When you decide to build your house, you should choose the technology of its construction. This choice depends on many factors. First of all, everyone thinks about the cost of future construction. Thus, the financial costs of building a brick or chopped house will be equal to $ 530-870 per 1 m². But the price of a frame wooden house is $ 350-625 per 1 m². Moreover, the process of building frame houses takes only about 3 months.

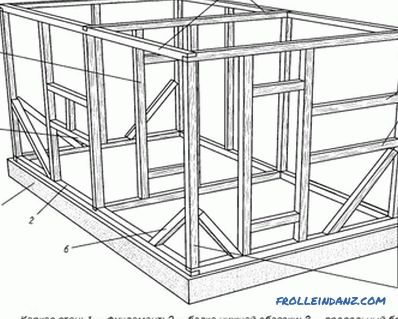

The framework of the walls.

If you decide to make the construction of a frame house with your own hands, it is important to decide whether it will be a frame-frame or frame-shield house.

Tools and materials

Framework for the assembly of a frame house.

- perforated metal brackets;

- self-tapping screws;

- nails;

- pins;

- hammer;

- cement;

- sand;

- shovel;

- shields;

- beams;

- bars;

- logs;

- boards;

- OSB or DSP plates;

- roofing material.

Features of the construction of frame houses

At the heart of the house framework are lower and upper piping and vertical wall racks. After the erection of the foundation, the house is supplied with outer and inner lining, between which is installed insulation, steam and waterproofing. As the final stage of construction is the exterior and interior.

Lower binding scheme.

If we talk about the features of the device panel and frame-frame construction, they are almost the same, as in both cases there is a frame. However, there are some differences.

Construction of the shield frame of the house is carried out from ready-made shields, which were obtained in factory conditions. Such buildings are installed mainly on the basis of the tape type. The construction of the frame of the house can not be done without the use of special equipment, which is used to deliver the material to the building site, then a crane must be used, which is needed for the installation of shields and roofing of the house.

Before installing the boards, it is necessary to install a base for them, which is made up of individual trusses made of wood and possessing upper and lower straps.

The upper trusses of the trusses that lie at the base of the shields of the house are logs, the floor will be arranged along them.

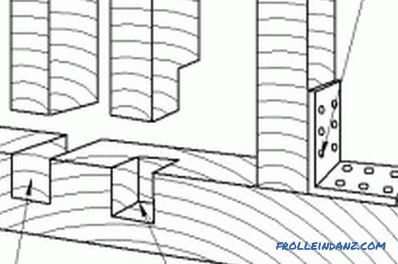

Options for attaching the vertical uprights of the frame to the bar of the bottom trim.

There is another option for mounting the base for shield walls, in its role can be a mortgage crown made of timber. In this case, the floor lags are not associated with the mortgage crown and walls.

The shields are fastened to each other according to the principle of a thorn-groove connection, metal lining can be used as an analogy of this type of fastener.

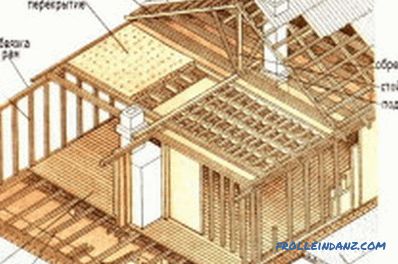

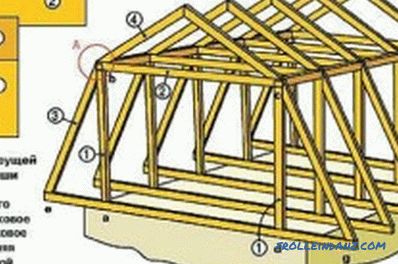

A wooden frame-type house, as a rule, has a roof of rafters. They are mounted for construction or mounted on roof trusses.

The frame of the house of shields has many advantages, including ease of wall construction, saving of time for construction, stability and durability of the walls at the expense of binding, the possibility of construction at any time of the year. In addition, such houses do not shrink, which suggests the possibility of finishing immediately after construction.

The technology for the construction of frame-frame constructions implies the arrangement of the skeleton on a fixed rim made of logs, the last of which are mounted on the foundation. The frame of the house with their own hands is made of logs or bars, but the frame stands are mated with each other with the bars of the upper and lower strapping, as well as horizontally located jumpers. The rigidity of the design is due to the stitches mounted between the uprights of the frame.

Roof trusses are installed on the side walls, and the sheathing is laid on the surface of the rafters. The construction of such a wooden house can also be made at any time, and for the work does not require special equipment.

Figure 1. Methods of connecting the bars in the corners.

If you want to build a frame house with your own hands, but you still do not know, to decline your choice in the direction of panel or frame technology, then it is worth considering that the price of frame-frame construction is 15-20% lower prices for shield house. Frame-frame houses, although there are no restrictions on the choice of forms of architectural design in contrast to the shield. However, time costs will be 40-50% more.

When covering the frame of the house, you can use boards of the 2nd grade, it will be much cheaper. For comparison: the cost of the material of the 1st grade is $ 175 for 1 m 3 , the 2nd - $ 115-135 $ for 1 m 3 . It is permissible to use OSB or DSP boards.

By building a frame house with your own hands, you free yourself from arranging boxes and niches for the location of communications, as the constructional feature of the building is the ability to hide communications within the walls of the house, however, this may hinder access to them. Laying the electrical network in the walls should be given special attention, as the walls do not have fire safety.

The frame of the house has an insignificant weight, which is 35% less than the weight of the log house, which is quite impressive, since the chopped houses are notable for their ease. In view of this, the construction of a frame house with your own hands can be carried out not only on a lightweight foundation, but also on weakly bearing soils, including sandy and swampy soils.

Sequence of construction of the frame house

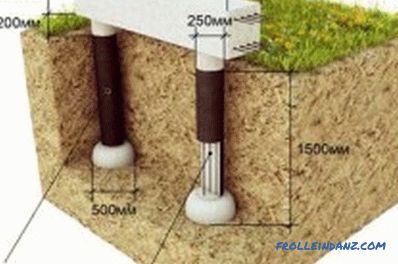

Scheme of the foundation of the frame house.

A week after laying the foundation you can begin to assemble the frame of the house. Often, in the process of casting the grillage, studs are laid into it to fix the bar of the bottom trim. If the wood intended for the framework has not been dried, then it should rather be mounted and sheathed by the RSD. Sawn timber before building should be treated with an antiseptic.

Ruberoid will be used for arranging waterproofing on the foundation and lag supports. Nails and screws will be used as fasteners.

The installation of the timber underlying the bottom trim implies its installation on the grillage on which the roofing material is laid. The timber must be laid on the grillage horizontally aligned. Irregularities can be eliminated with a solution.

To join the bottom trim bars by a method of sampling at the corners. Although there are a great many sample options, it is recommended to use 1 of 2, both can be seen in fig. 1.

In the corners of the bars can be connected with an anchor, which fixes them to the foundation. Bars can be joined with nails, the minimum length of which should be equal to 150 mm, 4 nails should be used at an angle.

In those places where the bars connect, you should drill a hole with a diameter of 20 mm, you need to drive a wooden dowel made of dried oak into it, it should be left 8-10 cm above the surface to fix the corner posts frame system.

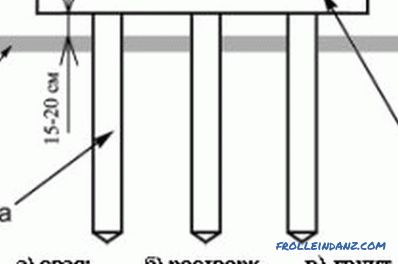

Installing the vertical uprights of the frame.

In the absence of studs laid in the foundation, the beam can be fixed to the base with anchor bolts whose diameter is 16 mm. It should be driven into the base of 100 mm.

Next, you can proceed to fixing the bottom trim beam using anchors. Holes for anchors should be drilled in grillage concrete. After in the trim boards it is necessary to form holes in places intended for anchors. Timber must be fixed to the base with nuts, which are equipped with wide washers.

As soon as the bars of the bottom trim were secured to each other and to the base, it is permissible to begin working with the vertical pillars of the frame. At this stage of building a house with their own hands should be mounted corner racks. If the bottom rail in the corners was reinforced with an anchor or nails, the corner stand should be fixed with metal corners, for which it is preferable to use reinforced corners.

If the dowels were used, then vertically disposed issues should remain, and the corner posts will have to be put on them. For what purpose in the lower end of the rack it is necessary to make a hole whose diameter is 20 mm, its depth should be 1 cm longer than the length of the protruding part of the dowel. Corner racks should be put on the nog and strengthened with booms.

The remaining racks, which make up the frame of the house, can be fixed to the harness by cutting or using galvanized metal corners, the thickness of which should be 2 mm. If you are building a house with your own hands, then you may prefer the method of fastening the racks with corners, which should be done with the help of galvanized self-tapping screws designed for woodworking.

When fastening the uprights with the cutting-in method, it is necessary to mark the bottom rail and arrange the grooves according to the rack dimensions, their depth should be equal to the limit of 30-50% of the height of the timber that makes up the bottom rail. Regardless of which method of fixing the non-angular struts, it was decided to use, they need to be loosened with booms. It is permissible to install 2 sticks on a rack or 1 long on several racks simultaneously.

If the frame of the house does not have a layout created for the walls in advance, be sure to take into account that the step between the uprights at the locations of the openings may be different. That is why now it is just possible to make a layout with dimensions.

Scheme of the structure of the pile foundation for the frame house.

The frame of the house at the corners in the process of attaching the upper trim bars should be joined by cutting.To the vertical uprights, the timber constituting the upper rail should be fixed by the same method that was chosen for fixing the posts to the lower rail. Fastening should be done with wood screws.

If the fastening is done by cutting, then before putting the bars on the vertical posts, it is necessary to form grooves for the posts in them, it is important to ensure that the slots are strictly vertical with respect to the grooves in the lower trim.

After the grooves are ready, it is permissible to install the bar into place, on vertical stands, and after fixing it to the frame, this should be done on each vertical stand using 2 nails, which should be driven 10 cm in the stand.

When building a house with your own hands, the wooden frame should gain rigidity and stability, for this purpose you should use diagonal ties, which are called cuttings. Each rack in the house should be fixed with 4 trusses, 2 of which must be placed at the bottom, 2 others - respectively at the top. But from the temporary strings that were installed earlier, you should get rid of.

If the braces have a smaller cross-section compared to the main racks, it is preferable to fix them closer to the inner lining of the frame system, this will allow a heat insulator to be positioned between the lashing and the outer lining.

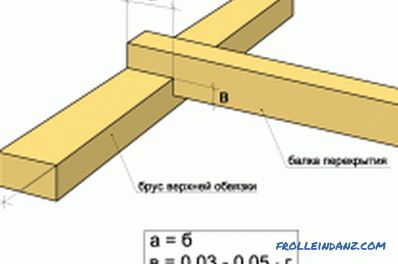

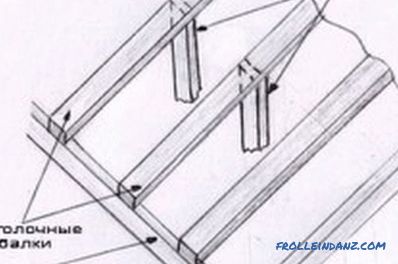

Installation of ceiling beams

Installation of ceiling beams.

The technology in which the frame house is built with your own hands, in the next step involves mounting of the shelf beams, where you can use one of the existing fixation options. So, the installation can be made using perforated metal brackets for the beam, in addition, you can mount and by means of metal corners. Another method is to mount by cutting.

It is possible to support beams by cutting in the bars that make up the upper trim by arranging grooves at the end of beams whose width is equal to the width of the beam. The depth of the groove should be 30-50% of the height of the beam. The edges of the beams should be fixed to the top trim, using 2 nails, drowning them in a rack 10 cm.

It is recommended to mark the places where the floor beams should be fixed in advance on the top trim bar.

Recommendations that help save on construction

Scheme of the supporting roof structure.

For small and short parts that will form the basis of the building frame, the remnants of long elements should be used. Also those that were bent or deformed at the time of production will do. Some materials can be used and reused.

So, the boards that were used for temporary fastening, it is permissible to cut into permanent sticks. The elements of the formwork of the base of the house will be suitable for temporary spreading. Such reuse of materials should be planned in advance, then they will have to be purchased in much smaller quantities than originally planned.

Improper storage of lumber can cause damage to them, which is detrimental to savings, so they should be carefully protected from getting wet and dirty.

It should be remembered that the burning of sawn timber, which has been treated with an antiseptic, does not relate to saving in any way. In particular, the burning of such materials can not be done in the bath, as it is dangerous to health.

A wooden frame house is not only possible to build independently, but also to do it without the additional help of professionals, such technologies allow to carry out the building process without skills in this area, because it is easier to build houses from bricks .

The house framework will be easier to assemble at home with handicrafts if you buy factory-made ready-made shields, and not wood for the framework technology. However, it will save more in the latter case. After the completion of the operational period, such houses are recommended not to be repaired, but to be demolished and rebuilt, it will be cheaper, and the foundation will no longer have to be installed, since it will not collapse under such a light construction.