There are many different pipelines in any home. This supply of hot and cold water, and heating system, and much more. To create them, you can use metal pipes. They have high strength and durability. This article will discuss how to connect metal-plastic pipes between themselves and with pipes made from other materials.

Why precisely metal-plastic

When making repairs to communications in the house, or making new ones, many people pay attention to metal-plastic pipes. And why exactly are they? The explanation for this lies in their advantages. Namely:

- They are resistant to corrosion. Due to the presence of polymers, such pipes do not rust or rot. So, they will serve for a very long time.

- Having an aluminum layer, they retain their shape well, while possessing elasticity. This property makes it possible to create systems of almost any configuration.

- Easy to install. Anyone can cope with the creation of communications, even without possessing special skills.

Layers of metal-plastic pipe

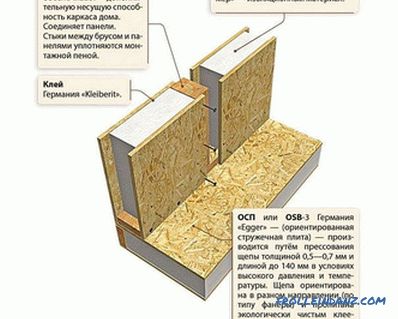

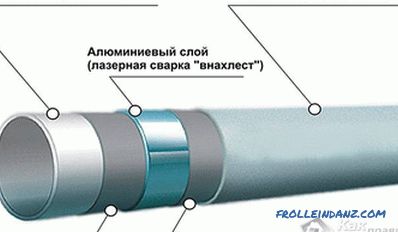

Layers of metal-plastic pipe

The structure gives all these advantages to metal-plastic pipes. It consists of several layers. The first (inner) layer consists of compacted or cross-linked polyethylene. Then there is a layer of glue on which a layer of aluminum is applied. Next in the "cake" is again glue, on which the last ingredient is applied - plastic.

But there are some drawbacks. For example, there are some limitations in the use of plastic pipes in hot water supply and heating systems. Also to the disadvantages can be attributed to the narrowed flow area of the joints (due to the use of special fittings). Such water supply should not be walled in the wall if it is assembled on threaded connections, because they need to be periodically compressed.

Connection by means of press-fittings

Press fittings angular in the pipeline

Press fittings angular in the pipeline

The joining of metal-plastic pipes with your own hands can be done in several ways, one of them is the use of press fittings. Such a docking is reliable, but not collapsible. This method is recommended by experts when laying hidden pipelines, since leakage at the junction is almost impossible.

For work, a special tool is needed - press tongs. It can be operated both manually and using electricity. You also need to stock up with special scissors for cutting pipes, a calibrator, a face picker, a straight fitting (if you need to connect pipes of different diameters or make a turn, then other varieties are used).

Connection of metal-plastic pipes using press-fittings

Connection of metal-plastic pipes using press-fittings

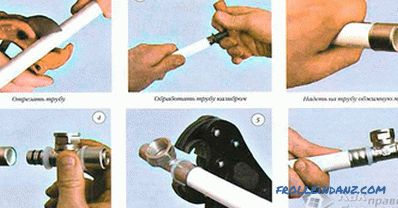

The sequence of operations is as follows:

- With the help of scissors we cut the pipe of the desired length.

- Then we process the end. First, align the edges with a calibrator and remove the chamfer from the inside. Then we process the outer side with a phascus pickup.

- Carefully inspect the fitting, especially the O-rings. If a defect is noticed, it is better to replace. If everything is normal, then we put on the pipe crimp coupling. The fitting fitting to the stop is inserted into the pipe.

- Then with the help of press tongs we crimp the clutch. If an electrical device is used, you cannot hold on to metal elements. In this case, it is best to carry out work in rubber gloves.

Connection leakage

Connection leakage

The correctness of the work performed can be checked by the shape of the coupling, it must have the appearance of regular rings. In this case, re-crimping is impossible. Such actions can lead to the formation of cracks and, therefore, to possible leaks.

Crimp fittings are non-separable

Crimp fittings are non-separable

Connections made with press fittings may last up to 50 years. At the same time, they easily withstand high pressure. But, as already mentioned, such connections are non-separable.

Use of compression fittings

Compression fittings

Compression fittings

There is another way to connect metal-plastic pipes - using compression fittings. This method is the most economical, since it does not require the use of additional tools and equipment. In addition, the connection itself is very simple to make, even without having any special skills.

The fittings themselves are a fitting that is equipped with a split ring and a cap nut. Each manufacturer can produce their own varieties. Therefore, experts recommend buying fittings from the same manufacturer as plastic pipes (sometimes the diameter may not fit). But whatever company the fitting, the principle of its installation is always the same. You will need:

- a pencil;

- a pipe cutter;

- a calibrator;

- a wrench.

Connection of metal-plastic pipes Use a pencil to measure the place of the future cut. Then cut with a pipe cutter the desired piece of pipe. Next (mandatory item), calibrate the hole. Then put a cap nut and o-rings on the end and insert the nozzle. To facilitate the work, you can moisten the rubber seals of the fitting with water. Then with a wrench, tighten the union nut. When working with a key, it is not necessary to apply excessive force, as it can damage the connection.

Connection of metal-plastic pipes Use a pencil to measure the place of the future cut. Then cut with a pipe cutter the desired piece of pipe. Next (mandatory item), calibrate the hole. Then put a cap nut and o-rings on the end and insert the nozzle. To facilitate the work, you can moisten the rubber seals of the fitting with water. Then with a wrench, tighten the union nut. When working with a key, it is not necessary to apply excessive force, as it can damage the connection.

As you can see, it is not difficult to connect two metal-plastic pipes in this way. In this joint is obtained collapsible. This can greatly simplify the repair and replacement of damaged areas. If there are any incomprehensible questions (for example, with the conduct of mandatory calibration), then you can watch videos from the Internet.

Connections of metal-plastic pipes with pipes from other materials

Fitting for connection of a metal-plastic pipe with pipes from other materials

Fitting for connection of a metal-plastic pipe with pipes from other materials

Very often, making the replacement of communications, it is necessary to connect metal-plastic pipes with pipes of other materials. In this case, you can also use several methods.

To connect the metal-plastic with metal pipes, use a compression fitting. It is important to do everything carefully and consistently. It is necessary to do the following:

- The first thing we do is metal pipe. If there is rust on it, then you should get rid of it (using a metal brush). Then we twist the fitting on the thread. It is better to use the old method of protection against leakage, winding tow on the thread. Then we twist the fitting on it.

- Now we take a metal-plastic pipe. We put a press washer with a nut on it and do the calibration.

- The next step is to put on the end of the metal-plastic pipe on the cone of the fitting, screwed to the metal one.

- Now with the spanner, tighten the nut. As a result, the washer must firmly compress the metal-plastic pipe.

Such a connection is quite strong and does not allow leakage. The main thing is to choose a fitting of the desired diameter.

Tee for connecting to a metal pipe If there is a need to connect metal-plastic with polypropylene pipe, then use special couplings. One end of such a product is soldered to a plastic pipe, and there is a thread at the second end. As a rule, a fitting with an external thread is soldered into the polypropylene pipe, into which a fitting for metal-plastic with an internal thread must be screwed. Then they just twist together.

Tee for connecting to a metal pipe If there is a need to connect metal-plastic with polypropylene pipe, then use special couplings. One end of such a product is soldered to a plastic pipe, and there is a thread at the second end. As a rule, a fitting with an external thread is soldered into the polypropylene pipe, into which a fitting for metal-plastic with an internal thread must be screwed. Then they just twist together.

Also on sale you can find fittings in the form of a tee, a corner and other structures. With their help, you can easily connect metal-plastic with polypropylene pipes. At the same time, experts recommend winding tow or fum tape on the thread to avoid leakage.

PVC pipes are combined with metal-plastic in the same ways as with polypropylene. At the same time, practically the same fittings and accessories intended for this type of pipes are used.

Video

Watch a video about metal pipes and find out the secret of connecting compression fittings:

This video shows the Rems Eco Press pliers designed for crimping press fittings: