If you need to create an even and stable coating on the concrete floor for the subsequent installation of linoleum, laminate, parquet or carpet, this is achieved by laying plywood sheets. This method allows, at minimum cost, to hide various irregularities on the main concrete pavement and dramatically raise the level of use of the subsequent layer of flooring. The use of plywood improves the thermal insulation properties of the surface.

Scheme of plywood flooring for concrete.

Before installing this material, the concrete base must be carefully leveled - in the horizontal plane it must be level and not have height differences greater than 2 mm, otherwise the concrete must be leveled using cement-based screed. Since drying can take up to 1.5-2 months (it depends on the season when repairs are being made), you can begin to select the right type of plywood for the floor and the materials and tools necessary for its installation.

How to choose the right type of material

There is a wide variety of plywood sheets on the construction market. They are of the following types:

- waterproof material (FC) - it can be used in living rooms, it is made by gluing wood veneer with a resin-based compound that does not contain phenol;

- does not sanded sheets of plywood (NS) - after finishing the laying of this type of material, you will need to additionally sand it;

- plywood (W), processed (smooth) on one side.

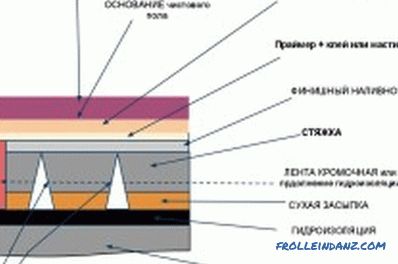

Figure 1. Floor leveling scheme.

For laying on concrete, sheets 12-15 mm thick will be needed. Still need glue, which is selected based on the following considerations:

- it should not smell,

- it should be diluted with water;

- it is desirable to choose this type can later be used as a primer.

For laying plywood on a concrete base, such adhesives are commonly used:

- Water-based glue. When using it, the sheets of material must be additionally secured with dowels. It has a drawback - its drying time is rather long.

- Adhesive composition based on a solvent. It may require primer impregnation of the screed and use dowels to strengthen the plywood. Its advantage is that it dries quickly (1 week), and the disadvantage is the presence of a strong odor.

- Two-component glue allows for quick installation of plywood. After 24 hours, you can do the grinding of the installed sheets. At the same time, no additional fixing elements will be required, which allows to install various communications (electricity, plumbing) in the laid foundation. If you work with him to use a special epoxy primer, then this type of glue can be used in the case when the screed has not yet dried.

How the fitting and cutting of plywood sheets

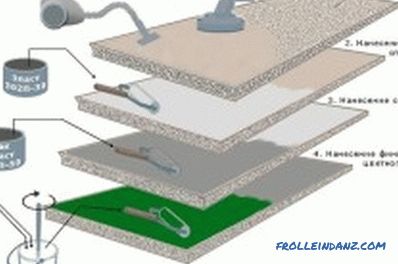

is done Figure 2. Floor finishing and primer scheme.

After acquiring the right materials and tools, you can begin to test the plywood, since its standard sheets have an uneven surface, and there may be residual stresses in them. Therefore, for temperature compensation of the material and alignment of its individual parts according to the levels of humidity, it is necessary to cut the purchased plywood into squares of 600 X 600 mm. This will allow more accurate alignment of irregularities on the concrete and will not allow undesirable voids to form.

The obtained squares inspect - there should be no traces of material separation on them. Then they should be spread over the entire surface of the floor in the room and adjusted to all angles and protrusions in the room. At the same time, it is necessary to leave seams between the squares of 0.8-1 cm wide. In places where plywood fits the walls of the room, a gap of 15-20 mm is left. Sheets of material should be laid with a certain offset - it is not recommended that they be collected in one place. Fitted squares should be numbered, and their arrangement should be sketched and then removed from the floor.

How to prepare a concrete base for work

Laying plywood is done only on a surface that must be carefully leveled. Figure 1. For this, the following operations must be carried out:

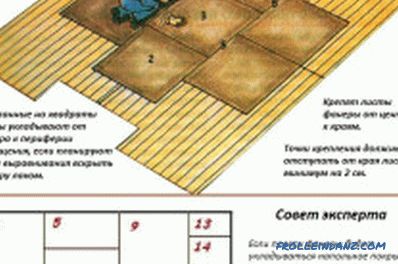

Figure 3. Layout of plywood sheets.

- Check the screed for moisture. For this purpose, a polyethylene film should be laid on top of it. It should be cut in the form of a square 100 X 100 cm. It is pressed to the floor and weights are put on top. Leave for a few days. Then they check that if there are no evaporation drops under it, then the screed can be considered quite dry, and you can begin laying plywood.

- Clean the base of debris or dust (vacuum cleaner), remove paint residues, puttyings with a sharp spatula.

- Prepared from the glue, which is subsequently glued plywood, solution for primer.It should be thoroughly diluted with a special solvent and applied to the concrete with a paint roller or a wide brush. No need to abandon this work, as the primer removes the remaining dust from the floor, captures it and glues it to the concrete. It is absorbed into the base and increases its strength, as well as improves the adhesion of the screed and coating and sharply reduces the residual moisture. This can save some of the adhesive composition.

- The primer of the screed is done before laying the plywood so that the base does not have time to become dusty. Figure 2.

How to make installation of the material to concrete

The technological process of this operation is performed in the following order:

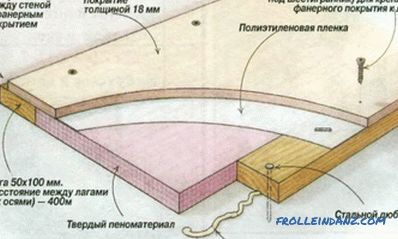

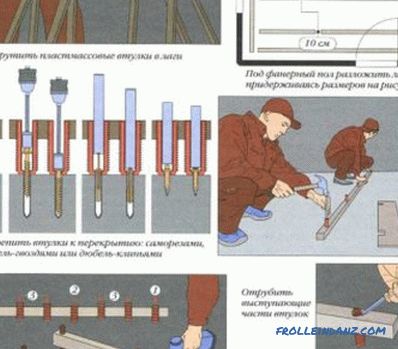

Scheme plywood flooring on logs.

- In the coupler, the holes are drilled with an electric drill according to a pre-drawn arrangement of the squares of plywood in the places of its intended fixation. They must be of such depth and diameter that a plastic dowel can enter into them, and the cap of the screw screwed into it does not protrude beyond the screed.

- An adhesive is prepared that is thoroughly mixed to prevent the formation of lumps and obtain an even mass.

- Glue some amount of glue on a notched trowel and apply it on the screed. The thickness of this layer should be 1.8-2 mm. The amount required for the use of the adhesive composition depends on the distance between the teeth of the spatula.

- Laying of plywood on a concrete floor is made according to the drawing (diagram) made in advance according to the affixed numbers. Figure 3.

- To prevent the formation of air bubbles under the material, sheets should be rolled in with a heavy metal roller.

- The plywood is drilled with holes (around the perimeter, diagonally and in the center) and inserted into them plastic dowels with screws (screws), the length of which should be 2.5–3 times the thickness of the base.

- The mounting of the squares is done with these fasteners.

Between the individual fasteners the distance is selected in the range of 150-200 mm. They should be located around the perimeter of the squares and diagonally at a distance of 20 mm from the edge of the sheet.

How to sand plywood sheets

To obtain a flat base surface, the plywood laid during installation must be carefully polished. The technological process of performing this operation is as follows:

- A special manual assembly is used - a parquet grinding machine. As a working tool used rough skin.

- The unit is turned on with circular movements, pressing it against the sheets of plywood, and grinding is carried out.

- If, after the first pass, the quality of the coating obtained is unsatisfactory, then the work is repeated using a smaller pelt.

Tools for plywood laying.

After that, there should be no burrs on the surface, which can appear in the places where the seams are located. This will help to correct small differences in height between the squares of the material.

After completing the above works, you can proceed to laying the main coating - linoleum or parquet. Before this, you first need to check with the rail (rule) the evenness of the plywood base. Its length can be 180-200 cm. Putting the tool to the floor, make sure that the distance between its surface and the laid sheets of plywood does not exceed 2 mm in height.

If this is the case, then the work is done qualitatively.

What materials and tools can be applied in

- Plywood sheets.

- Glue and special primer.

- Cement and screed sand.

- Grinding machine.

- Electric drill.

- Saw or grinder.

- Roller or brush.

- Tape measure.

- Rule.

If installation of plywood on concrete is done, then it is necessary to strictly adhere to the above described technology.

Didn't find the answer in the article? More information on the topic:

-

How to level the floor in a new building with your own hands?

Instructions on how to level the floor in a new building in case of serious drops in the horizontal surface of the base. Preparation and leveling of floors using log or cement-sand screed.