The steel pipe profile belongs to the category of the most attractive materials used in the construction of structures of various categories. The special attractiveness of the profile blanks is associated with the presence of many remarkable properties, the main of which are the simplicity of the preparation of pipes, the ease of their molding and installation.

This explains the high demand for specialized products among private traders who are planning to assemble a house frame from a shaped pipe with their own hands.

At the initial stage of assembly work, you should decide on the optimal parameters of the profile blanks (their section and total number), ensuring the strength and reliability of the future frame. After that, it is necessary to designate those construction sites for the construction of which pipe metal profiles will be used. It should be noted that the following metal pipes can be assembled from:

- the base of the trim and the floor;

- the outer walls of the frame;

- the interior partitions;

- overlapping base and roof.

Preparing for installation

Mount the frame of the house

Mount the frame of the house

For self-sufficient preparation of the frame structure of the profile, you can use standard kits coming into the free market. In this case, its installation is reduced to simple assembly operations performed using classic screw connections.

In the event that you decide to use separate profile blanks for installation, you will have to recruit a welding specialist to work and prepare a complete set of relevant equipment. In this case, the assembly of the composite metal structure is carried out, as a rule, directly on the site of the construction of the future structure.

When installing a frame structure, it is necessary to strictly observe all the requirements of the assembly instructions, paying particular attention to the quality of welding of individual components.

Vertical and horizontal installation of all elements should be monitored, as well as the correctness of their placement during assembly.

Since the mass of the metal prefabricated structure is small, ordinary piles or reinforced concrete blocks of small size can be used as the foundation.

The order of installation of the structure

The frame is assembled from a shaped pipe usually in this order:

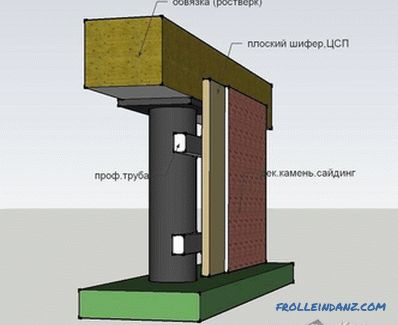

- First of all, the lower strapping is prepared, the elements of which are welded reliably to the foundation tabs (pins). Such an attachment gives the erected structure the necessary stability and rigidity.

- Then the corner posts of the frame are welded to the elements of the bottom trim.

- Intermediate vertical posts are mounted along the perimeter of the structure at an equal distance from one another (equal to or slightly less than the width of the cladding material).

- After that you can proceed to the final fastening of the posts by welding the top trim to them. In order to impart additional stability to the structure, it is recommended to use special spacers made from the same profiles and welded to the trim elements.

Pipes with a wall thickness of 8 mm and a cross section of 100x100 mm are usually used for assembling frame elements that experience an increased load effect (lower piping and pillars). Additional spacers are made of profile section 60x60 mm.

Special attention should be paid to the profile logs on which the subfloor is laid and which are fixed on the bottom trim beams by welding.

To get a full-fledged floor covering, the distance between the laid lags should not be more than 60cm.

Upon completion, you can proceed to the installation of a floor slab. This frame construction includes a set of special profiles fixed on the walls of the erected structure and floor beams, to which the ceiling paneling is attached from below.

Assembling of the roof elements

Truss from a profile pipe

Truss from a profile pipe

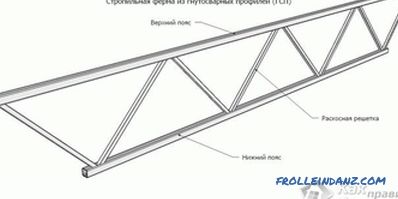

At the final stage of preparing the frame of a house, the roof system of the structure is assembled with its own hands, which can be part of the whole structure or be a separate structure.

In the event that you use light materials (polycarbonate, ondulin or transparent slate) to close the roof, it is most convenient to assemble lightweight structural elements on the ground. Farms prepared in this way can then be lifted up and welded to the strapping elements. To prepare the roof of heavy materials will need to use more powerful profiles. In this case, the assembly of the structure is best carried out directly on the roof.

As the main carrier element of the roof, the mauerlat, a powerful channel is used, to which all other elements of the roof are subsequently fastened (runs, rafters, ridge supports, etc.).