Premium-grade quick-mix materials designed for landscaping adjacent to private homes, reputable city offices, luxury residential complexes, must meet the most stringent standards.

Serious demands are placed on natural stone, sidewalk clinker, paving stones used today for paving sidewalks, garden paths, and parking areas. It is necessary to ensure not only a beautiful appearance, but also to pay attention to the practical side, which implies the use of appropriate materials that can withstand the design loads, the mandatory adherence to the work production technology.

Traditions and adoption of innovative methods

Paving slabs can be laid on a depleted cement-sand mixture, an ordinary sand base. But stone, clinker, paving require a different approach. After all, they have quite a lot of weight. In addition, transport loads must be taken into account. These factors are causes of canvas deformation. However, there is a solution!

Quick-mix - a company of international level - managed to develop a unique tubag system that eliminates all problems. The complex is based on innovative components that provide a monolithic mix that is distinguished by rigid vertical and horizontal connections.

Consideration of the process from the point of view of chemistry

The composition of the tubag system determines its properties:

- routes, which is a pozzolanic additive from amorphous silica fume ( SiO 2 );

- calcium hydroxide, forming a dense crystal lattice, giving the solution a viscosity that blocks the pores, preventing the cement stone from leaching out of the hardened mixture.

This solution has certain advantages:

- evaporating water makes less lime on the front surface of the tile, so no efflorescence is formed;

- the solution retains its vapor permeability during hardening;

- the internal stress of the mixture changes smoothly during drying, which significantly reduces the probability of cracking;

- adding a trace gives the solution increased elasticity.

Use cases of the technology

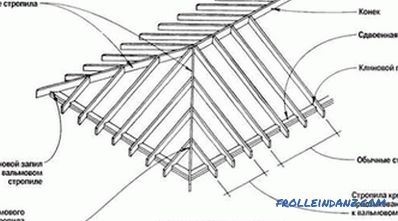

The paving stones are laid on the prepared surface

The paving stones are laid on the prepared surface

Stones or slabs are not laid on an unprepared surface. First, the base is formed - a compacted layer of rubble and sand or a waterproof concrete coating.

The type and thickness of the underlying layer determine the requirements of the project. For example, if it is necessary to ensure watertightness, then laying of the route drainage solution TDM is made, the void rate of which is from 15% to 20%. This contributes to the effective abstraction of water, preventing destructive processes.

TDM layer thickness:

- not less than 10 cm - the mixture is placed on a pad of compacted gravel or crushed stone (the coating is designed for medium and light traffic loads);

- 6 cm - concrete base.

The paving stones are laid on a fresh layer of mortar. Providing a reliable adhesive bond between the drainage and the stone is carried out by coating the inner surface of THN-flex (solution-slurry).

In some cases, there is no need for waterproof mixtures, and you can do with ordinary solutions. The main thing is to follow the rules when filling in the seams:

- the surface is pre-cleaned and moistened;

- the ready mixture gently fills the seams;

- It is better to use a rubber spatula.

Solutions

Removing seams is excluded

Removing seams is excluded

PFL 2. Created from two components. The structure is porous. Differs in frost resistance and water tightness.

PFK . One-part solution. It copes well with pedestrian and car loads. Not afraid of exposure to moisture.

PFN . Application due to frost resistance and water resistance. Transport load should not be above average.

TFP . Trace Solution. Ideal for filling seams between polygonal plates. Waterproof.

Advantages tubag

The mixture is suitable for forming round pads with different thickness of joints

The mixture is suitable for forming round pads with different thickness of joints

- The tubag system has the property of leveling the effects of voltage due to dynamic loads. As a result, the track can occur only in the case of heavy traffic of heavy vehicles, and the leaching of seams with the observance of the installation technology is almost impossible.

- When the project involves the construction of a round-shaped platform, the use of untreated stone, inevitably the appearance of seams of different widths, with the filling of which there are no problems when using a tubag.

- The mixtures are moisture resistant, resistant to reagents. Therefore, cleaning surfaces from contamination does not cause absolutely no difficulty. The material tolerates low temperatures, does not dry out when exposed to sunlight for a long time.

Video