You can try to identify some traits of the host’s character by the type of the enclosure of the infield. Stone or metal fences, deaf and high, leaving only the upper part of the house visible, suggest that people place safety above aesthetic preferences, and openness and hospitality are not the main qualities of his nature. The installation of wooden fences is more typical of sociable people, whose life is held in front of their neighbors and a fence made of natural material for which is not a way to hide or avoid communication, but a symbolic definition of the perimeter of the site, which serves mostly as decoration.

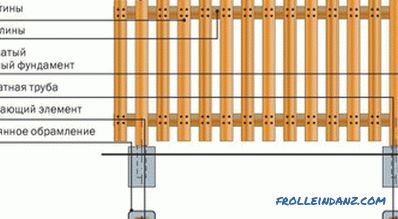

The scheme of the wooden fence.

Wood processing before installing a wooden fence

One of the biggest advantages of wooden fences is the reasonable price of the material of manufacture and the simplicity of its processing and installation. The wood is perfectly cut and polished, fired and painted. The only thing that needs to be done in order for the fence to last for a long time and not to require permanent restoration, to take into account all the rules for processing wood during its construction, and you can count on durability and a beautiful appearance.

Whatever the species of wood from which the lumber is made, the raw material will be hygroscopic, that is, the property of absorbing moisture. The close proximity of the fence to the ground and operation

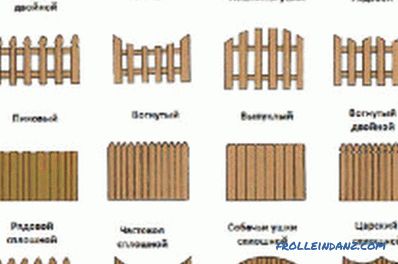

Scheme of varieties of wooden fences.

in the open air will contribute to the swelling of the material and its subsequent drying under the sunlight. The wood will be deformed and warped, may form cracks. Therefore, before manufacturing, all wooden parts should be treated with a water-repellent compound, paying particular attention to the stands that will be in direct contact with the soil.

Another precaution that will ensure the durability of wooden fences, the impregnation of wood with antiseptic composition.

Microorganisms that lead to the appearance of mold and fungus readily multiply in the natural material, and insects feeding on the tree settle: tree borers and bark beetles. The measures taken will prevent damage and rotting boards, will not long to think about repairing, painting or installing a new fence.

Choosing lumber for a wooden fence

It does not make sense to buy expensive wood for the fence to be installed, coniferous woods are perfect for this purpose.

The main thing is that the selected forest is smooth, has no significant damage and knots on the surface and the wood is well dried. As for the type of material, it depends on what kind of fence is planned for production. For a plank variant, a board is usually purchased with a thickness of 10-20 mm, and its width can vary within 10-15 cm. For a complete fence, lining is better, which has projections and grooves on the sides for reliable connection of parts. One of the budget options for wooden fences - a picket fence, is made of slats, usually having dimensions of 25x50x1000 mm, or can be purchased in the form of ready-made modules, which can only be mounted on the supporting posts. As transverse mounts for different types of fencing, it is customary to use a wooden beam, the cross section of which is 50x50 - this size is the most convenient during installation.

Installation of the fence

For work on the manufacture of any type of wooden fence you will need:

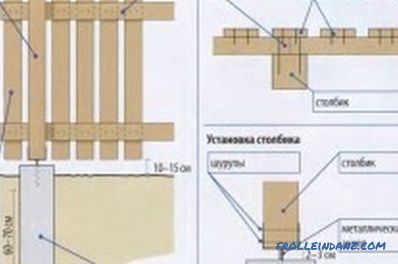

Installation scheme of a wooden fence.

- bayonet shovel;

- hacksaw;

- ax;

- screwdriver or drill with nozzles;

- self-tapping screws ;

- putty on wood;

- sandpaper;

- primer;

- paint and brush.

Construction should be carried out in the summer, in dry weather. Installation begins with determining the exact location of the support pillars and digging holes for them. The supports may be of various materials - brick posts, metal pipes or concrete structures installed on the foundation, but for the budget option the installation of wooden posts will be the most acceptable. If short scraps of a metal pipe of a suitable diameter are installed in the prepared pits or simply to fill the base of the supports with concrete, the fence will receive additional stability and protection of the lower end of the pillars from soil moisture. With the same purpose, the lower parts can be treated with resin or wrapped in a layer of roofing material.

The installation of the cross beams, which will serve as the basis for the selected lumber, is carried out when installed at a distance of 25-30 cm from the ground. In order to secure metal fasteners from rust, self-tapping screws or nails can be dipped in drying oil before twisting.

A fence, the boards of which, before starting work, were cut at an angle on the upper part, will not allow rain and snow to linger on their ends and provoke wood rotting. If you do not do this and leave the end cuts straight, then during installation it is advisable to build a visor in the form of a longitudinal facing plate to protect it from precipitation. At the last stage, the structure is painted or varnished, which will favorably emphasize the natural texture of natural wood.

Didn't find the answer in the article? More information on the topic:

-

How to make furniture yourself

How to make furniture yourself. What are the materials, and what is their difference? Variants of the drawings, as well as a description of the manufacture of an example. What else you need to know when deciding to do this kind of work?