Periodic renewal of the facades of suburban buildings (at least once every 25 years) aims to replace worn out and degraded finishing elements with new ones. Making repairs to the facade with your own hands, you can at the same time make some changes to the appearance of the building by partially changing the design of individual elements of the facade design.

Preparatory stage

Repair of the facade is a fairly responsible undertaking, requiring significant time and effort from the contractor, as well as the availability of certain skills for the repair work. In addition, at the preparatory stage, the schedule of upcoming repair activities should be thought out and a phased plan of upcoming works should be drawn up taking into account all possible nuances.

Warming of the facade

Warming of the facade

When planning major activities should not be overlooked and the fact that when updating the facade should take into account the security of the building from external climatic factors, namely:

- heat and sound insulation protection;

- protection against precipitation and wind;

- fire resistance.

In addition, the exterior cladding of the building should be unpretentious in maintenance, and it is also desirable that it has the ability to self-cleaning. Domestic industry produces various types of finishing materials that meet the above requirements, but in this article only some of them will be considered.

Selection of finishing material

Finishing materials for facades

Finishing materials for facades

Let's make a reservation right away that capital repair of the facade of the house can be accompanied by a complete update of its appearance through the use of new (most modern) types of finishing material.

Among the known types of facing coatings, the most popular are:

- finishing plaster mixes, which are distinguished by quite reasonable price and simplicity of the finishing process (application);

- siding decorative panels, giving the facade of the building a rather strict and attractive look;

- traditional tiled materials;

- porcelain stoneware.

Consider each of these materials in more detail.

Plastering

Using plaster mixes (most often as a preparatory layer) will hide all the existing flaws and unevenness of the surface of the facade and get quite attractive and uniform coating . Such mixtures are available in two different designs, differing in their basis, which may be ordinary cement or more expensive gypsum.

This finishing material allows to obtain a homogeneous surface, the quality of which does not depend on the type of the existing base (wood, brick or concrete).

The disadvantage of this choice is the increased labor-intensiveness of finishing works and, as a result, an increase in the repair time for the building (this is explained by the fact that all plastering works are usually done by hand).

Using siding

Facade trimmed with siding

Facade trimmed with siding

Siding coating can be used for finishing any type of base (made of wood, brick, stone or plaster); it is distinguished by its ease of installation and the following remarkable characteristics:

- durability;

- external attractiveness;

- resistance to external damaging effects;

- environmental friendliness.

When decorating surfaces made of brick or wood, the siding panels can be mounted directly on the walls of a building. In the case of facing uneven surfaces, as well as for additional insulation of the facade of the building, you will have to use a crate made of well-dried bars with a section of 50 * 50 mm.

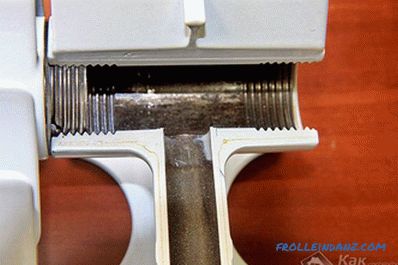

Installation of siding

Installation of siding

According to the manufacturer's instructions, installation of siding panels starts from the bottom up.

The individual panels of the kit should not adhere very tightly to other elements of the kit, that is, should be mounted with a small thermal gap. The working fixture of the plates, equipped with large-sized caps, should be located strictly in the center of the specially prepared notch.

Traditional types of finishing

Facing with clinker tiles

Facing with clinker tiles

Before how to repair the facade of a building, you should remember such common types of finishing as tile and porcelain stoneware, which are traditionally used as finishing materials of the facade. A wide range of color shades and sizes of elements of such coatings allows you to choose the most suitable for your conditions finishing option. Taking into account all the above, their choice for finishing the facades of a building can be considered quite justified.

We also note that neither the tile nor the porcelain stoneware does not need additional care, differing at the same time a good ratio of price and quality.Thus, in principle, any owner of private housing can afford the choice of this classic finishing material.

Blockhouse

Blockhouse

Video

See detailed installation instructions for the front panels: