For storing things most often used cabinets that are made with your own hands. Many people think that it is very difficult to make a closet with your own hands and this is only possible for people who have special skills. In fact, we must follow the advice of specialists, then everything will definitely work out. And there is nothing difficult to make furniture with their own hands from the wall paneling without much difficulty.

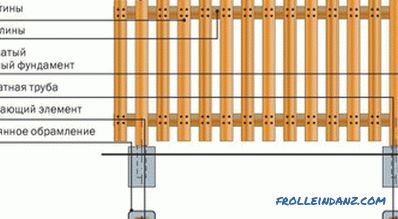

Framed wardrobe frame frame.

For the manufacture of a wardrobe from the wall panel you need to purchase the following materials:

- For the framework, you will need bars made of wood 40 x 40 mm in size. For the sake of economy, it is recommended to buy pine bars, but you need to ensure that they are perfectly dry, clean, no signs of rotting are allowed.

- To connect, you must use metal corners.

- To make the door frame, you will need boards or bars (thin).

- For cladding work, you need lining, which is also necessary for doors.

- As a material for the manufacture of shelves, you can use boards or thick chipboard sheets.

- Handles, hinges, locks should be used for the wardrobe accessories.

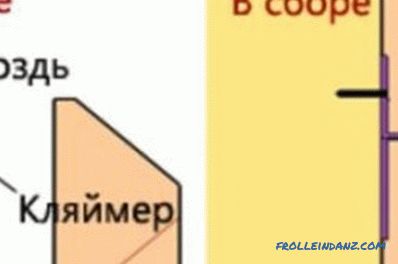

- For fasteners, you need to stock up with screws on wood, nails and clamps for lining.

As for the list of tools, it looks like this:

- The screwdriver, which must be equipped with a magnetic head.

- Saber saw, you can use a circular saw.

- Construction level, roulette.

- The hammer.

Before you make a cabinet from the wall panel, you must carefully consider the choice of material.

Lining fastening scheme.

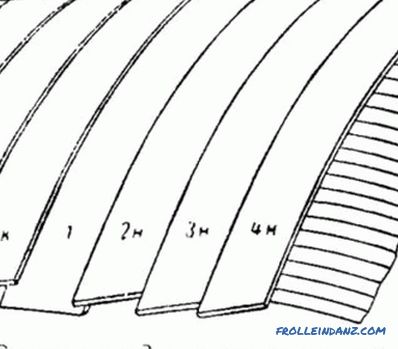

Lining from wood from those wood species that contain a small amount of resin is perfect; in this respect, oak, linden and ash should be noted. If we talk about the class of lining, then the higher it is, the more attractive will be the appearance. It all depends on financial opportunities. No need to buy a wall panel class, which is technical and for the manufacture of furniture is not suitable.

As for the amount of material required, it all depends on what kind of construction is planned. If it is planned to use the walls of the room as a wall, then lining will be needed only to sheathe the doors. For the back of the cabinet it is recommended to use laminated fiberboard, which is durable and durable.

How is the installation of the frame?

Types of wall paneling.

The cabinet from the wall panel should be mounted on the basis of a wooden frame. The frame is performed in the following sequence:

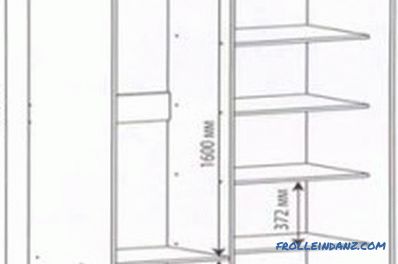

- First you need to assemble the front and rear frame, which means connecting the bars with a length of 1.5 and 1.8 m, for this purpose metal frames are used.

- Plywood can be laid on the floor, it acts as the role of the bottom of the cabinet. The parallel bars can be joined without the use of corners, for this you need to use self-tapping screws, the length of which is 60-75 mm.

- The rear wall of the cabinet, which is made of laminated chipboard, should be attached to the back frame with self-tapping screws or a construction stapler.

- The back frame with the wall is attached to the back wall, then fixed with anchors, they must be level.

- Inside the cabinet it is necessary to make mounting of the rails, on which then the shelves should be laid.

At this, the manufacture of the frame can be considered complete.

Cabinet lining with lining do-it-yourself

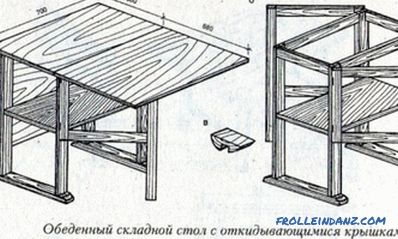

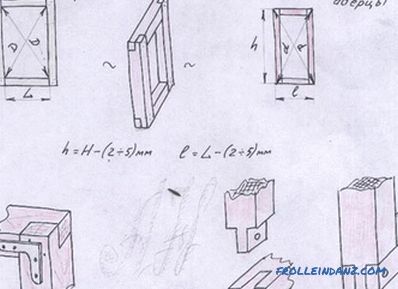

Dimensions of the cabinet.

A clapboard cabinet cladding is most often the manufacture of attractive exterior doors. This is done as follows:

- It is necessary to take a board (it is strongly recommended to use the thinnest board possible), to assemble from it a frame of appropriate dimensions.

- In order to achieve the required rigidity, you need to add a jumper to the frame (it has the shape of a rectangle) (it is transverse, but you can also make a diagonal one).

- The frame is laid on the floor, lining is attached to it, cut to the appropriate dimensions, and all this is fastened with nails. It is recommended to use the wall panel, which has the maximum subtlety, then you can not be afraid that the door will be very heavy. After the cladding work has come to an end, decorative trim plates should be attached to its door, and a handle is mounted on the back side.

The final touch in the manufacture of furniture is its varnishing. The cabinet must be coated with a protective varnish, thus, not only improves the appearance, but also greatly prolongs its life.

Thus, it turns out high-quality furniture made from the lining itself. And despite the fact that the manufacture of such furniture is no different complexity, it is not only able to accommodate a large number of different things, but will also serve as an excellent interior decoration.And there is no doubt that all friends, relatives and acquaintances will admire such a work of art!

Didn't find the answer in the article? More information on the topic:

-

How to make wood veneer?

Information on how veneers are made. Three ways of industrial manufacture of veneer. Making veneer your own hands. Finishing veneer of various surfaces.