Very often it turns out that after construction is over, many people understand: the next time they will act very differently. The same can be attributed to the people who built the log house with their own hands. But no one bothers to pay attention to the following recommendations, which can be considered the standard and the basis.

The house from a bar is very eco-friendly, therefore it is very popular in construction.

First of all, for the house to turn out, you need to prepare a plan and a sketch of the work. All the desired changes during the process are difficult to implement, which is only possible under the supervision of the relevant specialists so as not to break the entire system.

Construction of a house from a bar is similar in technology to the construction of a bath from a bar, but with some significant differences in levels.

Basic types of connections

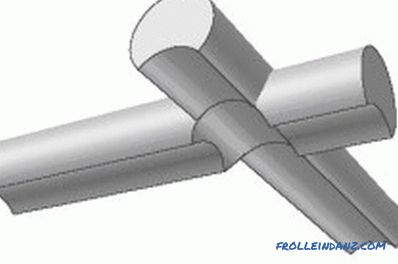

Scheme of fastening of bars using the "cup" method.

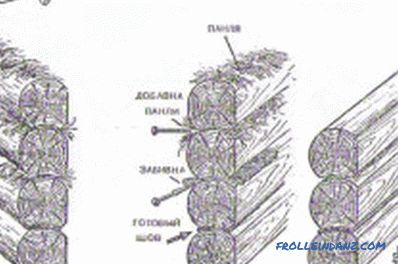

One of the important points of such a construction are corner brackets and the types of their connection between them. The most commonly used method is cutting at the ends of the groove bars, which are further adjusted and fastened with brackets. But there is a possibility that this bond may be “cold” due to erroneous marking and incorrect quarters.

Choosing a cup is a popular method for building from a log house. It is several times warmer than tenderloin. Although, for the sake of justice, it is worth saying that it is rather difficult to carry out the marking and to prepare the correct structural units of the log box. That is why this method is considered factory and is used for laminated veneer lumber.

Often used for corner joints at home, dressing with root spikes. This method is applied on the construction sites themselves. The system of marking and fastening of the nodes ensures the "warmth" of the corners, with no special efforts being made. The resulting cracks or gaps can be easily removed with inter-heater insulants, by tamping them into the “grooves”.

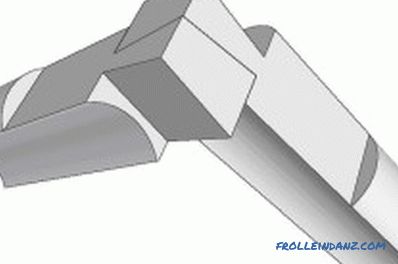

There is another option - "dovetail". This connection has warm corners, most importantly, the aesthetic appearance of the house. But in this case, the preparation of spikes and grooves has a rather complicated configuration, therefore, it is difficult to prepare it in “home” conditions.

Scheme of fastening of bars using the dovetail method.

Before starting construction with bars, it is necessary to focus on the vertical plane. Experts recommend sticking to the outside orientation. First, you should install the bars of a larger section, after which, moving upwards along the construction, the logs are taken smaller, but only in such a way that the outer wall remains in the same plane. Thus, even non-cylindrical and unequal in diameter logs look quite respectable. And on the inside of the room the difference is not even visible.

Of course, the diametric difference may initially be insignificant, which is why they do not pay attention to it, but it can increase significantly during the processing of the timber. Using the connection "root thorn" and the outer orientation, get a "cold" corner joints, as in this case, large gaps are obtained.

The interior orientation will help to provide warmth successfully, and the difference in thickness will be hidden by the outer skin. So that the "steps" were not distinguished without the presence of finishing, chamfers are removed from the bars.

Tools required for work

Tools for building a house from a bar.

In order to build a house quickly and efficiently, the following tools and materials are needed:

- construction foam;

- sealant;

- drill with drills;

- bars;

- nails;

- hammer;

- saw or power-saw bench;

- ax;

- circular saw;

- stapler with brackets;

- hacksaw;

- lever;

- brackets;

- construction level;

- building tape;

- sledgehammer;

- plane.

Connection of crowns in a box

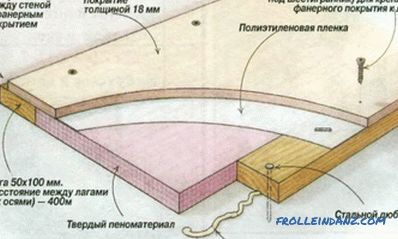

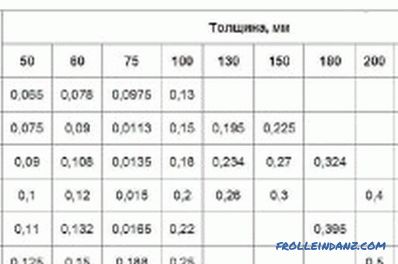

Auxiliary table for calculating the cubic capacity of a beam for building a house.

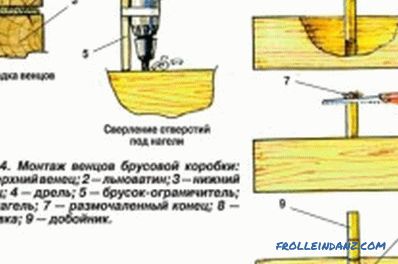

In order to join the box rims, either wooden or iron pins are selected. As an analogue, you can take nails of 20-25 cm or pieces of reinforcement.

If nails are selected, they are driven into the timber so that the caps enter into it no more than 2 cm. This is done so that, after the bars dry up, they will not hang on the caps. It is best to preliminarily prepare holes for them or use an iron rod with a cross section that is larger than the caps themselves. Nails are hammered into wood with a hammer. In the event that the core diameter is exceeded by 8 mm, the length of the hole for such a dowel should be made. Choosing a drill, you need to take into account that it must have a smaller section than the rod itself, so that it can be pressed tightly into the wood.

Speaking of nails, I would also like to note the fact that the wall is not so tough when used, unlike the use of metal pins of larger diameter, although this will make it harder for the bars to shrink. And this, in turn, threatens to hang bars. As a result, serious gaps (more than 10 mm) are formed, through which the rods will be visible. Of course, in order to eliminate such gaps, use mounting foam or sealant and only then proceed to the lining of the clapboard. But such Nagels calmly relate to working on them with a hammer.

Installation of the crown of the log box.

What about wooden dowels? They look like a peg 2.5-3 cm long with a pointed end. It is recommended to take them from hardwoods, but in the absence of those, they are also suitable from coniferous wood. You can make them with your own hands by taking boards with a diameter of 25x150 mm. It is best to prepare wooden dowels in advance, as they need time for drying.

You should know: if the dowel is prepared with your own hands, then you need to keep its correct proportion, that is, it must have a length of at least 1.5 times the thickness of the working bar. But, preparing the holes for them, the depth should be increased by 20 mm. To avoid chipping at the corner joints, the slits are made no closer than 25 cm, from which the step is measured at 150 cm.

Making dowels: features

Most often, trimming boards are used for this process. To do this, saw or sawmill boards are cut into bars 25x25cm. Such a process will take a lot of time, since such segments may take several hundred.

In order to shorten the time for harvesting the bars, it is possible to proceed differently. The board is marked diametrically into pieces of 25 cm, and the saws are carried out using a circular saw with a corresponding step. Then, with an ax, 4 sides are removed from each edge. But it should be remembered that the presence of any defects in the form of knots, oblique layers, twigs is considered a marriage and is not suitable for building a house.

Proper installation of the compactor

In modern construction of the house such heater as lnovatin has been used frequently. It has a sufficiently high thermal insulation properties and at the same time has an affordable price. After its use, the walls do not require additional caulking. Laying it occurs in 2 or 3 layers.

When working with the material, it is necessary to retreat from the outer edges by 15-20 mm, as this will prevent it from getting wet.

Warming scheme of the house from a bar with tow.

To fix it, a special construction stapler with brackets of the required size is used. If the edges hang down after attachment, they can be used for the purpose of caulking the walls.

Small tip: since the tree compresses the strips (especially after shrinkage), the sealing material must be laid in advance so that it will be further compressed well and fill all the gaps.

It should be known that the structure of flax cotton is such that it prohibits checking it through, since in this case it will wind on a drill bit (this will lead to its breakdown). Such material is difficult for wooden dowel pins, as it creates an obstacle in the holes, because of which they break. Punched with a pointed metal tube leads to the fact that its passage is clogged with batting.

That's why you should think about the holes first. Experts recommend for these purposes to use a wooden ax, which made the cruciform slots.

Recommendations for the assembly of beams in the walls

Scheme of insulation of a house from a bar with jute.

It is practically impossible to build walls by yourself. Best of all, if four people take care of this.

To deliver a bar that has a large enough mass, roll and ropes are used. For short workpieces of the pans and walls, you can not use them, but lift them manually.

Wooden bars are put on the assembled crown of the house, which, for reliability, must be fixed with nails, which are driven into the gables at a right angle. Next, do the aperture for mounting.

A reversible drill is best suited for such works, but if you don’t have one at hand, you can get out of this situation by fixing a bar-limiter. It will control the depth of the drill bit. During the drilling process, naturally, a lot of chips are formed, which can impede further work. Therefore, so that it did not work out, the drill is occasionally removed from the working holes in order to clean them from sawdust. Next, hammered pins.

The main thing is to remember about your safety. Therefore, the drilling process should be carried out on a reliable support, so as not to fall from the wall.

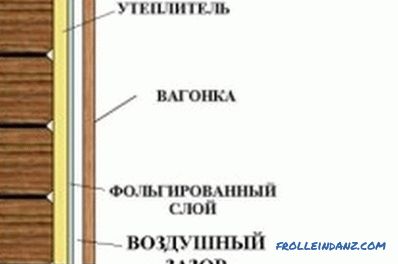

House cladding planking with clapboard.

For laying the seal, the log with the prepared stands is lifted from the lower rims of the house, so that it is possible to cover the lnovatin. There are options when the logs simply move along the wall. The holes and the walls are laid in such a way that one edge is on the wall and the other is on the scaffolding floor. After that, the sealing material is spread and fixed with a stapler. Of course, do not forget to make holes for fixings. Next, the logs are placed in the original position, the batting is laid, the dowels are driven in. Hammer should be beaten precisely in the center, otherwise there is the likelihood of cracking the nog. In addition, it may break off.

It happens like this: when working, the upper edge of the fastener starts to shake, which makes the process difficult. To eliminate this trouble with a hacksaw, the damage is removed, and the rest of the balance continues to be driven in. If there was a wreck, then it is necessary to resort to the help of the rammer in the form of a bolt. But in the case of a short debris, it is better to dismantle it with a drill and begin to hammer in a new whole nog.

Work with defective bars

Roofing of a wooden house from a bar.

Very often at construction sites of houses use defective bars. They could acquire their disadvantages both during production and during drying. But in this case there is nothing terrible, because many defects can be corrected. In such cases, just have their own characteristics of work. If there is a curved timber, then it fits only after the lower log is upholstered with batting, and lays down in such a way that the extreme holes for the dowel coincide. After that the fixture is carried out and the next hole is leveled. In this way, the entire structure is stapled.

If necessary, bend the bar and apply the lever and the bracket. It is often considered that a curved log will help straighten a large load, as a result of which such a marriage is laid out in the lower rims. But it is not.

The use of helical bars for the house is advisable only if there are spikes on both sides. Moreover, for the correct connection of one of the spikes fit under the other. With the help of an ax (butt), the twisted end is driven into a spike. In order to correct the distortions, wedges are driven in.

It is more difficult, if you get a diamond-shaped timber, which, in turn, may be screw-shaped. Aligning such a tree is unrealistic, and it will definitely affect the flatness of the walls. Therefore, experts recommend to let such logs into segments for partitions and gaps in the secondary corners. It is best to use defective wood only in the lower level of the log box.

Direct control of directions

During the construction phase, the timber must be treated with special means.

When building a house it is very important to monitor the evenness of all surfaces and the straightness of the corners. Vertical in the corners plays an important role in the construction. To make it easier to control this moment, the builders use the marking. When approaching the second or third crown, for each subsequent lumber to be settled, markup is made at a constant distance from the corner edge. If the installation will take place correctly, the lines will coincide with the vertical. To control the construction level is taken, which will indicate deviations in the case of such.

With the help of a building tape measure, you can measure the height of the corners and walls of a house. Also, the level helps to control the horizontal plane of the crowns, but for the upper edges, the eye is enough. To make sure that the wall is even, you can hang a ruler on the cord and lean it against the surface, after which deviations will be immediately visible, if there are any. Again, the roulette is used to check the wall diagonal.

Equal angles and their strict vertical provide even horizontal position and the plane of the dorsal section of the log house. All parameters and inclinations during the construction of the house need to be monitored continuously, although some points (joining of timber blanks) are tested only in a specific situation. If any deviation is detected in the flatness of the corner, either eliminate it on the spot, or replace the whole timber. Deviations in height can be eliminated by laying a heater under the bent crown, and the raised log is “lowered” with a sledge hammer.

All corners must be braced for reliability. When working with each crown, monitor the quality of the seal. When laying timber, it should be remembered that the house needs both doors and windows. But they, in turn, have some features. In particular, logs of shorter lengths are applicable for them. It should be guided by the fact that the recommended height of a single-story wall is 3 m. This will help avoid difficulties with the choice of window designs, as well as the roof.

The final step in assembling such a box will be overlapping beams for which a beam with a diameter of 100x200 mm is used. After the overlap is organized, the roof is installed. The most common option is a double or sloping roof.

The first option is considered more beautiful. Also, this installation allows minor inaccuracies in the proportions. But, despite the lighter design, such models are more scrupulous in warming.

But the second option can be used everywhere, while it is possible to create an attic under such a roof. The design, albeit more complicated, but at the expense of block mounting is quite quickly achievable.