As is well known, the brazier is called a special device with the help of which anyone can cook kebabs or barbecues on coals. You can purchase the finished structure in the store or make it yourself.

Externally, these devices are a metal box, welded or assembled from sheet blanks with a thickness of about 1.5-3.0 mm. Such products have a number of indisputable advantages:

- ease of manufacture;

- easy handling;

- increased fire safety;

- relatively low cost.

Materials and tools

Self-made barbecue

Self-made barbecue

The following tools will be needed and materials:

- iron sheet of a given size;

- set of fixing bolts;

- welding machine of any type;

- electric drill with drill set;

- Bulgarian with a set of discs for metal;

- measuring tape.

Before starting work, you should decide on the size of the grill. For a small family, a brazier with a size of 50 * 30 cm is quite enough, while for a large friendly company, its dimensions should be selected individually (by the number of permanently present team members). When choosing dimensions, such parameter as the luggage capacity of your personal car should be taken into account.

For making barbecue, you should use a steel sheet with a thickness of at least 1 mm, since the thicker the iron is, the longer the finished fixture will last. The legs for the brazier can be made of the same metal, forming a rigid structure from the strips (in the form of alternating corners).

Assembly

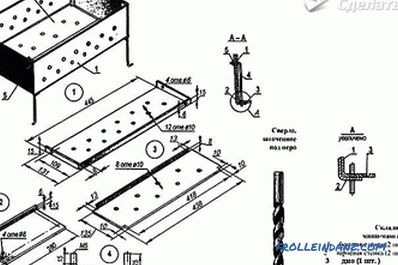

Brazier scheme

Brazier scheme

In the event that At your disposal there is a welding machine, then you can make a brazier from separate blanks very simply. In the course of assembling the structure, pre-marked and cut sheet blanks are molded so that stripes are formed at their edges, which are located at an angle of 90 degrees to the base sheet. Then they are welded along the butt line along the entire length of the blanks, after which a bottom is welded to the resulting box, in which holes are made in advance for dumping the ash into a separate section.

The brazier legs are recommended to be bolted, which allows you to easily dismantle them (for example, if necessary, for transportation).

In the absence of a welding unit, the manufacture of the frame is carried out with the help of bolted joints. At the same time, in advance prepared blanks, it will be necessary to drill at least three holes of the appropriate size - along the edges and in the central part of the sheets that are joined together.

The strips are applied with curved edges to the bottom of the box and bolted through the prepared holes. The safety factor of this design is quite enough to withstand the load from the fuel placed in the brazier.

At the end of the frame assembly, holes of 2-3 cm in size (with a step of about 4-5 cm) are drilled in its side walls at a height of about 3 cm from the bottom. These holes will serve to obtain an air draft or to “inflate” the coals.

A few tips from experienced craftsmen

Brazier with a cleaver

Brazier with a cleaver

Read the next recommendations:

- Before using new iron sheets, it is advisable to pre-ignite them with a blowtorch to remove a layer of factory protective coating.

- Support for the barbecue is best made removable, making it easy to transport it to the place of the picnic. These legs can be easily made from the corners, which are fixed at the corners of the structure by means of bolts.

- The height of the firebox is selected from the calculation so that the meat does not burn when it is cooked in the heat. It has been established experimentally that this value should be in the range of 20-25 cm.

- The blower in such devices is usually not provided, since the coals in them and so burn through quickly enough.

- Instead of a blower, you can make one of the end walls of the frame removable, which allows you to easily clean the ash collection section.

In the lower part of the structure you can make a special shelf on which it will be convenient to store fuel for barbecue (wood, wood chips or coal).

Video