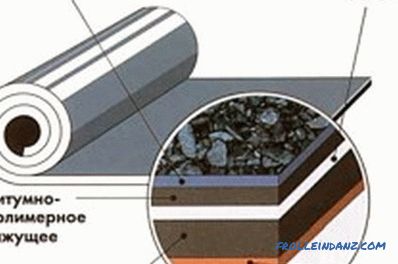

When arranging the floor and choosing the floor, the choice is also predominantly personal. The only required point is the waterproofing of the ceiling and floor. In particular, you need to carefully approach the issue of waterproofing basement and basement premises. The floor is waterproofed prior to the screed or leveling. In a wooden house you can use:

- Roll waterproofing.

- Lubricants.

- Penetrating moisture protection.

- injectors.

Scheme of the roll waterproofing device.

Socles and basements without any problems, waterproof themselves. There will be no difficulties and when processing floors of other parts of the house. Choose the most suitable material for you and proceed to its installation in accordance with the technology.

Floor - one of the main components of the interior of the home. The aesthetics of the internal design directly depends on its device. Therefore, the choice of coverage, too, must be approached with skill. On the modern market there is a large range of flooring, namely:

- Wood based coatings. This category includes parquet boards and parquet.

- Cork coating.

- Laminated panels.

- Linoleum.

- Tile for the floor.

- Carpets of various kinds.

Each option has its advantages and disadvantages.

Wood-based flooring is best suited for wood flooring: parquet and laminate flooring is the best option, such a material is simple and easy to install.

As for more modern materials, then with their installation you will not have any problems. Focus on your taste preferences and affordable budget.

Recommendations for finishing the house

Finally, the installation of interior doors, partitions and window frames is performed. The draft floor is laid, then the selected heater is installed, the final component of the floor and the finish coat. It gets off the ceiling. At this stage it is necessary to equip the water supply, heating, sewage and energy supply systems.

The exterior finish is selected by the owner on his own. If desired, the house can be left without any exterior decoration, if the appearance and quality of the source material allows it. If you want to get a different look, you can paint the house, sheathe it with siding, clapboard or trim with other available materials.

It is in this sequence that the construction of a house from a bar is carried out. Following the technology, you can get a reliable, comfortable and durable structure, without attracting third-party specialists. Good luck!