So that the laminate lay down smoothly, and its locks do not break and the boards do not creak, a substrate made of special material is placed under it. A good substrate and a warmer floor will do, and absorption of extraneous sounds will help. For example, the cork substrate under the laminate showed itself very well, which will be discussed later.

Cork substrate: properties and types

One of the undoubted advantages of such a substrate is environmental friendliness. To make it, a bark of cork wood is pressed under pressure. This bark contains natural glue - suberin. It firmly connects the cork pieces, and the material becomes uniform. There is no "chemistry" in it, so there can be no release of toxic substances.

And also the cork backing keeps wonderfully warmth, and the sound delays "with a bang." In addition, it does not respond to the load - it does not rub off at all and does not cake. Here are just one category, it pumped up - by price. Unfortunately, the material from the cork has a fairly high price. Therefore, deciding to lay an economy class laminate, do not rush to buy a cork backing - this is impractical and not advisable. And if the laminate is chosen based on a long service life, it is better to choose a quality, if not very cheap, substrate.

Technical specifications of the cork:

- Density - from 220 to 260 kilograms per cubic meter.

- Humidity - no more than 7 percent.

- Heat conductivity - 0.043 watts per square meter per Kelvin.

- Sound absorption coefficient - 0.85.

- Fire resistance is high. Cork lights up with difficulty, and does not emit toxins during combustion. Fire Resistance Indicator (ASTM) - C-209.

- Strength at break - 2 kilograms per square centimeter.

The underlay can be made not only completely from cork, but also in combination with other materials. Consider these options in more detail.

Cork board

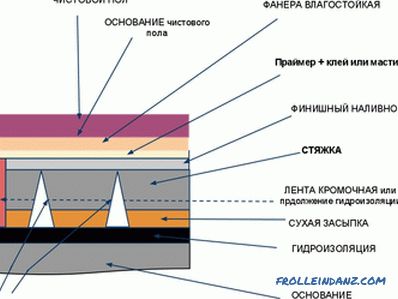

To make it, take cardboard or thick paper, on one side of which a layer of bitumen is applied. On the opposite side is a layer of pressed tube. Thanks to this design, the substrate is not only protected from moisture, but also removes excess moisture from the laminate. When laying it is not necessary to arrange additional waterproofing. By the way, put this substrate is always down cork layer. At the joints, sheets are glued with tape of sufficient width.

The rubber-cork substrate

The advantage of this material is that it absorbs sounds better than others. For its manufacture, a mixture of finely chopped cork and rubber (synthetic) is pressed. Such a substrate, like the previous version, is significantly more expensive than a material made entirely of cork. Therefore, in a normal apartment to use them is not very practical.

What is the thickness of the substrate to choose?

Many are mistaken in the belief that the thickest substrate will be the best choice. It is not possible to level the base with defects such as holes and bulges and a thick substrate. Only with the help of pre-screed, self-leveling floor or plywood flooring, you can solve this problem.

- See the material. . Leveling the floor under the laminate, depending on the base and the nature of the irregularities

As for protection against noise and heat preservation, these indicators are better for a thick substrate. True, there are nuances.

When the substrate is thicker, then it deforms more. And this is fraught with the appearance of deflections in those places where the load is large. Well, from the dents close to the breakdown of the locks of laminated boards. The best option: cork substrate for laminate - two millimeters.

How to lay the cork backing

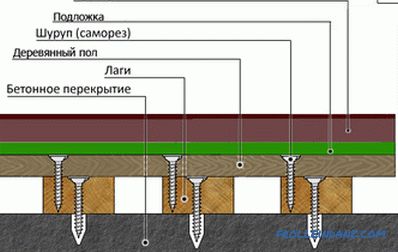

After unpacking, the material should be left for 24 hours in the room where the flooring is supposed to be changed. This is done so that the cork "gets used" to the temperature and humidity environment. Then you can start laying and - first substrate, and then the laminate. So that they do not move relative to each other, the substrate is arranged transversely to the flooring of the laminated boards.

First of all, we clean the base of the floor, if necessary, correcting all irregularities with a putty compound. If the floor is concrete, we will treat it with a special primer that protects against fungus. Otherwise, look - a mold will appear.

For protection against moisture, we take a film of polyethylene. We cut it into strips of the right size, leaving an allowance of 3 centimeters. The edge of the film should protrude 1 centimeter or 1.5 centimeters above the wall. Overlap between adjacent sheets of film do 10 or 12 centimeters. To connect them, use adhesive tape. In order not to spoil the waterproofing, never use a stapler or nails.

When we leave 1 centimeter away from the wall, we place the first sheet of substrate.

Close to the first sheet, (without overlap) we stack the next sheet. The adhesive tape for their connection should be 6 centimeters wide.The last leaf is cut a little, so that the distance to the opposite wall is also 1 centimeter.

If you are laying laminate flooring on a wooden floor, you do not need to make waterproofing, just lay the substrate on the base.

Important: never lay the substrate in two layers. Characteristics from this will not improve, but it will wear out much faster. And yet: one hundred percent traffic jam is only suitable for a hallway or living room. In the kitchen, it is better to use a more waterproof material. For example, the substrate, consisting of a combination of cork with bitumen.

Well, now that the cork substrate has been completely laid under the laminate, you can start laying the laminate itself.

To summarize

To choose both laminate and substrate to it should be based on their own tastes. It is also important how much money is in the wallet. And if you decide to fork out for expensive laminate, then remember that it will last a long time only with a good substrate. And if it is made of cork, then the safety of the floor will not have to worry for many years. Although the cork backing cannot be called cheap, it will pay back the money spent with interest.

Video: Laying laminate on a cork backing