Despite the simplicity of this device, if you decide how to choose a glue gun, you will have to face the need to decide on a sufficiently large number of characteristics that you want to pay attention to. At a minimum, this is the power of the device, on which it depends on what components it can work and its performance. If you use the gun for professional purposes, the type of power that comes with the nozzles, the glue readiness indicator, the quality of the stand and other equally important points will be important.

How can you use the glue gun

The prototype of modern glue guns was invented by Harry Green, who at one time set himself the goal of making a tool for quickly gluing furniture parts. His device was rather bulky, he used liquid glue for work, but the technology of its application, which allows to get a neat and even seam, characterized by great mechanical strength and elasticity, became a real breakthrough.

When it became possible to use solid adhesive rods and the heat gun became quite compact, it became very common. It is much easier to list the cases in which it can not be used - it is fastening parts that heat up during operation and can soften the adhesive bond. Also, the glue seizes poorly on concrete, plaster and some types of polyethylene - since the latter are sensitive to heat, some skill is needed to work with them.

Otherwise, the use of the thermal pistol is practically unlimited: the furniture makers were the very first to appreciate its capabilities, the builders glued them the details of communications, and for modellers, designers, radio amateurs, florists and designers, it became a real find. In addition to the almost instant gluing of parts, using a thermogun it is possible to obtain polyurethane shapes or patterns, create paintings or make prints on postcards or invitations.

As a result, a heat gun is essentially the same all-purpose adhesive, but without a strong odor and capable of completely hardening within 1-3 minutes, gluing wood, paper, and cardboard together , leather, fabrics, plastics, rubber, metals, ceramic parts in various combinations. Also, do not forget about the basic rule of application of any glue - the surface must be cleaned and degreased before using it.

Device and principle of operation of the glue thermogun

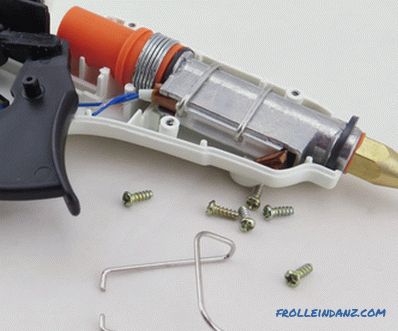

The simpler the design of a device, the more reliable it is considered. Thermoguns fully comply with this rule - inside they have a minimum of components that are highly reliable and, when used correctly, are maximally protected from possible damage.

The form of a hot pistol fully justifies its name - it has a handle for which it is held during operation and the barrel in which the main elements of the device are placed.

In the place where a trigger has a trigger on an ordinary pistol, there is a receiving opening for glue sticks in a thermogun. When they are inserted into the case, they are further approached through the coupling into the melting chamber, to which the heating element (TEH) is attached. The part of the rod that falls here is melted to a fluid state, and if you continue to feed a solid part of it into the chamber, an excessive pressure is created, which pushes the hot melted glue out through the nozzle, which is attached to the “barrel” of the thermogun.

Structurally, the thermogun consists of the following elements:

1 . Glue stick.

2 . Feeder.

3 . Guide Clutch.

4 . Power cord.

5 . Trigger.

6 . Heating chamber

7 . Nozzle.

Case

It performs two functions at once: it holds all the parts of the gun together and is itself a stand to leave the gun in the desired position until it is used. The fact is that when the adhesive mass in the heating chamber is already melted, then the gun is undesirable for a long time to keep the spout up. It is also strongly not recommended to lay it on its side when it is turned on, since this can cause a significant overheating of the body and the exit of the thermal pistol.

To leave the gun in the desired position, a special pad is usually made at the bottom of its handle, on which it is placed, and in front of the barrel there is a folding support made of plastic or steel wire. Thus, the case has three points of support for securely fixing the device in the desired position (one in the handle and two on the stand).

As there are parts inside the device that become very hot during operation, the casing is made of hard plastic with low thermal conductivity.Also, these materials have a low weight, so the total weight of the device rarely exceeds 300 grams.

The thermo-pistol handle usually doesn’t stand out in particular - often there’s nothing inside the power supply and the trigger wire that passes through it. For ease of use thermogun, outside it can be fixed anti-slip rubber pads.

Feed mechanism

A so-called ring pusher is directly in contact with the glue stick - this is a plastic / metal smooth (or with a tooth clinging to the stick) ring. When a lever is transmitted to it, the ring rotates somewhat in a vertical plane, thanks to which the rod is captured and pulled after it towards the heating chamber.

A force is created by a carousel or slider-type trigger (moves around its axis or along the trunk), and is transmitted to the ring by means of a lever. Often, the last part is the weakest point in the mechanics of the device, because inexperienced users can press the trigger too hard, trying to "squeeze" more glue.

When you decide which glue gun to choose, be sure to take into account that the ring itself can be a problem part if it is made for a specific rod size. As a result, even with small diameter errors, the rod will hardly pass through the ring or slip in it.

Guide sleeve

In essence, this is just a rubber tube, one end of which is put on the heating chamber, and the glue stick is put on the other.

This part has two main functions:

- It also wraps around a hard rod that prevents the melted mass from flowing out of the heat chamber into the gun body.

- It is a kind of temperature bridge - if the glue rod would be brought into the heat chamber right away, it would have melted before it due to heat transfer due to heat transfer.

Despite the fact that the guide sleeve is made of heat-resistant rubber, it should be remembered that this is one of the weakest parts of the gun. If the whole mechanism even slightly overheats, then the clutch is easily damaged by attempts to turn the rod or simply pull it out in the opposite direction.

If different rods are used, to replace them, it is better to cut off the part that has already entered the sleeve, insert a new rod, and squeeze the previous ones through the nozzle in the usual way.

Heating chamber

In essence, this is a metal tube with a heating element attached to it. Different variations of this node are used in different devices, for example, they install several heaters, which heat the rod not in one place, but gradually from the beginning of the tube to the outlet.

The power and performance of the entire heat gun depend on the heating unit. The larger the volume of the heating chamber, the wider the section of the rod that will warm up, and how quickly this will happen - depends on the power of the heating element.

Despite the fact that this is the main working part, it is often the most reliable - with the proper operation of the device, the heater breaks almost never happen.

Nozzle (nozzle or nozzle)

The main task of this part is to give the desired shape of the adhesive mass out of the nozzle and its dosage. Depending on the class and cost of the thermogun, a direct-flow or with a valve is used. In the first case, it simply provides the necessary thickness of the outgoing adhesive mass, and its dosage is performed by the feeder. The disadvantage of this solution is some loss of glue, since when it reaches a certain level of fluidity, it freely flows out.

If the nozzle is with a valve, then a spring-loaded ball is placed inside it, which blocks the glue mass outlet until the trigger creates excessive pressure to unlock the channel. As an additional protective measure, the ball never completely blocks the outlet orifice - if the working chamber overheats and the glue becomes too fluid, then its surplus is also brought out.

As a result, when working with a glue gun, you should always use a stand on which excess glue will be collected.

Like the heating chamber, the nozzle is made of metal, but outside it is covered with a protective casing, which prevents possible burns if you touch it carelessly. If the nozzle is removable, the heat gun is completed with several such nozzles - this allows you to get an adhesive layer of various shapes. Also included may be additional standard nozzles, but with an elongated spout, which simplifies access to hard-to-reach places.

Fastening to the gun is carried out with a threaded connection, but the old nozzle can be unscrewed only when the heat chamber is already heated - otherwise the part that has been stuck inside will interfere with the replacement of the part.

Technical specifications that need to be considered when choosing a thermogun

Not always "more" means "better" - this fully applies to thermoguns, because such devices are made to perform various tasks therefore, they can be equipped with functions or have characteristics that, if chosen incorrectly, will remain unclaimed.

Power and heating rate

The heat gun power means the number of watts per hour that the heating device consumes. It is easy to assume that the higher this characteristic is, the less time will be spent on melting the glue, but it will also be helpful to take into account such concepts as efficiency and productivity. For example, a combination of a roomy heating chamber and a weaker heater, which can still provide the right temperature, will consume less electricity than a powerful heater and a small chamber. In addition, the risk of overheating is reduced, which affects the overall service life of the device.

For comparison, professional devices consume about 300 watts per hour, but they are designed for rods up to 45 mm in diameter. For work with rods of 7-11 mm, heating elements of 30-150 W / h are used.

It may happen that the power of the device is not enough - then when the current supply of glue is used up, you will have to wait until the new melts in the chamber.

Some manufacturers went ahead and supplied the heating chamber with a temperature sensor, which allows automatic power control to be obtained. When the camera is cold (before switching on), the consumption will be maximum - about 200 watts, and when the optimum temperature is reached, the standard or economy mode is activated, in which heating elements require 15-40 watts.

As a result - if it is not critical in 3 or 5 minutes the heat gun heats up to working condition, then there is not much point in pursuing a more powerful device. If it is supposed to work with him for many hours, then deciding how to choose a glue thermogun, one should pay attention not to power, but to its performance. If for some reason the heating rate is important, then it is better to purchase a device with a power regulator.

Melt temperature

Since the heat gun is used to work with a large amount of materials, it should be noted that they all transfer heat differently and for some you need glue with less (if possible) melting point. For example, for paper and many types of fabrics used pistols operating at a temperature of about 105 degrees. Also manufactured devices that can operate in several modes, usually it is 105 165 and 200 degrees.

It is clear that the higher the temperature in the chamber, the lower the durability of the device itself. Also here we must take into account that the vast majority of glue rods melt already at 105 degrees, and the heat chamber, which produces a higher temperature, simply accelerates the entire process of work.

As a result, if a heat gun is purchased not for professional use, there is no sense in choosing models with a maximum temperature. The golden mean for this characteristic are values of 165-170 degrees. If you choose a professional device, you should pay attention to models with a temperature controller, which can be manual or automatic - the control is made by the chip, based on data from the sensors.

Thermal Pistol Performance

This characteristic is also called the pistol speed, although it is more correct to speak about its performance. This is one of the main values that are recommended to pay attention when choosing a thermogun - it shows the amount of glue that can be squeezed out of the nozzle for a certain time. For different devices, this value will vary from 5 to 30 grams per minute and is usually indicated in the device passport.

In parallel with the performance of the gun, you need to pay attention to such a parameter as the flow time of the adhesive, especially if you have to work with large areas of bonded materials. Otherwise, the glue at the beginning of the seam may harden before it is applied at the end.

Accordingly, it is by the performance of the device that they are divided into professional and household ones, because if the heat gun is used for small crafts, this parameter will have no meaning.

Type of power source

If most electrical devices can be operated from the mains or independently, then the thermo-pistols in this regard can boast even three modifications:

1. From the network .The most common standard design with power cord.

2. On battery . Such devices allow you to work independently from 45 minutes to 2 hours. At the same time, the characteristics of thermo-pistols are quite good - they can heat a rod with a diameter of 7 millimeters to almost 200 degrees in 15 seconds.

3. Semi-Autonomous . A device with such a design has detachable power cord after which the temperature in the chamber is maintained for 10-15 minutes.

Wireless devices are also common, which is used in tandem with the docking station - while the gun is in it, the heating chamber is heated. An additional advantage of the docking stations is that they have a container for collecting glue that is gradually dripping from the nozzle.

Diameter and length of the glue rod

Standard and semi-professional devices are most often designed for rods with a diameter of 7 and 11 mm. In this case, manufacturers take into account possible errors and in the characteristics of the device indicate not the exact value but its range - usually it is 7-8 and 11-12 mm.

Professional devices that are used in industrial production and are designed to produce a large amount of glue per unit of time, use rods of larger diameter - up to 45 millimeters.

Some manufacturers produce rods and pistols for them oval-shaped - they do not have any differences in operation, but choosing such a device it is advisable to clarify the possibility of purchasing consumables for them in the future.

The length of the rods can vary from 4 to 20 centimeters, but since cooling and warming is not critical for them, it is allowed to charge the long rod and use the heat gun with interruptions until it is completely consumed.

The rods are also different in color - blue, yellow, black or with sparkles. In addition to decorative applications, manufacturers can thus mark rods for various applications. For example, rods are often painted yellow for bonding glass, and black for sealing joints.

It should be borne in mind that there are no uniform standards yet, so every manufacturer is free to paint the rods as he sees fit. Therefore, it is not necessary to focus only on the color and when buying, be sure to ask the seller about the purpose of the adhesive or ask for instructions.

As a result, how to choose the glue thermogun correctly and for which rods it completely depends on the purpose of its acquisition. For small crafts, a device designed for rods is 7-8 millimeters, and if more productive work is planned, then 11-12. If it is not expected that the rod will be replaced frequently (for example, for work with materials designed for a different temperature), then special attention should be paid to their length.

Feed mechanism

Here the main difference is in the presence / absence of the trigger or in the design itself of the latter. If there is no trigger for the thermogun, then the rod will have to be fed into the heating chamber manually - this is an inconvenient and ineffective system that is practically not used, but is still found in budget models. This design has only one advantage - there is no risk to break the transport mechanism. This is also a disadvantage, because manually pushing the rod into the heating chamber increases the risk of damaging the guide sleeve, which in most cases leads to damage to the entire device.

If the trigger is present, it can be swivel or drawl - in the first case it resembles a sector of a circle, and in the second case a rectangle. It is much easier to use a swivel - less effort must be applied to it, and the dosage of the adhesive is more accurate.

The rotary trigger.

Pulling the trigger.

The presence of nozzles

Here the choice is very simple - removable nozzles are always better than one built-in, and the larger their number, the more functional the tool will be.

At the same time, depending on the intended front of work, it does not hurt to pay attention to the shape of the nozzles - it is not always round - flat nozzles are periodically caught, which can lay out the glue in the form of a track .

It is also worth examining the quality of the thread so that the nozzles twist / unscrew without interference, as well as the key for which the splines are sharpened. Sometimes there is not enough space for them and it is very inconvenient to unscrew them with a standard wrench, and the use of pliers can damage the protective coating.

Additional options for comfortable work

If the technical characteristics of the device determine the quality of its operation, then there are a number of additional options directly affecting the comfort of using the device. It will not be out of place to look at them, especially if the thermogun is purchased for regular use.

The presence of a temperature controller . Determines the versatility of the device, which can be used to work with a large number of materials.

Electronic automatic temperature control . The prerequisites for the introduction of this function was the negative experience of users of conventional devices, who noticed that if they were not disconnected from the network during interruptions, then the thermal pistols are much more likely to break due to overheating. Now the electronics switches the device between three modes of operation: warming up, operating temperature and lower power consumption in standby mode.

Readiness display . When the heating chamber picks up the calculated temperature, the LED on the thermogun body lights up. The function extends the service life of the device as the user does not attempt to squeeze out the not yet melted glue from the gun, exerting excessive efforts on the feeder.

Highlighting . One of those options, about which you do not know exactly when it will come in handy, but sooner or later its presence is very helpful.

Viewing window . Present in almost all models - budget and expensive. It is useful in cases when it is necessary to replace a long rod or to check how short it goes into the thermoblock so as not to damage the coupling.

Stand . Since in the standby mode, the thermogun should be nozzle down, the presence of a folding stand is considered mandatory. Another thing is that not in all models this part provides sufficient stability of the device, so it is advisable to pay attention to it when buying.

Options . It all depends on the manufacturer, who can offer along with the device a branded case, a set of rods for various needs, as well as a heat-resistant mat, from which it is easiest to clean the glue that drips from the nozzle.

Since the heat gun is a fairly simple device, in fact, not much more difficult than a soldering iron, with proper operation, even a budget model can last for a very long time, even if this device is not a well-known brand. However, even branded devices with protective electronics and other "buns" are quite inexpensive - you just have to choose which glue gun will be better for your needs.