There are certain things that talk about high status or create comfort. One of the building materials that boasts such qualities is wood. A wooden ceiling with your own hands is not only an opportunity to create a unique interior, but also a chance to improve skills in decoration. There are some nuances in the installation, as well as the positive and negative sides, which should be weighed before proceeding with the installation work.

Main nuances

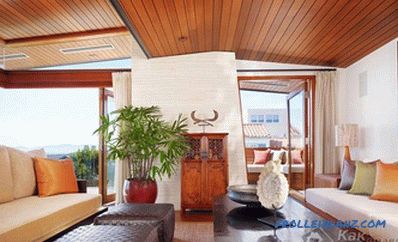

A real decoration

A real decoration

The ceiling should create a feeling of lightness, and do not clutter the space. This effect can be achieved by correct selection of colors, textures, as well as shapes. Wood is a very flexible material in processing, it can be given any shape that the master wishes. Such solutions have many advantages:

- The natural basis is always highly ecological. You can not worry about allergic reactions or unpleasant odor. With the right approach, you can use water-based dyes.

- The durability of wood is difficult to overestimate. If you provide good care and stay on hardwood, the ceilings will last so long that they can get bored.

- Compatibility with any interior. This type of material is suitable for both antique finish and modern style.

- Excellent insulating properties. This applies to both sound and heat loss. That tree was the main material for construction in ancient times, because people were well aware of such positive qualities.

- Creating a unique solution. You can order a ceiling project from an experienced joiner.

Wooden ceiling in the loft style

Wooden ceiling in the loft style

There are some dangers to consider:

- Love by pests. If this is a solution of pure wood, and not of slabs, then it is imperative to ensure good treatment with antiseptic compounds.

- Need for proper storage. In the case where the wood was stored incorrectly, this may lead to the fact that the already finished structure will begin to crack and lose its appearance.

- Possibility of ignition. It is important to think about this moment well in order to avoid accidents later.

- Relatively high cost.

Types of wooden ceilings

It will be difficult within a single article to list all possible solutions that exist. There are several basic ones, but this does not mean that fantasy should be limited to any framework.

From a cut board

From a cut board

From a cut board. In this case, the usual inexpensive building material is used. Appearance is given to it at the request of the customer. In some cases, the surface is fired with a gas burner, ground and varnished.

Beams from a chipped log

Beams from a chipped log

From a chipped log. It is more correct to say from the cut. They are based on rounded parts, which are fixed to the base with a flat side. In this case, only bark removal and polishing are carried out from the treatment, after which the elements are covered with stain or varnish.

Ceiling from lining

Ceiling from lining

From lining. At its core, this is the same edged board, but well-polished. It also made grooves that provide simplicity and ease of connection between them.

Out of eurolining. Equivalent to the previous solution, but finishing is much better. In addition, the wood has already given a certain shade. Also on the seamy side a special notch was made, which contributes to the ventilation of the whole structure. Sizes exactly match the stated. No need for additional impregnation.

Coffered wooden ceilings

Coffered wooden ceilings

Coffered. The word came from French. In translation, it means "box". This solution was often used in ancient times. It was rather forced constructive than decorative. Such a decoration was obtained due to the crossing of the beams. Nowadays, this type of ceiling has received a new birth.

Blockhouse

Blockhouse

Blockhouse ceiling

Blockhouse ceiling

From the block house. If you combine chipped logs and lining technology, then just get a block house. On the front side, it has a convex semicircular structure that resembles a rounded log. The slats provide grooves and spikes that facilitate installation. After all the work is completed, a surface is obtained that resembles a good old hut from a log house.

Plywood ceiling

Plywood ceiling

Plywood. In this case, the ceilings are quite even, but further painting and varnishing will be mandatory, since without such a decoration the appearance will not be attractive enough.

From MDF

From MDF

From MDF panels. The material is very similar to wooden paneling, but the structure has a structure as well as a special film that eliminates the possibility of mechanical damage.

From decorative panels. In this case, an individual project is compiled. Next, the panels are made of the desired shape. This type of finish is one of the most expensive. In some cases, an array is used in which the patterns are cut out.

Of the fillets

Of the fillets

Of the fillets. These are wooden cornices of a small width. Unique patterns are made on them. You can arrange them in the correct geometric forms to create a solid appearance.

Wooden Wallpapers on the ceiling

Wooden Wallpapers on the ceiling

Wooden wallpaper. In fact, veneer is applied on a special base. After gluing such material, the impression of a monolithic ceiling, which is decorated with expensive material, is created. In addition, this view will be relevant if the surface of the ceiling is made in the form of an arch. The thin layer bends easily and takes the form of a structure.

In other ways of realization, the plane itself can be from any material, for example, from gypsum cardboard, but with wooden beams. In this case, it turns out to reduce costs and get the desired result.

Natural wood requires that at least once in 3–5 years the applied varnish or other coating be replaced. Due to this, inside it will not rot and dry.

Where the wooden ceiling is particularly appropriate

Chalet-style interior

Chalet-style interior

There are certain interior or exterior solutions where wood ceilings are not only desirable but necessary.

- Chalets. This concept is borrowed from the Swiss. In the original sense, this is a small rural house or a hunter's hut. For this style is characterized by a large number of beams.

- Country. When we hear this word, then, most likely, music with the characteristic sound of fiddle begins to play in the head immediately. In the interior design it is expressed in rounded ceiling beams, wooden walls. For such a solution is usually used a block house or a round log.

- House or bath from a felling. In this case, there is not much to say. The building itself requires just such a finish.

Country style interior

Country style interior

To combine the wooden ceiling with other modern ones materials of the walls and floor, it is worth to pick up solutions to match or provide some island wood inserts on these surfaces.

Preparatory work

Waterproofing the ceiling

Waterproofing the ceiling

- First It is necessary to calculate how much material will be needed for the surface. To do this, you need to multiply the width of the ceiling by its length and add another 10% to the result. This stock will be needed when performing trimming or damage to one of the blanks.

- When making a purchase, ask the seller to show the conditions under which the storage took place; this will avoid problems that may appear after installation.

- Installation work should take place at a temperature not lower than + 15 °. Also, the board must lie down for several days in the room in order to acquire the internal humidity of the room.

- If required, it is necessary to make additional treatment with antiseptic, as well as fire retardant coating.

- All layers of the old finish are completely removed to eliminate possible harmful interactions.

- If the surface is concrete, then it is covered with a primer in order to further strengthen it and eliminate sprinkling. It is useful to apply a layer of antiseptic composition.

- Wood is very sensitive to moisture, so you need to stretch the waterproofing. This may be a special membrane that is used in construction. It is fastened to beams with a stapler, and to a concrete base with dowels and screws or umbrellas. Between the individual layers need to provide overlap of 10 cm and seams glue tape.

- At this stage it is also important to check the ceiling plane. This can be done with, for example, a water level. On one of the walls at an arbitrary height marked. Further it is necessary to transfer it to other planes. To do this, one part of the level is attached to the label, and the second to the required place, after which you need to wait a little for the liquid inside to even out. From each line you need to measure the distance to the ceiling. Thanks to this, it will be possible to find out the differences and take them into account when fastening the bars of the sheathing.

- For more convenience, you can pre-mark the crate.

Manufacturing of lathing

Lathing for fastening lining

Lathing for fastening lining

Basis for cladding is better to make of wood.The use of the metal version will be relevant in the event that the material you have left after previous work. You will need a board with a thickness of 25–30 mm and a width of 50 mm (it will not be a problem if the width is larger, this, on the contrary, will provide better fit and fixation).

- Installation must begin at the angle where the deviation from the level is the smallest. Thus, it will be easier to set the crate in a horizontal plane.

- The lines should be located perpendicular to the joints of the material that will be attached later.

- The step between the individual elements can be within 3050 cm.

- The boards can be fixed to the wooden surface simply with screws, to concrete with dowels and screws. At the same time, in the places where the junction will be made, it is better to pre-drill a hole slightly smaller than the diameter of the fastening material. This will eliminate the splitting of the bar, as well as simplify the twisting.

- During installation, it is important to use the building level to maintain the plane.

- To make the work go faster, you can fix two strips in opposite parts of the ceiling, stretch the line between them and it will serve as the required level along which the rest of the strips will be set.

- At this stage all the necessary electrical wiring is also laid. It is better if it is hidden in a metal corrugation, then even if a short circuit or other unpleasant situation occurs, the insulation will not cause a fire.

Wiring

Wiring

It is necessary to ensure that the boards for the batten are not infected with pest. In any case, they should also be treated with antiseptic, so they will not cause damage to the entire structure.

Installation work

Cladding with clapboard

Cladding with clapboard

Installation of such materials as lining, block house and MDF panels will be very similar in principle.

- A total width is measured and divided by the width of one slat. So it will be possible to know how many parts will go. In addition, it will make it possible to determine whether the first and the last elements should be trimmed to maintain symmetry, and what size it should be done.

- A 10 mm indent is made from the wall. He will perform the role of a thermosca. Thanks to him, the material will be where to move when expanding. If this is a house that is built from a log house, and its full shrinkage is not over yet, then this gap should be increased to 20 mm.

- The spike is cut off on the first bar. This part of the element turns to the wall so that the groove is in the course of advancing the finish.

-

Fastening the lining In order to fix it to the crate, clamps with teeth are driven into the end face, or the screw is twisted at an angle. It is better to first profit and put it on the level. If this is not done, then all subsequent elements will fall with an offset, which will lead to the fact that the joint lines will not be parallel to the walls.

Fastening the lining In order to fix it to the crate, clamps with teeth are driven into the end face, or the screw is twisted at an angle. It is better to first profit and put it on the level. If this is not done, then all subsequent elements will fall with an offset, which will lead to the fact that the joint lines will not be parallel to the walls. - The next element is inserted with a spike into the groove of the previous one. To drown it well, use a rubber mallet or an ordinary hammer. But in the second case, the blows must be made through a wooden lining, so as not to damage the locking mechanism and not to leave dents.

- The ceiling does not experience such a load as the floor, so the facing can be placed joint to the joint without the need for binding seams. But it is better to use the layout - this is a special docking plate, which will hide the shortcomings of the ends.

- In the course of installation, the cables that were previously laid are removed.

- After the surface is ready. The facing material of wood is again covered with antiseptic composition. This indication does not apply to MDF panels.

- Next, apply a primer. After that, the surface is polished with fine sandpaper and varnished in 3 layers. One should go along the fibers, the second one perpendicularly, the third one again along the fibers. After the first two layers, it is also better to go through fine sandpaper to improve adhesion.

- All gaps that were left up to the walls are covered with decorative plinths.

Plank covers joints

Plank covers joints

The plywood ceiling is laid on the same crate . Before this, it is necessary to cut the sheets into identical squares and then assemble them. All joints and places where the screws will enter are closed with putty on wood. The next step is to cover the entire surface with stain and varnish. This decision will come in handy when it is necessary to align the plane.

The following video shows how to clapboard the ceiling:

Insulation and sound insulation

Insulation ceiling

Insulation ceiling

If there is a desire to provide additional sound and heat insulation, then for the batten you will need to choose boards of greater thickness, for example, 5 cm.By the size of the space between the battens of the batten, expanded polystyrene is cut. The width should be chosen so that it comes in tightly. It must be inserted during the installation of the slats in order to immediately fix it. As an option, you can use mineral wool, but in this case, from above it will again need to be closed with oilcloth, so that over time its fibers do not start to fall out through the cracks.

Coffered ceiling

Installing the coffered ceiling

Installing the coffered ceiling

This type of project will require you sufficient mental effort, as well as exposure during installation. Regarding the conditions of its installation, there are restrictions on the height of the ceilings - they must be at least 2.5 m. Otherwise, their level will drop so much that it will be uncomfortable inside.

- On a sheet of paper, draw a rectangle in proportions that will correspond to the ceiling.

- A drawing of the desired structure is made inside the outline. All patterns, junction points and dimensions are thought out.

- Surface preparation is performed as described above, but the crate is not mounted. If the level drop is too large, then it is additionally necessary to perform leveling with a putty. After complete drying, it must be primed.

- The whole plane is covered with wallpaper. It is better if they are without a pattern, in one tone, a small structure is allowed. To make them well, you need to smooth them with a plastic spatula from the middle to the edges. If desired, you can provide the effect of confusion. You do not need to align the canvas too much.

- Using chockline and guided by the drawing, apply the markup for the future construction.

- False flippers are made. They are a wooden chute. Usually, such wood species as oak, larch, aspen, etc. are used for this. Blanks for them are selected in accordance with the height of the elements you have chosen. Additionally, they can be aged with a special brush on wood, as well as coated with stain and varnish.

- Next, they are mounted to the ceiling. They can hold, for example, on brackets for metal profiles. They are bent and fastened to the wall. Curved ends are placed inside the false head. Next is the fixation with screws. In this case, the head must be drowned flush and then closed with a putty on the tree, which will be suitable in color.

- At first, all longitudinal elements can be fastened and then jumpers.

The whole matter will be simplified if there are already beams on the ceiling that are part of the structure. Then it is necessary to make jumpers from the same material or with the help of fals, so that squares or rectangles are formed. Next is the finish painting.

Polyurethane plinth or fillets can be glued to the inner corners, which will give a special zest to the whole project.

Wooden ceiling in the bath

Hemmed wooden ceiling in the bath - cake

Hemmed wooden ceiling in the bath - cake

Usually the ceiling in the bath is made by the method of filing. For it, you can use wooden wall paneling or block house. The main difference from the usual design will be the presence of a barrier not in the form of a membrane, but in the form of a dense construction foil. It must also be attached overlap. Such a substrate is made so that the condensate formed can calmly drain without accumulating and not causing the wood to rot. Also in the steam rooms, it is desirable to use stone mineral wool for insulation, it is well tolerated by high temperatures and does not burn.

Wooden wallpaper

Veneer

Veneer

This is a very interesting design novelty. Such wallpapers can be both profiled and even. There are several main types:

- Plates. Planks from solid wood are interconnected in square or rectangular elements, which are then mounted on the surface. Their thickness, as a rule, does not exceed 2 cm. In appearance, such a product resembles clapboard, but the strips are much smaller.

- Thermally treated. The principle of manufacture resembles the production of chipboard. At the same time, wallpapers acquire greater rigidity and resistance to various influences, including moisture.

- Based on cork. Can be produced in rolls or as individual tiles. Represent a layer of cork, which is glued to the paper base. From above it is covered with a special varnish, which protects them from moisture, absorption of odors and other effects. Their thickness can reach 3 mm.

- Based on veneer. In this case, the thickness of the wallpaper can also reach 3 mm. Thin sheets of wood are applied on a paper base, and on top are covered with protective varnishes. Additionally, engraving may be applied.

Using this solution allows you to hide most of the flaws and irregularities that a ceiling may have.If you plan to use tile material, then it will be attached in the same way as the wall paneling.

Wooden wallpaper - slats

Wooden wallpaper - slats

For cork slats, as well as products in rolls, it is necessary to prepare the ceiling without installing crates. Further, the sequence of actions is as follows:

- The marking and cutting into strips of the required size are performed.

- After that, they must be left at least for one day in the room so that they acclimatize.

- When working, it is desirable to close all the doors so that there are no drafts, and also to prevent the ingress of direct sunlight.

- The surface of the ceiling is covered with an adhesive. They are also covered with wallpaper. Do it better with a roller.

- Next, the segments are applied to the ceiling and are well pressed. This will be easier to accomplish with a second rubber roller, which will remove air residue.

- If the glue has penetrated through the seam, then it must be removed as soon as possible with a damp cloth.

Cork slabs are also glued to the ceiling. At the same time, work should be started from the middle and move to the edges, then the main territory will be filled with whole parts, and all trimming will go to the edges.

Now you know how to make a wooden ceiling or imitate it yourself. Each of the methods can be combined with each other. For example, inside the niches of the coffered ceiling you can glue tiles from cork, which will look very attractive. Good luck in your endeavors!

Video

Below you can see the step-by-step production of the coffered ceiling:

Photo

Unedged

Unedged

Rack Ceiling

Rack Ceiling

Board covered with wood stain

Board covered with wood stain

Caisson MDF

Caisson MDF

Untreated

Untreated

Rack Pattern

Rack Pattern

Mounting of the Boards

Mounting of the Boards

Large beams

Large beams

Wooden hanging

Wooden hanging