Currently, in the private construction, purchased concrete slabs used as lintels are practically not used. Today, most suburban housing owners prefer to make door and window lintels with their own hands.

For self-construction of bulk concrete bridges, you do not need special skills at all. All that is required of you is to pay due attention to the materials of this article and follow all the instructions given in it.

Materials and tools

Boards for making formwork

Boards for making formwork

For the successful implementation of the delivered The tasks you will need are the following consumables:

- a set of cut boards of suitable thickness;

- a set of metal corners;

- thin reinforcing mesh;

- plastic film ;

- nails with a wide cap;

- self-tapping screws of the desired size;

- knitting wire.

Jigsaw for cutting wood

Jigsaw for cutting wood

As for the tool, you will need to work prepare:

- ordinary hammer;

- electric jigsaw (hacksaw);

- electric drill or screwdriver;

- mounting tool (pry bar);

- "trowel" (trowel);

- a bucket of small capacity.

Preparing the box

Manufacturing formwork

Manufacturing formwork

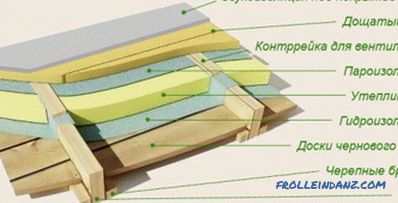

Arrangements for lintel begin with the manufacture of wooden frame (box), used for pouring concrete mix and obtaining a building element of a given shape. To install such a box, you will need one lower and two side wooden shields, from which you can later assemble the formwork.

The linear dimensions of the finished panels should correspond to the dimensions of the window opening, and the side panels should cover it both in height and in width. The lower shield is made exactly according to the size of the opening being closed. In the sides of the formwork, pre-prepared openings for the knitting wire, by means of which the shields will be held in a given position. The bottom and side surfaces of the boards are then laid with a plastic film, which is attached to the formwork with glass nails.

Fitting of fittings

Fitting of fittings

- The box assembly usually begins with the installation of the bottom shield, which the width and length are carefully adjusted to the dimensions of the window opening. The correctness of its installation is controlled horizontally with the help of a building level, after which several props are installed under this shield (taking into account the preservation of the level set at the level).

- The side shields are set in a certain sequence; at the same time one of them is first fixed on the wall (with the help of screws, for example) and only then it is fixed on the already mounted lower shield. Note that for walls lined with silicate or gas silicate blocks, this task is considerably simplified, since the shields can be fixed on their surface with the help of ordinary nails.

- The second side shield is also fixed first on the wall, and then mounted on the bottom of the box with self-tapping screws. When fixing the formwork, you should not save on self-tapping screws, because when you dismantle the structure you will be able to unscrew all the fasteners and use it for other purposes.

- In order to avoid the “collapse” of the shields under the pressure of the concrete mortar, the side walls of the structure are fastened together with a binding wire. Such wire (pre-cut into pieces) is pulled by a double ring into the previously prepared holes in the shields. After that, a reinforcing rod suitable for the size is inserted in the center of the twist, with which it is tightened.

- Then the finished reinforcing mesh is placed in the formwork. It is placed in such a way that the bars of the reinforcement do not touch the walls of the box; at the same time small stones are placed under its lower row.

It is best to use concrete mixed with fine gravel to fill improvised jumpers.

Filling jumpers and dismantling formwork

Filling window jumper

Filling window jumper

Concrete casting operations are recommended to be performed together; while the assistant will be able to serve you with a bucket of concrete, which is usually prepared at ground or floor level. Concrete should be poured very carefully, making sure that the composition is evenly distributed throughout the volume of the box and penetrated into all its cavities. In addition, when arranging the window jumpers with their own hands (in the process of leveling the concrete mix), it is necessary to ensure that the fill level coincides with the upper cut of the brickwork.

The dismantling of the formwork usually begins with the cutting of the knitting wire, after which it will be possible to proceed to the unscrewing of the self-tapping screws fastening the shields together.Then by mounting the side shields are separated from the finished lintel, after which the support is removed and the lower shield is removed.

Manufactured jumper

Manufactured jumper

The surface of the resulting jumper often looks not quite perfect and, of course, needs in additional processing. To do this, first remove the remnants of the wire, and then in order to remove all irregularities, plaster its surface.

Video

About the pouring of reinforced concrete jumpers in practice, see the following video:

Photo

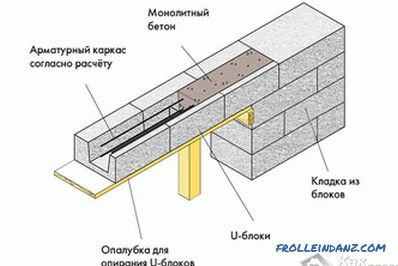

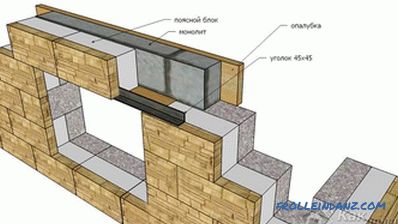

Setting the jumper using U-blocks

Setting the jumper using U-blocks

Production scheme of a monolithic jumper

Production scheme of a monolithic jumper

Reinforcement framework for the window lintel

Reinforcement framework for the window lintel

Prepared formwork

Prepared formwork

Jumper after pouring concrete

Jumper after pouring concrete

Removing formwork

Removing formwork