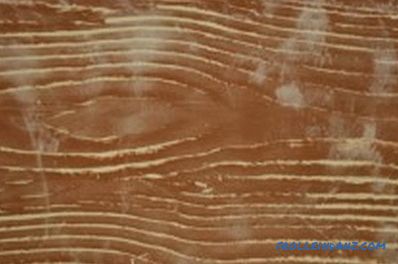

The tree has always been and will be in demand, because it is a natural, living material and no new-fashioned plastics can compete with it in creating an atmosphere of warmth, goodness and comfort in the room. But like any living material, wood products require care and protection. For this purpose, special varnishes and stains are widely used.

Varnishes and stains protect wooden products from dirt and scratches, and also protect the wood from moisture penetration.

Treating wood with these means not only protects it from excess moisture, exposure to light, dirt, scratches and other adverse factors, but also adds sophistication and nobility, fixing and emphasizing the natural beauty of the treated wood pattern.

Removing an old coating

You should always apply varnish on a clean surface. If this is a new product, then no problems arise. But there are often cases when it is necessary to lacquer an already painted wood, for example window frames, doors or wooden floors, the surface of which is damaged due to prolonged use. And if the integrity of the coating is violated, then its protection is violated. Therefore, before embarking on a new treatment, it is necessary to completely clean the surface of the layer of old varnish.

There are three main ways of cleaning wooden surfaces from the old coating: washing with special solvents, thermal or mechanical action. To determine which method is better to apply, it is necessary in each case individually, based on the type of product and the materials used to cover it.

The surface of the product is moistened with a solvent, then removed with a spatula.

In the first method, the old varnish is removed with the help of special liquid solutions, with which the entire surface of the product is wetted with a paintbrush. Immediately after treatment, the product should be covered or wrapped with plastic wrap to create a thermos effect. After 24 hours, the film is removed and the old coating is carefully removed with a spatula. If the coating is removed poorly, the whole procedure is repeated anew, and so on until the wooden surface is completely cleaned.

When working with solvents, it is important to remember that they include toxic substances. Therefore, they must be applied with glasses, rubber gloves and a respirator. At the end of the cleaning, the tree is rubbed with warm water and allowed to dry for at least 24 hours. After that, the surface is ground again and ground. And only after that you can apply a new varnish.

In the second method, to remove the old coating, the wood is heated. In this case, the varnish softens and is easy to remove with a spatula. Heated with a building dryer, you can use a blowtorch. But working with it is more difficult, because you need to constantly monitor that the tree does not overheat and does not catch fire. To protect it, it is better to pre-moisten with water and only then handle.

The latter method is more often used if you need to remove an old layer of lacquer from a large area, for example a floor or a wooden terrace. Remove it with a grinder, and the remaining paint is removed with sandpaper.

Surface preparation

All the gaps on the wooden surface should be carefully puttied and sanded.

Varnish can only be applied on a sanded smooth surface. Regardless of whether the new material needs to be painted with varnish or old, it should be carefully examined. All detected seams, cracks and knots should be processed and eliminated.

Found gaps between the seams and joints need to be sealed with a special putty. After applying the putty, it is allowed to dry, and then, to remove possible irregularities, the puttied areas are re-polished with fine emery paper.

It is also necessary to take into account the fact that a raw or even underdone tree is meaningless to putty, and even more so to process linseed oil, stain or varnish.

Drying, the tree is deformed, and the applied layer will inevitably be damaged.

Peculiarities of using wood stain

The stain should be applied parallel to the wood fibers, avoiding contact of the layers.

For the best protection of wooden products, they must be treated with stain (impregnation). The stain, penetrating deeply into the pores of the wood, enters into a chemical reaction with tannins in the growth rings and gives the tree a resistant water- and light-protective color. It also protects the tree from mold fungi, grinder beetles and other pests and infections. Modern liquid stain is divided into three groups: alcohol, oil and water.

Water stains are of two types: in the form of ready-to-use solutions and in the form of a powder, from which such a solution must be prepared. This is the only type of stain that does not need white alcohol, linseed oil and other solvents.The stains of this group have one major drawback: penetrating the tree, they raise its fibers, which makes the tree unprotected in front of an excess of moisture. Although, on the other hand, such wood processing allows you to emphasize and highlight its structure. Therefore, today it is the most common type of stain.

Alcohol stain is produced in the same two varieties: in finished form and in powder. This hand paint by hand with a brush can not be applied, but only from the spray gun, as it dries in almost seconds.

Oil stain is the most convenient to use. It is easy to apply it evenly, it does not lift wood fibers and dries quickly. In addition, mixing in oil dyes, with its help you can give the tree almost any shade. Oil stain is diluted with white alcohol or linseed oil.

For the treatment of wooden surfaces with wood stain, the following are used:

- paint brush;

- foam roller;

- manual or automatic sprayer .

All these tools for the staining of a tree are equivalent, and the choice should be guided solely by common sense. For example, a few dozen squares of wood flooring can be drowned with a paintbrush for a very long time, and you can’t handle bindings of window frames other than the brush.

The technique of processing the stain is no different from the usual painting. The only condition: since most of the stains dry quickly, you need to work quickly but carefully. It is important not to allow the layer of stain to dry until the work is completed, otherwise in this place there will be a significantly different seam from the rest of the surface. Therefore, you can not dial on the brush a lot of solution.

The stain is always applied parallel to the direction of the wood fibers. And you can not go to the processing of another shape or section without finishing the work with the first one. In places where the two sections are connected, it is necessary to carefully monitor that the applied layers of wood stain do not overlap each other.

Varnish for coating wooden surfaces

Depending on the method of production, varnishes are divided into several types: alkyd, nitro, polyurethane, oil, acrylic and alcohol.

Alkyd varnishes must be diluted with a solvent. The surface covered by them is protected from water and fire, does not fade in the sun. Acrylic lacquers create a film that is resistant to abrasion and slows the aging of wood. Nitrolacs have a common base with acrylic, but they dry much faster. However, they are not able to withstand the effects of moisture and ultraviolet radiation for a long time.

Polyurethane varnishes are characterized by increased wear resistance. They form a strong film on the surface of the tree, which dries quickly. It is enough to say that the wooden parts of the ships are treated with varnishes of this very group.

Oil varnishes used to be very popular, but today they are used mainly for treating the floor. Their main advantage is low, in comparison with other types of varnishes, price. They require mandatory dilution of linseed oil and dry for a long time.

Acrylic varnishes appeared relatively recently. Today it is the most versatile and convenient to use varnish for wood. They can perform both internal and external work. It is diluted with water and does not have a strong odor characteristic of other varnish groups. By its protective properties similar to alkyd varnishes, but much more economical to use.

Alcoholic paints are used exclusively for the restoration of antique furniture.

The technique of applying lacquer is similar to the technique of wood treatment with wood stain. For work you will need a roller or paint brush. Sometimes, if you need to handle hard-to-reach places, they use a foam sponge. Recently, the popularity of spray paint in cans, for the application of which does not need any tools. But the consumption of such varnish is much more against the traditional.

Usually varnish is applied in 2-3 layers. Regardless of the type of lacquer and its texture, the layers need to be made thin, otherwise smudges will be visible on the painted surface. The decision to work with a roller or brush depends solely on the amount of work and your preferences.

Work on the treatment of wooden surfaces with wood stain and varnish coating does not require any special qualification from the performer, therefore, it can be done by anyone who wants it. The main thing is to have enough patience and perseverance. And then the tree in your house will long please the eye with a noble shine and elegant appearance.

Good luck!