Roofing is the most important element of the house. It protects from rain, takes on snow and wind loads. Rafters for the roof are a kind of skeleton that determines the ability of the whole structure to resist negative external influences. Designed to transfer the load from the weight of the roof to the walls and floors of the building.

The device truss system.

Features and types of truss construction

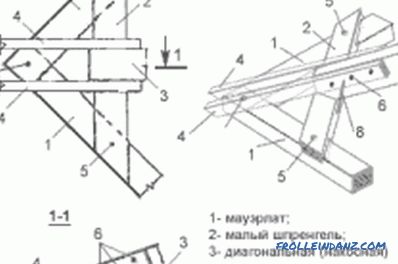

Depending on the design decision of the roof, the performance of the truss system will be different. The basis of the construction of the truss system is the truss beam itself. This beam with its lower end rests against the mauerlat (the upper frame of a frame or brick house or the upper crown of a log house). The upper end rests on another rafter or, depending on the construction, on the ridge beam.

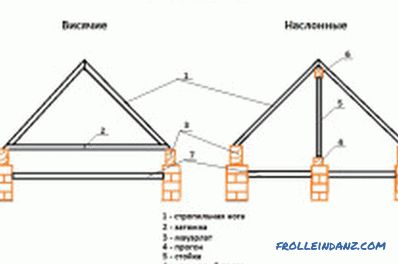

Types of rafters.

To enhance the carrying capacity for long spans, additional posts and struts are installed.

The basis of a truss structure is often a figure similar in shape to a triangle. This type of truss truss is most resistant to the loads acting on it.

According to its type of device, there are several types of roof systems:

- hanging rafters;

- slanting rafters;

- combined.

A hanging truss system assumes that trusses are supported on the walls of a building, if they are not supported on internal load-bearing walls or supports. Along with attractive simplicity, such a device has a very significant drawback - the great importance of the bursting load transmitted to the walls of the building. For its compensation, special tie-beams are used, which, depending on the location, will play the role of a floor beam (lower position) or a bolt (upper position).

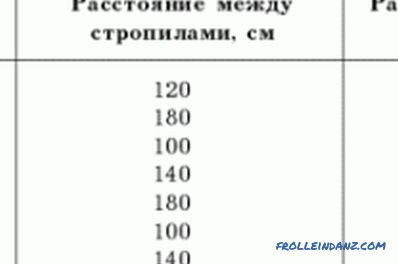

Calculation table truss system.

Moreover, it should be noted, the higher the screed is located, the greater the impact on it will be, respectively, the larger dimensions it should have. A compromise option is to use two puffs simultaneously: the top and bottom.

The suspended truss system is used when constructing a roof on houses that have an internal load-bearing wall or pillars. The ends of truss trusses, as in the previous case, rest on the mauerlat, and the middle of the span - on internal supports. Since the length of the overlapped spans in this case will be quite small, the timber for the construction of the truss system can be chosen less massive compared to the hanging structure.

When constructing a common roof over several spans, a combined roof system can be used. This approach allows you to alternate trusses made using different technologies, and opens up more freedom in the layout of the interior.

Requirements for the material and operating conditions of rafters

Pine timber or thick board is used as the main material used for the manufacture of trusses. The lumber section is chosen so as to withstand both the weight of the roof itself and the weight of the snow load characteristic of a particular region.

Variants of truss for homes.

The possibility of weakening the strength of wooden structures in case of damage by insects or mold fungi should be considered. Therefore, the main requirement for building material along with the absence of mechanical defects of wood should be the complete absence of traces of biological damage. As a preventive measure, before starting the assembly, all parts should be treated with an antiseptic solution that protects against microorganisms and insects.

Also in the process of operation, the important point is the construction and maintenance of waterproofing from the side of the roof and vapor barrier.

Tools and auxiliary materials

For the manufacture of roof structures you will need a carpenter's electric and hand tools, namely:

- saw;

- electric drill;

- hammer;

- chisel or wide chisel;

- ax;

- measuring tool.

The following materials may be useful:

- bolted fasteners or screw studs;

- mounting plates;

- galvanized screws;

- wooden pins.

Methods of connecting parts in a truss farm

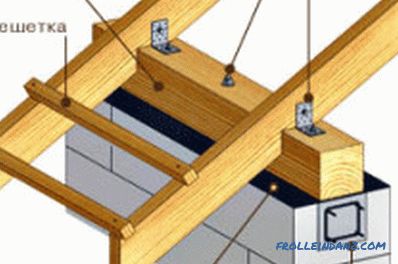

The scheme of fastening the rafters to the power plate.

In order to properly withstand the loads acting on them, the rafters must be connected to each other and to the adjacent structural elements of the building so that the forces acting on the roof are balanced by the connecting parts.

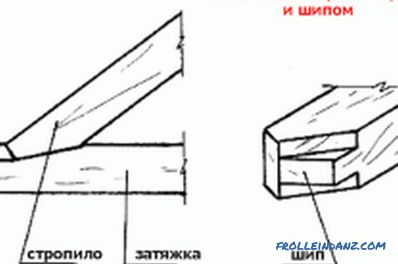

The lower end of a rafter foot is mated to the mauerlat by cutting a half-tree at an angle in half a tree with a tooth or spike type connection. The end cut is also permissible, but here it is necessary to take into account the possibility of chipping part of the wood.

When building a log house, the upper crown is used as a mauerlat, and all the cuts are made directly into it. In the frame house, this role is played by the upper frame of the frame. The most interesting situation arises when building a brick house. In this case, on the upper edge of the wall is attached strapping bar. In order to save material under the attachment of each rafter leg, it is allowed to stack your own small piece of timber. However, here, as with any economy, the strength of the roof structure will decrease.

A grater of rafter legs with a double spike will be more durable, departing from the edge by a distance of 0.25-0.30 m, which will prevent the chipping of wood. It should be borne in mind that when the rafters are cut down, the load from them will be distributed so that the tightening will work to break.

Anchor unit for attaching a diagonal truss foot to the power plate.

When designing a roof, it is advisable to provide overhangs projecting approximately 0.5 m. In this case, tightening or truss legs, depending on the adopted design will protrude beyond the walls of the house.

Additional strength for attaching a rafter foot can be achieved with bolt fasteners, dowels, or fastening plates. When making a groove and spike under the cutter, it is necessary to achieve maximum accuracy in order to prevent possible deformations in the future.

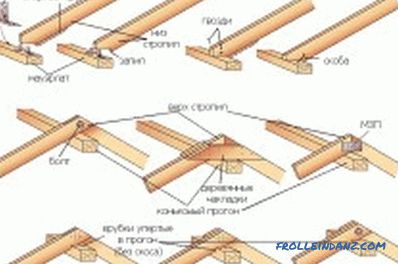

The upper ends of the rafters are fastened to each other at an angle by a hemlock in half-wood. A stronger connection will be made with a single or double slotted spike.

The spike connection holds the vertical load perfectly. From separation to the sides, it is additionally reinforced by bolting or by installing a building bracket.

Sometimes the fastening of the upper ends of the rafter legs is carried out with the help of a ridge bar.

In this case, the rafters with a tooth at a right angle cut into the timber. For greater stability against shear in the longitudinal direction, counter grooves can be made in the ridge array, where, during assembly, the rafters are inserted and fixed with additional fasteners.

Connection scheme of rafters with a tooth and a spike.

The bolt cutter prevents both horizontal separation and vertical folding of the entire structure. In most cases, to obtain greater strength, it is carried out with a frying pan (in appearance similar to the dovetail compound) in a half-tree.

When using a curtain roof, additional elements appear - racks and struts.

Racks with the lower end resting on the main wall or columnar support. Since the load on them goes in the main vertical direction, then for a reliable fastening, a hemstone in a half-tree will be quite sufficient, or with a spike in the floor between floors or tension. Alternatively, a butt joint with additional fixation by specialized mounting plates can be used.

The struts are intermediate beams connecting racks and rafters and providing additional stability to the span. Cutting strut rack and rafters is carried out at an angle in any of the above ways, or fastened with plates and screws.

Methods for installing truss

In practice, there are two ways of assembling and installing truss structures:

- installing ready-made truss trusses;

- assembling and Install truss structures directly on the roof.

In the first case, the finished structures are already coming from the manufacturer’s factory (when ordering the construction of a housing set in a specialized firm) or going directly to the construction site (for individual construction). Assembly at the construction site implies the cutting, processing and fitting of the material under a given project form directly on the ground.

Schematic representation of the rafters mounting options.

That significantly increases the convenience and safety of work. Then the finished farm rises to the top, is installed in the pre-selected grooves and secured with fasteners.

The structure can be lifted using lifting equipment. With independent construction, this method is often quite expensive and difficult. In addition, it is not always possible to drive heavy equipment to an object. Therefore, the old old-fashioned way of lifting weights to height is often used. Durable guides are installed. On them with the help of winches and a system of levers the farm is drawn up. Installation in its place is also carried out using levers and a system of blocks.In the case of small size and weight of truss farms, 2-3 people can do all the work.

Forces of one person and with significant dimensions of the constructed structure it is much more convenient to assemble all the details of the roof truss at the top, directly on the installation site. At the same time, trimming of sawn timber to size, selection of grooves and studs for fastening the mating parts is carried out for convenience on the ground.

Types of roofs using roof trusses

There are different types of roofs, each of which has its own advantages and disadvantages. Accordingly, the truss system for each type will have its own. Of the most common, there are two-slope (gable), chetyrehskatny (hip), semi-hinged two-and chetyrehskatny, mansard and polygrass roof types.

The simplest to manufacture, which means that the most reliable during independent construction of the truss system will be for a gable roof. In all other cases, it will take quite complicated calculations to carry out, and it will be necessary to spend more effort on the construction of the roof. However, they are more than pay off an attractive appearance and the possibility of expanding the usable area of the building at the expense of attic space.