The wooden floor makes any room stylish and comfortable. This coating is convenient to use and allows you to create a unique design. Despite the motley variety of materials for finishing the floor, wood continues to be in the first place. It has a large list of advantages and only one drawback - the need for regular care. The correct processing of wooden floors will help to keep touching beauty.

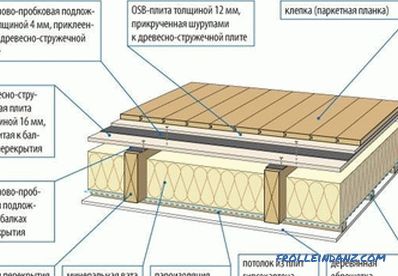

Floor layout.

Careful treatment of a wooden floor will help protect the array from the negative effects of external influences, as well as from pests. In order to choose a suitable type of coating, it is necessary to study all the offers of the building materials market, analyze the expediency of using each. It is advisable to listen to the advice of experts and make the right choice.

To protect a wooden floor from damage and destruction, you can use:

- oil paint;

- varnish;

- oil;

- wax.

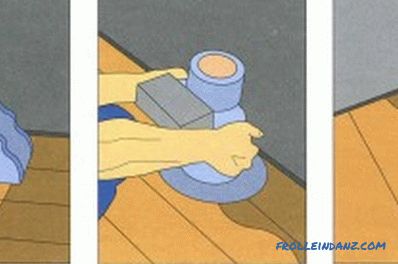

Floor sanding pattern.

Before covering a new or renovated floor with one of the means, it is possible to treat the surface with a stain, a liquid with wood protection properties. It is necessary to check that the nails and other fasteners are recessed into the array by a few millimeters. These depressions must be blocked with putty intended for woodworking. Only after these manipulations can you start to cover.

Oil paint - once the most common, but not the best material. It provides a fairly durable coating, successfully protects the array from destruction, but hides the magnificent natural texture of wood. To preserve the charm of the material, it is worth treating the wooden floor by another means.

Varnish varieties

Today varnish is the most popular tool for processing wooden surfaces. It effectively protects the array from destruction and preserves its structure, emphasizing the original appearance.

Base cleaning and dedusting scheme.

For interior work with wood, you can use one of the following types of varnish:

- Water soluble. This varnish favorably differs in the absence of caustic smell and environmental friendliness. It dries quickly and provides good adhesion. But when using it, it must be remembered that every 2-3 years it is necessary to update the coating, use only special rollers for application and be sure to maintain the humidity at the level of 50%.

- Alkyd. This type of lacquer has excellent durability and maintains the integrity of the coating even in places of active impact. But it dries long enough. In addition, it is important to ensure that the flow of funds does not exceed the standards specified by the manufacturer, otherwise the coating will peel off.

- Anhydrous polyurethane. The material has excellent wear resistance, it can be used in areas with high mechanical stress, for example, in the living room, hallway or even a cafe. But care must be taken during the work, if the moisture level of the wood mass exceeds 10%, unpresentable bubbles will appear on the surface of the varnish coating.

- Acid-curing varnish (formaldehyde). This tool will provide reliable coating resistant to mechanical and thermal effects. But when working with him it is necessary to observe precautions, work only in a respirator or entrust this stage of processing to professionals.

No matter what type of lacquer coating is chosen, it is necessary to study all the features of working with the material. This will avoid unpleasant surprises.

Impregnation with oil

Impregnation of wood with oil will retain the color and relief of the coating.

Oil floor protection is a very popular treatment method. Thanks to this coating, the wood mass will retain the maximum color and relief, which will emphasize the environmental friendliness of the material.

Floor treatment oil does not create a film on the surface of the board; it soaks it, providing additional protection. The floor will not be glossy, as is the case with varnish, but the durability and natural look are sure to please. It is possible to cover with oil a wooden floor even in places of high passability, for example, in a corridor.

It must be remembered that the oil coating emphasizes the relief and disadvantages of the board. If there are numerous flaws on the woody floor, it is better to pay attention to a different type of coating.

The coating of any surface with oil should fully comply with the recommendations of the manufacturer. Otherwise the color will be uneven. It is important to quickly remove excess funds, since the tree will darken in places where oily substance accumulates. Update this eco-friendly coating will have 2 times a year.

Difficulties with operating an oil-impregnated floor may arise in the first years. The surface will quickly become dirty. Later, after a few years, when the oil is completely absorbed, the problem will disappear.

The indisputable advantages of such a coating include a quick and easy update. To restore the site, it is enough to polish it and soak it again with oil. Once absorbed, it will be indistinguishable from the rest of the array.

Sanding with wax

Sanding the floor with wax will protect the array and give it the necessary gloss.

Waxing a wooden floor is ideal for lovers of glossy surfaces. This material will protect the array and give it the necessary gloss. Floor polishing wax is a natural material based on beeswax. It can be used as a stand alone coating or in tandem with oil.

You can apply the wax coating yourself. To do this, it is enough to distribute the product over the floor surface, let it dry and polish thoroughly. Repeat manipulations have 1-2 times a year.

Colored waxes are also presented on the market of building and finishing materials. With their help, you can slightly change the shade of the tree or give it a completely new color. The intensity of staining will depend on the number of layers of the product. This coating needs additional protection, it will provide an additional layer of colorless wax. When working with colored coatings should be careful, uneven application or insufficient careful polishing will lead to the formation of stains.

It is also possible to preserve the structure and color of the tree mass as much as possible, ensuring reliable protection. To do this, you should pay attention to the Scandinavian method of processing wooden floors. The prepared coating is regularly washed using a large amount of soap. The alkaline solution is gradually absorbed into the array and provides protection. The appearance of the floor does not change.

Whatever type of wood floor treatment is chosen, it is important to remember that this magnificent natural material is most afraid of moisture. Careful treatment and timely removal of spilled liquids will provide long service. And the warm - both visually and tactile - the floor will create comfort in the house for many years.

Didn't find the answer in the article? More information on the topic:

-

The process of painting a wooden floor

Recommendations for how to self-paint a wooden floor. Selection of necessary materials, tools. The process of painting and method of work.