The construction of wooden houses is becoming popular again. There are several reasons for this: there is some mistrust towards modern construction materials, and their cost is too high for an average person. But in the woodworking modern technology has made a real breakthrough, which significantly reduced the time of construction of a log house from otsilindrovannogo forest.

In order for the log house to fit snugly to the foundation, it is necessary to begin the construction already on the prepared foundation.

The fact is that in the recent past carpenters carried out all the operations to prepare a tree for each wreath of a log house independently. It would seem that such a simple matter could not cause special problems for builders. But this is only apparent simplicity. In reality, the carpenters first removed the bark from the round timber, dried it, and only then carefully selected the logs in thickness, sagging. There was an alternation of the top of the tree and its butt. The whole process was controlled with a plumb line. And the density of the fit of the logs to each other and could not speak. Each log was repeatedly measured, subjected to profiling (with the help of an ax) and fit to its original position.

The log house turned out to be reliable, but its construction was carried out too slowly. But now everything has become much simpler: it is not necessary to invite a large number of carpenters to build a wooden frame.

A set of tools and materials for construction

Tools for building a log house.

For a month, 2-3 people can do all the work, the main thing is to have a clear plan and a list of all that is necessary. Special processing technology makes cylindrical logs along their entire length. And along the entire length of the log, a compensation groove is made. This technology of wood processing already eliminates the need for multiple "fit" of logs to each other. Working with such material is sheer pleasure. And a few people can make a log house, even if they do not have much experience. For construction they will need:

- galvanized construction timber;

- log construction;

- axes;

- chisels and mallets;

- winch;

- strong rope or rope;

- step-ladders or lumber for mounting scaffolding;

- chainsaw;

- drill;

- construction brackets;

- construction level;

- construction helmet.

The construction of the log house begins on the prepared foundation. Let them try to convince you that the finished log house from the manufacturer is not inferior to the log house made directly on the foundation, but you should not succumb to such advertising. A log house will never be transported so tightly to the foundation as the one you build yourself.

Waterproofing and insulation

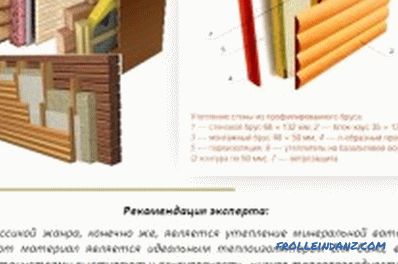

Options for warming a log house.

Before you put the first wreath, a roofing material of 3-4 layers is laid on the foundation along the entire perimeter. Waterproofing for felling is the main condition for its durability. For the first wreath, it is initially necessary to lay logs that go along the length of the house. Just put a wreath on the first log of the cross log and make marks on it at the edges of the cross log. The transverse log is removed, and on the longitudinal logs of the first wreath you need to make a crown (landing) groove. His profile may be different. Various connections of logs inside a wreath are used at construction of a felling. In the old days on both logs was made a notch at the junction, and the logs just fit. For reliability, they (logs) were connected to each other with a wooden hairpin, and cavities, obtained with poor-quality organization of compounds, were filled with moss or tow. At present, such a combination of a log wreath is also used, only modern insulation materials are used instead of tow and moss.

Alternative types of connections

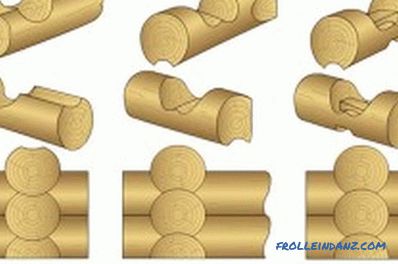

Connection options for logs in a log house.

Another type of connection of logs, which is popularly called the "Finnish corner", involves profiling the end parts of the logs at certain angles. In this case, the angles are not always profiled according to one scheme, therefore, without an exact scheme (or an experienced construction manager), you should not resort to such a connection. Better to think of something simpler than spoiling the material. The simplest (and reliable) solution is to make a triangular groove in the lower logs (perpendicular to the trunk), and give the corresponding profile to the upper log. The knot will turn out reliable and rigid. This knot has been known to carpenters since the time of Peter the Great and has been used everywhere.

If the first wreath is properly laid, the transverse log should be higher than the longitudinal elements by exactly half of its diameter. Well, then the whole process of laying logs will have to be repeated for each wreath.

Between the wreaths of the framework should be fastened by the previously obtained profiling and longitudinal groove.Most carpenters do not consider this to be a sufficient measure and use for this purpose anchors, dowels and ordinary steel brackets. The use of staples allows you to get a perfectly flat angle during construction and add additional rigidity to the structure.

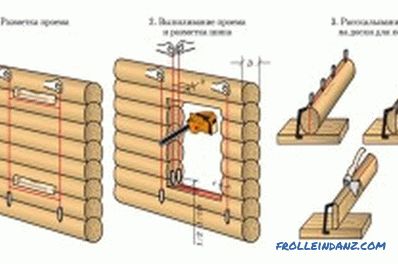

Arranging a window and a doorway

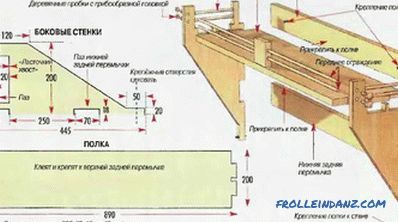

Preparing window and door openings in a wooden house.

The fastening of the wreaths of the log house on the dowels should be used near window and door openings. Here there is always the likelihood that under the action of the gravity of the whole log a certain log can “lead” several to the side. You can fix it, but you have to raise the log house, and this can greatly affect its density and integrity. Build a log cabin without subsequent modifications and allow Nagel. Simply put, logs near the above-mentioned openings sit on the pins. The distance between the pins should be from 30 to 40 cm. Additionally, sections of logs in the openings are also attached to the wooden board. Removing the mounting plate immediately before installing the door frame.

Ready-made industrial log houses

In general, the construction of a log house with your own hands is available to everyone. But you definitely cannot do without a certain amount of engineering thinking. It is much easier to assemble a log house with your own hands if you have acquired a typical construction project (or an individual project) along with all the components. Then all the construction of the house will be reminded by the designer from the DIY store. You will need to disassemble all the logs according to the marking (it is possible to decompose all the details in a certain order for reliability) and boldly undertake the construction. You do not have to do certain profiling or trim the parts. Simply assemble the parts in accordance with the attached instructions and monitor the horizontal position of each wreath, as well as the verticality of the wall at the building level.

Drying, settling and installation of the roof

After the log house has been built, there are unpurified areas of bark that will darken over time, therefore the log house needs to be polished .

A frame can not be considered completed immediately after its assembly. And to build a roof is also not desirable. Whatever moisture your material may have, additional drying out is inevitable. Shrinkage of the house will occur in any case. It is easier to correct the log cabin than to remove the roof roll, so there is no need to hurry with its installation. It is recommended to leave the frame for full shrinkage and drying for at least a year. It’s clear that you don’t want to wait so long. Then you need to start building a log house in early spring (the foundation must be ready from the beginning of last autumn). In the summer the log house will sit down a bit, you will spend additional heat and waterproofing, and by the onset of cold weather you can build a roof. That is how the construction was carried out in the old days.

The craftsmen believe that the best wooden house is not made from blanks that have undergone factory processing and received profiling, but from a roundwood.

You can agree with this opinion, if only because you will do every detail for yourself, so do not tolerate your marriage at work. Every detail will be fitted so carefully that even the use of insulation materials is practically not necessary. By the way, for these purposes, moss was used (and is used until now) not only because of the lack of other materials.

Biologists claim that mosses themselves resist the appearance of fungal diseases of wood. The symbiosis of wood and moss is also used in construction. Old construction methods and secrets were good in everything. The only bad thing is that building a house in this way can take more than one year. And the masters who understand a lot about the construction of logs from round timber are almost gone. And you personally do not have enough strength to comprehend the whole science of construction from the beginning to the end.

During the construction of a wooden house, you must remember about security measures and use personal protective equipment.

Didn't find the answer in the article? More information on the topic:

-

How to level the floor in a new building with your own hands?

Instructions on how to level the floor in a new building in case of serious drops in the horizontal surface of the base. Preparation and leveling of floors using log or cement-sand screed.

-

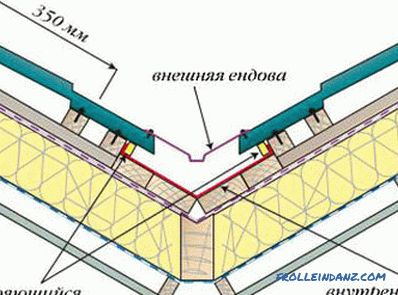

Features of the truss system

Truss Endova system: device features, necessary materials and tools. Varieties rafters installation diagram. Step by step installation instructions do-it-yourself.