In a properly equipped wooden well, natural water purification makes it better and more palatable than after treatment at a water treatment plant. Such a source is always available and can serve as a backup option for failures in centralized or autonomous water supply.

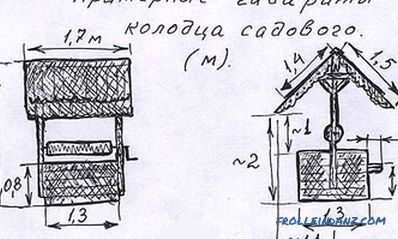

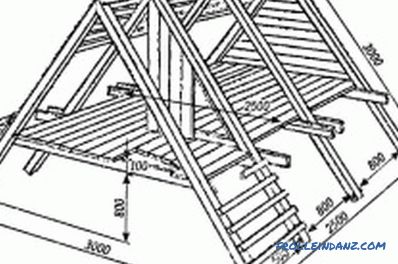

Drawing of a wooden well.

Groundwater is subdivided into 3 main types, reaching in depth from the surface: upper water, groundwater and artesian. The submarine lies at a relatively shallow depth, is not sufficiently cleansed of contaminants and cannot be used as drinking water. Artesian water is located quite deeply, the well drilled before them pours water onto the surface by gravity. Groundwater is more suitable for water supply of a country site.

The construction of the well for an independent device

The type of the well being constructed depends on the daily water consumption required. If the flow is negligible, the water will start to stagnate and rot. In order to dig and equip the well with your own hands for individual needs, it is better to choose the mine type.

At a small water intake, an imperfect wooden well is preferable. The flow of water in this case will be provided through the bottom filter. The mine is being dug into 1/3 of the aquifer, and the well’s supply will not depend on this size. Arrangement of filters on the walls of the mine is complex and slightly increases the filling of the well.

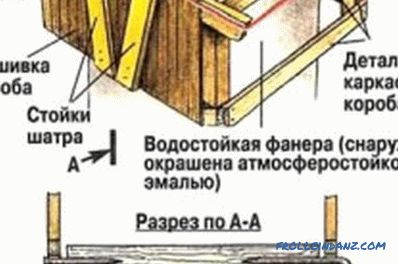

Assembly scheme of a typical house for a well.

When using wood to fasten the walls of a mine, a log cabin of logs or bars is collected on the surface. The design is put in the trunk and settles to the aquifer with gradual excavation. The crowns are built up on top of the log house. With different density of soils and the arising difficulties of penetrating a wooden fastener, other methods of mounting the structure are used.

The water intake part should be equipped with a bottom filter. With a strong dilution of the aquifer (quicksand) before the arrangement of the bottom filter, the bottom is covered with boards with preservation of cracks or with drilled holes.

The well being constructed with its own hands must have a depth of no more than 15 m. From a greater depth, raising the ground will become difficult. In the mine with a depth of less than 5 m possible penetration of surface water, polluting the water of the main aquifer.

The lateral dimensions of the mine are taken solely for reasons of convenience when it is equipped and to reduce the consumption of materials and labor costs. The bottom area of the well has almost no effect on the increase in water flow. The cross-section of the bottom is important only when the well is powered by ascending keys. With better clearing of such a source, the flow rate increases. The best for the mine is the size of the sides of 0.8-1.2 m, such parameters will allow the use of hand-held earthmoving tools and do not produce extra soil.

Selection of the location of the well

Location map for the installation of the well.

In order not to dig a well, hoping for success, it is better to contact the local hydrogeological service, where you can get information about the types of soils on the site, the depth and the composition of groundwater. If there are wells in nearby areas, you can ask your neighbors about their parameters and water quality.

A test well is being drilled to ensure complete confidence in the efficient use of the future structure. It is not recommended to equip the well, if the terrain on the site is marshy. Reliably find out about the possibility of using water from existing wells in the area for drinking can be in the district sanitary epidemiological station.

The well should be removed from septic tanks, compost heaps, buildings for livestock and other sources of pollution for a distance of at least 20 m. Do not equip it on the banks of water bodies and the slopes of ravines to avoid draining water. From the capital buildings on the site, the well should be removed by at least 5 m.

It is better to carry out the earthworks in the summer or autumn. During this period, the groundwater level is the lowest; frequent pumping of them during the digging of the mine will not be required. If it was late spring, you should wait a month after the snow melts until the aquifer is sufficiently depleted.

The technology of assembling the log of the well

The scheme of the connection of the angle of the log in the paw.

To assemble the log house, you should prepare the tools:

- benzo or electric saw, handsaw;

- ax, chisel, hammer;

- scraper and adze;

- plumb line, tape measure and level.

The log house is erected in a square shape, more often 1 * 1 m. The wood for the log is selected based on the location of the logs relative to the water. Material above the water is more susceptible to rotting than is recessed. It is better to combine the use of different species of forest.Underwater parts should be made of pine, willow or aspen, hanging over a layer of water - from larch, elm, alder or stained oak. With this combination of material well may serve more than 20 years.

Oak logs that have undergone a process of staining, in the underwater part of the well may not collapse for more than a century. But without this treatment, wood will give the water a bitter taste and change color to brown. Other types of wood are less durable and affect water quality.

Timber should be straight, non-dry. In used logs should not be areas affected by rot or insects. The bark before assembling the felling is scraped off. It is not recommended to treat the material with antiseptics or other protective compounds.

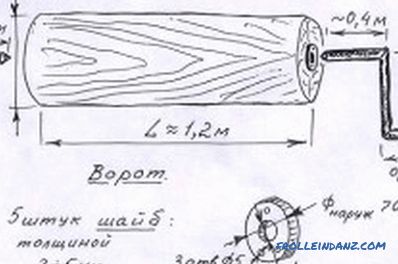

Gate scheme for a wooden well.

Logs with a diameter of 18–20 cm are used for arranging the well, larger logs are cut along. Cut down have inside log. The assembly of the log house is first performed on the surface. If installation is planned inside the mine, the crowns are prepared and laid out in advance.

In the corners of the frame, the elements are connected in a paw with no residue. Fastening produce pins with a size of 10 cm vrazbezhku vertically. For durability, adjacent rims are fastened with staples, tied at the corners in bars. In the middle of each wall at the time of installation nail boards. The logs are carefully adjusted, as caulk crevices are not allowed, tow will affect water quality.

Fastening the shaft with logs

To set up the well shaft, you will need:

- crowbars and shovels (normal and shortened);

- sledgehammer, jack, winch ;

- tripod, rope and tackle;

- buckets and buckets for dredging and silt;

- capacity under the ground;

- rope or ladder;

- pump for pumping out water;

- pebble or rubble;

- dry clay for a “clay castle”.

Roof drawing for a well.

The shaft is fastened using various technologies depending on the structure of the soil layers .

Lowering The fixing is performed at the required depth of the mine more than 6 m. The future mine shaft is marked on the surface of the selected site. Initially, excavation is carried out at 1.5-2 m. Part of the log house with the number of crowns in the initial depth is made. 4 crowns. In the lumen of the mine, carefully assembled log cabin, preventing the soil from collapsing from the walls.

The bottom is deepened by about 30 cm, under the frame the soil is removed from the middle of the wall, but left at the corners. Supports (wedge linings) are installed in the niche under the lower crown. Then the ground is selected from the corners. Supports are knocked out and the box evenly settles. As the shaft deepens over it, a tripod is set up with a chain hoist to facilitate lifting the excavated soil. For a convenient assembly of a log house over a mine, in some cases, a skeleton of logs is erected, the polyspast is mounted at a height of about 1.5 m above the ground.

A draft of a beam is made by striking a sledgehammer through a planked beam. To make it easier for the log house to settle down into the mine, on its basis a special shoe with a cutting knife is sometimes mounted. Next is the sequential deepening of the mine and building up the upper rows of the crowns. The flowing water is drained by buckets and the blast of the lower rim continues.

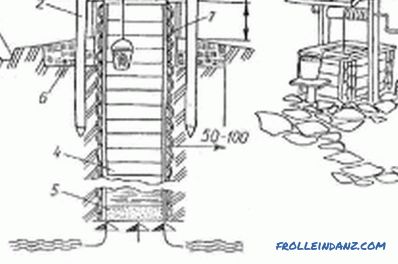

Diagram of the shaft well.

When reaching the aquifer, the mine will gradually be filled with turbid water. It is pumped out by the pump, and the mule is scooped out in buckets. The blockhouse is lowered until the appearance of volumes of water that do not allow for further burial.

After works on fastening the shaft and removing accumulated water, a bottom filter is equipped. The bottom is leveled and covered with a layer of sand (20-30 cm). The filter is formed from 3 layers of rubble or river gravel. The layers are stacked by 15-20 cm with an increase in the size of the fractions from the bottom up. The size of the fragments increases with each layer by about 6 times.

Other measures for the installation of a log cabin in the mine

If the draft of the structure is impeded, a massive load is laid on the upper crown. If the box fails to precipitate to the desired depth, further build-up of the crowns is carried out in the mine from top to bottom from the lower edge of the log house.

The crowns (pledges) added from below are made from longer logs, undermining special niches (pechury) for them. The pledges are mounted every 4-5 crowns, setting the ends of 2 logs (fingers) to the pechury by 0.5 m. The crowns installed in this way prevent the structure from sinking during further excavation. Sometimes, for fixing the part of the trunk remaining to the aquifer, a box knocked out of thick planks is lowered into the shaft.

If the required well depth is known in advance and does not exceed 5 m, the crowns can be built from the bottom of the mine.

This technology is applicable if the walls of the barrel are strong enough and the volume of water flow allows installation. The well rummages to the full depth, at the bottom are stale - sawn along the log. Boards are sewn on top, and the assembly of a log house begins on them.

With a relatively shallow depth of the well, the frame is mounted on a frame mounted above the shaft and suspended above the bottom at a height of 1 m. This will allow free excavation. Under certain hydrogeological conditions of the site, it is necessary to prevent the inflow of water from the water pipe. To preserve the purity of the water in the water intake, the external walls of the log house are upholstered with grooved boards.

Ogolovok is built with an elevation of 0.6-0.8 m above the ground. A clay castle settles around it. For this, a trench 0.5 m wide and 1 m deep is dug out around the top. A reinforced concrete pavement is made on top of the castle to prevent thawed and rainwater from entering the mine. The gate for raising of a bucket is established, the well is equipped with 2 covers.

To protect the surface structure of the well, a gable canopy is installed, hanging down 0.5 m on each side of the log house. You can build a closed building for protection from weathering.

When constructing a well with your own hands, you should be prepared for various abnormal situations related to the special properties of the soil layers. If the problem is not solved with the help of available knowledge, it is better to contact a specialist. Particular attention is paid to the safety of this kind of work.