After reading this article, you can learn how to easily and quickly warm your house outside. It discusses in detail all the stages of the insulation work, and also gives tips on choosing the right material. In particular, we consider how to make wall insulation foam plastic with their own hands. It will be inexpensive, and the effect will give a very tangible. We will tell in detail about this method.

Preparing the surface of the walls

In order for the thermal insulation to be of high-quality and last for a long time, it is necessary to prepare the insulated surface well. This process is quite long, and it will take a lot of effort. But the result is worth the time and effort spent.

If you are doing a new home weatherization, then you do not need to do some things.

# 1. First of all, you will have to remove everything that may interfere with the work from external walls. These are drainpipes, ventilation grilles, air conditioners, lamps with spotlights and wires. If the brick house is old enough, then on its facade there may be decorations framing the cornices and windows. They will have to sacrifice, gently knocking.

# 2. In the event that there is plaster on the walls, we will test it for strength - tap the surface. All irregularities and slopes are checked with a plumb line, rule or cord of sufficient length. All errors should be noted as small, so as not to miss a single flaw. As a rule, when checking, it turns out that the walls are far from ideal. They are not only not very even, but the plaster in some places rests on the "honest word". Do not take up the insulation, discovering these shortcomings. First, remove these pieces of plaster, and then work with a chisel, knocking down concrete surges and excess mortar between bricks.

# 3. If the facade was painted with oil paint, then it cannot remain on it. In this case, the paint will have to tear. Because of its reduced adhesive properties of the surface. Well, about the fact that it is necessary to remove the mold fungus, fat and rust, as well as the salt deposit, perhaps, everyone knows.

# 4. If there are sufficiently large irregularities and cracks on the walls (more than 2 millimeters), then they should be primed. To do this, use a deep penetration primer, wielding a special brush called paint. It will make this work faster and more accurate. When the primer dries well, you can apply cement putty for exterior work and putty cracks.

# 5. In the case when the irregularities are very large — more than 1.5 centimeters — we also ground them first. And then we put lighthouses on which we put plaster composition.

# 6. The walls are primed with brick once, from cellular concrete 2 times. You can cover a large brush or roller.

Sometimes, part of the communications is left on the wall surface, covering them with insulation. In order not to damage them, hammering dowels for fixing polystyrene foam, it is necessary to make a detailed plan of their location.

Fasten the starting profile

Having studied the project, we calculate the location of the lower boundary of the walls, which must be insulated with foam plastic. Now we take the hydraulic level, measuring this boundary at all external and internal corners of the house. We stretch the cord along these points. It is along this line that we will have to establish a starting profile on which the lower row of plates of thermal insulation material will hold. Otherwise, until the glue dries, the plates can move.

The size of the starting plate is selected according to the width of our heat insulator. Fasten it with a six-millimeter dowel-nails, placing them every 30 or 35 centimeters. An arching element for dowels are driven nails, which should be put on washers. The joints of the starting strips in the corners of the house do or oblique cut, or using a corner connector. To prevent temperature fluctuations from deforming the structure, we place plastic connecting elements on the ends between the profiles of the base. With overlapping of profiles is not allowed.

For safety, check the level of attachment of the starting profile.

Glue the insulation

Knead the glue

In order for the glue to not thicken too much or dry, it must all be used in an hour and a half to two. So we make the right amount of adhesive mixture on the spot. To do this, we take a large plastic bucket and pour water into it. Then slowly pour the adhesive into it. In order not to get lumps, put the mixer on the drill attachment, turn it on at low speed and stir the mixture until no lump remains. We are waiting for 5 minutes for the glue to swell, then for 2 minutes we turn on the drill again and mix. If after a while the glue has thickened slightly, you just need to mix it again, without adding water to it.

Apply adhesive to the foam plates

According to the outside wall insulation technology using foam, the adhesive can be applied to the insulation in different ways. It all depends on how smooth the walls are at our house.

Method 1 - used when surface drops reach 1.5 centimeters. In this case, apply the adhesive mixture on all sides of the foam plate, retreating from the edge by 2 centimeters. The same thickness (2 centimeters) should be a layer of glue. In order for the plates to keep pace with the central part of the plate, glue beacons with a diameter of about 10 centimeters are evenly placed 5-7 times in this place (0.5 square meters).

Example of applying adhesive.

Method 2 - used when wall irregularities are less than 1 centimeter. Along the perimeter of the plates, as well as in their central part we apply glue strips ranging in width from 3 to 4 centimeters. As a result, from half to 60% of the surface should be covered with adhesive. When the insulation is pressed against the wall, the glue will be distributed and will take up all the space.

Important: in order to avoid air traffic jams, never make adhesive strips solid. They should have a dotted look.

Method 3 - used when the walls are almost flat, and the errors are no more than 5 millimeters. In this case, we arm ourselves with a special notched trowel, applying glue to the entire base of the plates. Comb tooth size - centimeter per centimeter.

Rules for installing insulation on walls

Once the glue has been applied, you cannot delay it. Within 20 minutes you have to glue all the plates into place. At first we apply sheets of expanded polystyrene, slightly shifting them away from the place where they need to be glued. This distance should be 2 - 3 centimeters. Then with the help of the building rule or the trowel we press the heater to the adjacent plates. The adhesive that will come out from the inside of the foam and in the corners must be removed immediately.

Put the sheet with the offset and press it to the next.

The correct installation of each foam plate is checked using a level. We also use control cords and the rule, determining all deviations from the plane.

Each sheet is checked by level.

The plates must be laid tightly, at a distance of no more than 2 millimeters from each other. In case of gaps of greater width, they must be sealed. To do this, take either construction foam or long and narrow pieces of foam. Glue in the seams should not be, and the difference in thickness at the joints is allowed no more than 3 millimeters.

Important: if you move the plates until the glue hardens, they can stick badly. Therefore, when there is a need to correct some shortcomings, it is better to remove the plate. Removing a layer of adhesive mixture from it, we smear fresh glue and put the sheet in place again.

When installing insulation, we work from the bottom up, starting from the basement profile. We pay special attention to the lowest row of plates, which will be decisive. The easiest way to do this is to put the first and last plates, and between them pull the cord, attaching it to the top of the sheets. On this cord and expose the remaining foam plates. The next row is laid out with offset joints. It must be at least 20 centimeters. However, it is even better to lay the rows of insulation in a staggered manner, making the offset to half the slab.

The joints of the foam should be closed, for this we glue them with offset.

When laying the plates, we carefully look at how their joints relate to openings for windows and doors. It is impossible that they pass along the same vertical line with the slopes. Optimally, if the joint passes or under the opening, or above it. At the same time, the technology of thermal insulation of facades with polyfoam provides that the amount of displacement should be at least 20 centimeters.

There is also such an option: the wall is made of one material, and then a part of another material is attached. For example, a brick, OSB or foam concrete are connected. The junction of two adjacent plates of insulation should be located not less than 10 centimeters from the border of these materials. And if the walls have protrusions or depressions that need to be insulated, then these places are also covered with a heat insulator not less than 10 centimeters.

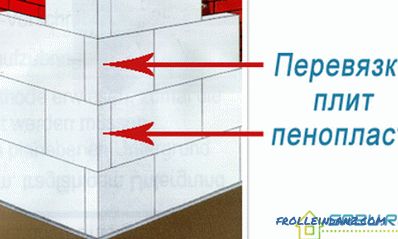

In the corners of the house, both inside and outside, the plates are joined by teeth, i.e., with dressing. To vertically not formed a long seam, causing cracks, from the insulation required entry on the adjacent wall. In the corners and on the slopes of the foam plate plates are placed with a margin, which should allow to do the dressing. As soon as the glue on the corner grabs, the protruding surplus plates must be cut off. To cut the foam gently, take a thin file with frequent teeth or a wide knife. It is necessary to cut under the ruler or square from the metal.

In the corners of the plate must be tied together.

When weathe the slopes, we install sheets of insulation right next to the window and door openings. To do this, you need a polyurethane foam sealing tape or an adjacent profile. If tape is used, it is glued directly onto the door frame. When a heater is attached to it, it is compressed, becoming thinner by about a third. Warming window located on the facade, lead insulation to its frame by 2 centimeters, no less. Pregluing the entire window opening with polyurethane tape.

In the case of a deformation seam on the wall at the location of the insulation, a slit is made from 1 to 1.2 centimeters in size. With this effort, we insert a polyethylene foam cord into the gap, squeezing it by a third.

Dowels fix the insulation

When the glue dries (usually it happens in 3 days), you can start the final fixing of the insulation. For this purpose, elastic plastic dowels are used with a wide perforated hat in the form of an umbrella. They are fixed by a driven nail or a screwed-in pin. Nails can be metal or plastic. To prevent cold bridges, it is better to choose the option with plastic nails. The length of the dowel determines the thickness of the heat insulator and the material from which the walls are made. The dowel should go into concrete by 5 centimeters, into brick - 9 centimeters, and for cellular blocks - 12 centimeters.

Important: dowels that have a metal rod inside should not be used. This is fraught with the appearance of cold bridges.

The dowel is fixed in all corners of the plate, as well as in the center. Per 1 square meter is from 6 to 8 dowels. Next to the slopes of doors and windows, at the corners and near the base of fasteners will need more. From the edges of the plates, they must recede by 20 centimeters. How many additional dowels to take, and at what distance from each other to attach them, depends on several factors. This, in particular, the size of sheets of heat insulator, the size of the house, wind strength and quality of dowels.

Before using fasteners, we make holes for it using a perforator.

The drilling depth must be 1 or 1.5 centimeters more than the length of the dowel.

After cleaning the holes from dust, we hammer in the expansion nails with a rubber hammer. If not nails are used, but pins, then they are screwed in with a screwdriver. Dowel caps should not stick out strongly above the insulation plane. This distance can be no more than a millimeter.

You may find the following materials useful:

- How to choose a punch - the criteria for choosing a punch for home or permanent job.

- How to drill concrete, metal, tile and wood.

Do not forget that it is necessary to observe the perpendicularity of fasteners relative to the surface of the walls. From time to time we check how firmly the dowels are held, carefully trying to tear them off.

We lay the reinforcing layer

Installation of the auxiliary reinforcing mesh

In order to avoid cracks in the corners of the openings of windows and doors, these places should be glued with pieces of reinforcing mesh 20 by 30 centimeters . This reinforcing mesh is mounted in the same way as the base layer for reinforcement.

When insulating facades with foam plastic in the lower part, up to two meters in height, an additional layer of reinforcing mesh should be laid. He will protect the wall from destruction.

Installation of perforated corners

Perforated corners are used to strengthen the corners of the house, as well as the slopes and decorative elements. They are made of plastic or aluminum, and along the edges of them are attached pieces of reinforcing mesh. To fix the corners, they are smeared with glue (including the net), and then pressed down with a spatula to the insulation. Pre-cut corners. The glue that will protrude through the mesh and perforations must be smoothed. In the corners, we connect profiles closely together, cutting off the grid and shelves at an angle of 45 degrees.

The glued corner.

Installation of the main reinforcing layer

When the additional layer dries and all corners are securely fastened, you can fix the main reinforcement layer. For this purpose, a special facade mesh made of fiberglass is used. It is alkaline resistant and does not stretch. A strip of such a grid with a width of 5 centimeters can withstand a load of up to 1.25 kilonewtons.

To glue this mesh and protect the insulation, use a special solution. It has not such a composition as the adhesive mixture, but it is prepared in approximately the same way.

Before reinforcing, foam plates must be sanded. This will allow smoothing the irregularities in the joints of insulation plates. We grind polystyrene by a grater and a large emery paper. After that, well clean the surface of the insulation and apply the solution with a layer of 2 millimeters.

The reinforcing mesh is cut into pieces, the size of which corresponds to the height of the wall.The solution is applied to the surface of the walls vertically with a layer equal to the width of the grid. For this we use a scraper or metal grater. It is convenient to remove excess glue with a notched trowel in order to form grooves. Then apply the net to the wall, embedding it in the solution and pressing it with a float or a smooth spatula.

After leveling, the grid should not be visible on the surface.

Smooth the grid gently, from the middle to the edges. Excess glue is distributed on the wall plane.

Important: we do not stretch the grid strongly, and do not press it against the thermal insulation. Her place - in the middle between the wall and insulation.

As soon as the mesh is glued, we do not wait for the mortar to dry and apply another layer of it, but leave a free edge of 10 cm. Its thickness is the same as the previous one - 2 millimeters . On the free edge of a width of 10 centimeters impose a second strip of the grid. The top layer of the solution should completely cover the grid, it should not look out from under it. After that, all of the above steps are repeated with the second grid line. The bands should overlap each other by 10 centimeters.

We are waiting for tomorrow, and in the morning it is already possible to seal the irregularities with a putty. It's okay that it has not dried completely. But if the irregularities are large enough, you will have to wait for drying, and then apply an additional layer of glue.

Useful tips on thermal insulation of exterior walls with foam

# 1. Remember that wall insulation outside of the foam should be done at a positive temperature, not lower than 5 degrees and not higher than 25 degrees. Air humidity can be up to 80 percent. It is not allowed to expose insulation to solar radiation, as well as leave it in the rain and wind. This applies to all phases of work.

# 2. With the help of sturdy scaffolding or scaffolding, it must be possible to reach any part of the wall, as well as to the side surfaces. To make it convenient to work, scaffoldings are mounted 20 or 30 centimeters from the walls.

# 3. With plastic wrap, we close the doors and windows, securing it with masking tape. You should also close the brackets, communications, passing outside the building. We will protect the blind area and the porch with cardboard or the same film. After painting works are completed, we remove the adhesive tape.

# 4. If the foam insulation on the wall was for a long time without reinforcement, it will turn yellow and start “dusting”. This yellowness must be cleaned with emery cloth.

# 5. If experience is not enough, start working from the wall that is least noticeable. Or you can start to insulate the most simple surface. Gradually, the technology will be developed.

# 6. In the event that warming should be suspended for the winter time, provide for the installation of reinforcing layers. Parapets and bevels will be securely closed if special protective metal elements are installed. Do not forget about the window ebb.

# 7. When planning work try to make continuous all the "wet" stages of work on the same wall. This is especially true of reinforcement and decoration.

Only suitable materials should be used for this method of insulation. It is necessary to take polystyrene foam, which has a density of at least 25 kilograms per cubic meter. Never glue it or the mesh with tile glue. Use only special solutions, and then insulation of the outer walls with foam plastic will last for a long time with the desired result.

Video: Wall insulation with foam