Composite metal tile is a type of profiled roofing materials manufactured on the basis of steel sheet with a thickness of about 0.45-0.55 mm. During its production, a special passivating layer of aluminum is applied on the sheet base, which is covered with a crumb of natural stone (most often - basalt) on top.

The use of a combined protective and decorative coating allows you to protect the metal base from corrosion, and also gives the roof covering a fairly attractive appearance.

Decorative coating of composite metal tile

Decorative coating of composite metal tile

In contrast to classical materials with a polymeric protective layer, this the variety is produced in the form of sheets of smaller dimensions, in the form of its copying the traditional tiles of ceramics. That is why the installation of composite metal tile has certain features that will be considered by us later.

Features of forming sheet blanks

Sheet blanks

Sheet blanks

The main difference between the installation technique of metal tile from other roofing (slate, corrugated, ondulin, etc.) consists in a clear distinction between the upper and lower rows of the stingray, located on the edges of the mounted coating. This circumstance will require special care from the contractor when calculating the required amount of starting material, since the interchangeability of sheet blanks in this case is extremely limited (as is the possibility of fitting the sheets in size).

The undesirability of cutting sheet material is due to the fact that this reduces the strength of the polymer and passivating coatings, which makes the metal sheet vulnerable to moisture. That is why when laying this covering it is recommended to use combinations of sheets with different numbers of waves (the most popular sizes include three, six and twelve waves in the sheet).

In such places, the tile has to be cut

In such places, the tile has to be cut

However, in certain situations (when arranging a hip or tent roof , for example) you still have to cut the metal tile, and any of the following tools can be used to cut it:

- metal shears (manual);

- so-called punch shears (electric) ;

- hacksaw;

- electric jigsaw with matching blade;

- circular saw.

Laying order

Laying order of composite tile

Laying order of composite tile

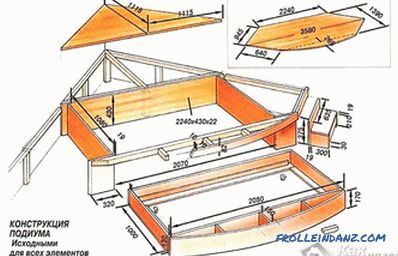

Installation of metal tile involves the use of special crates, arranged in accordance with the size of sheet blanks.

Composite tiles can be laid both from the bottom up, and starting from the ridge (that is, from top to bottom). In the second case, already laid blanks are slightly raised, after which another sheet of the next row is fed under them. After that, in the area of overlapping of two sheets, a common fastening element is nailed to the crate.

In the process of laying the following requirements must be met:

- Sheets must be laid in a staggered manner, which is ensured by a slight lateral displacement between adjacent rows. Moreover, when forming overlaps in one place should not be collected more than three sheets.

- The values of lateral displacement and overlap in the overlap zones are usually selected on the basis of the technical characteristics of the collection of roofing material you use (these parameters are usually indicated in the instructions for its use).

- A typical offset between the rows is chosen to be approximately one third of the width of the roofing sheet (without disturbing the given roof pattern). As for the side overlap of one sheet to another - it should be placed on at least one wave crest.

- To fix the tile to the crate, special nails are used, driven into it at an angle of 45º and supplied with roofing material.

Nailing nails into metal

Nailing nails into metal

Video

This video is assembly instructions for Metrotile composite tile: