Wooden floor, mounted in an apartment, country house or other premises, is one of the most convenient and environmentally friendly coating options. Among other things, the coating has excellent thermal and sound insulation, which is why it is so widespread in the construction of country houses. The tree is a material which introduces heat and a cosiness to the house. Modern technology allows you to buy a variety of wooden coatings that perfectly mimic expensive woods, such as walnut, oak or mahogany.

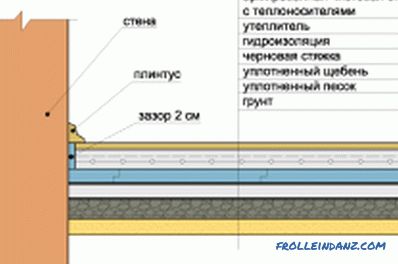

Before laying wooden floors on the ground, you need to consider what the soil is under the floor, if the groundwater level is high, it is imperative to make reliable waterproofing.

As you know, the basement or first floor has a soil base on which you can build only two types of floors: wooden and concrete. Wooden floor on the ground today is quite popular, especially for the basement of a warm country house. As for the concrete pavement, it is better suited for garages, verandas, storage rooms and basements on the street.

The wooden floor on the ground must be laid according to the type of soil present on the plot. There are cases when the level of groundwater is so high that the soil becomes completely wet. In this case, it is necessary to make high-quality waterproofing, without which reliability and integrity of the structure over a long period cannot be guaranteed. Therefore, the first and most important condition of any wooden floor on the ground is dry ground. Laying the wooden floor on the soil, first of all, is very profitable, since it does not require additional costs for the purchase of expensive building materials. Of course, with the acquisition of heat and waterproofing costs increase slightly. But in any case, such a coating on the ground is the most convenient and affordable.

Construction of a wooden floor over the ground

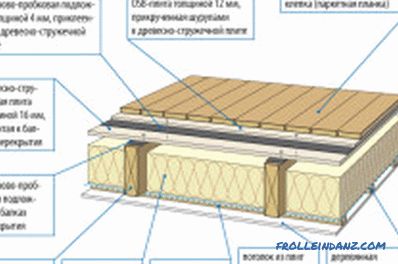

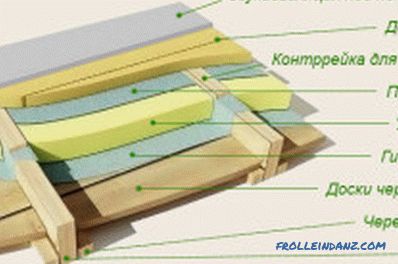

To insulate a wooden floor with mineral wool, you must first make waterproofing on both sides of the thermal insulation material.

There are several differences between ordinary flooring and the floor on the ground. First of all, it is a small layer between the ground and the floor - the ventilated underground. Its height usually ranges from 10 to 20 cm. As it was already possible to understand from the name, such an interlayer is necessary for ventilation, that is, for continuous air circulation. If this height is reduced, then the heat loss associated with impaired circulation will increase.

A brief description of the main stages of laying the floor:

- Prepare the soil foundation - this includes leveling the ground, adding gravel and ramming.

- Pour a layer of so-called lean concrete.

- Make a markup - at this stage it is necessary to install beacons and determine the placement of brick “tables”.

- Lay the concrete screed on the underlying concrete layer under the “tables”. The cabinets themselves must be made of solid brick.

- Lay a double layer of overlaid roofing felt.

- Install floor waterproofing (wet soil) if necessary.

- It is imperative to install wooden pads impregnated with antiseptic.

- In order to warm the floor, it is necessary to pour slags along the external walls of the underground during installation. Often the thickness of the layer can reach one meter.

- Lay the wooden timber on the bedside tables made of bricks.

- Attach floor boards to the logs with nails.

- Next, using a conventional planer, you need to level the wooden floor along the ground.

- The next step is to caulk the surface, especially in those places where the joints of boards and nail heads are located.

Diagram of the installation of support posts under the logs of wooden floors.

Particularly responsible is the need to approach the process of grinding the coating, since the smoothness of the floor will depend on it. Initially, as mentioned above, you need to walk a plane on the floor. Then, using sanding paper (sandpaper), thoroughly sand off and polish the wooden floor. Wood has the peculiarity of being transformed after varnishing (a pronounced structure and color appears), so that after sanding it is recommended to cover the floors with a colorless varnish.

All of the above works can be done independently, if you have on hand a clear step-by-step instructions and all the necessary tools and materials.

Required working tools and materials

To work with a wooden floor on the ground, you will need some working tools and, of course, the necessary materials:

- plane;

- electric jigsaw;

- perforator or jackhammer;

- reciprocating saws;

- vibrating plate or tamping machine;

- screwdriver - preferably with battery;

- electric drill;

- FSF plywood;

- consumables;

- fasteners;

- wooden beams;

- wooden boards;

- steam and water insulation;

- floor insulation;

- impregnation for wood.

Technical features of work stages

As it is known to people who have experience in carrying out installation work, each work stage has its own characteristics. Therefore, compliance with the recommendations on the implementation of these steps will help to perform the work more efficiently and quickly. As for the work in your own home, first of all, attentiveness and patience should prevail in the work.

The floor structure consists of the following: sole, bedding layer, waterproofing, heat insulation, base layer, facing material.

The scheme of insulation of wooden floors on the ground.

Sole - work should always begin with a good and solid foundation. In this case, you need to remove the top layer of soil (about 0.5 m). Instead, you need to fall asleep coarse sand. After falling asleep, it is necessary to well tamp the layer using a vibrating plate or tamping. For improved shrinkage you need to water the sand. This will noticeably improve his sitting position.

Litter layer - it is necessary in order to evenly distribute the pressure over the entire surface of the soil layer. In turn, subsidence in one place may entail the deformation of the entire coating. The most commonly used 5 cm concrete screed. Also modern solution is the laying of the profiled membrane. The cost of work and the time it is completed due to this are significantly reduced.

Waterproofing - necessary in order to protect the structure from moisture ingress. In addition, it protects against pathogenic bacteria such as mold, rot and fungus. Malicious bacteria not only destroy the coating, but also significantly reduce the level of comfort due to dampness and smell. The following materials are used for waterproofing: polyester, bitumen mastic, PVC membrane, fiberglass.

The scheme of insulation of a wooden floor.

Thermal insulation - a large amount of heat always goes through the floor. To prevent heat loss, a heat insulation layer is used, the material of which has a low thermal conductivity. For this fit: expanded clay, polystyrene foam, polyurethane, foam, mineral wool, glass wool. It is necessary to choose thermal insulation first of all proceeding from financial assets and own preferences. With enough money, you can install a warm electric or water floor. The presence of heat in the house will provide for the long term the maximum level of comfort and coziness.

The main carrier is the main component in the overall design. Represents a wooden covering from a certain breed of a tree.

Facing coating - in the event that a wooden covering does not suit you, then it will be possible to put a facing material on top of it, although in practice a wooden covering is the best facing material.

Do-it-yourself installation process: securing the material

As already described above, the construction of a wooden floor over the ground is a warm and primarily ventilated floor. The process of installation itself is the following scheme.

It is imperative that you test the soil for strength (soil preparation). In that case, if its strength is doubtful, you need to remove a small layer of soil and instead fill it with sand mixed with medium rubble. It is recommended to add to the bitumen solution and to pack all the filling well.

Using a construction level, you need to install beacons and determine places for future “bedside tables.” It is recommended to fill a thin layer of concrete screed. After filling with a level, level the entire coating.

It is undesirable to make brick “tables” from silicate bricks and artificial stone. It should also be noted that the installation of "bedside tables" can be started only after the complete drying of the screed. Further, you need to lay a waterproofing and insulation layer.

You can begin installing a bar (lag) over brick bedside tables and a waterproofing layer. Screws. The main thing is to take into account that there should be a free space of 2 - 3 cm between the walls and the lags.

After that, floor boards are being laid. The boards should fit as closely as possible to each other Used for this wooden pads. Finish work by grinding and polishing the coating.At the same time, the true texture will appear immediately (especially if it is a tree of noble species).

Didn't find the answer in the article? More information on the topic: