One of the cheapest types of sawn timber is unedged board. It is characterized by high decorative properties, but in construction work, design often does not play a special role.

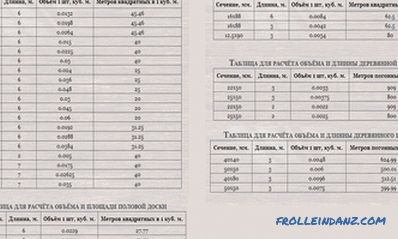

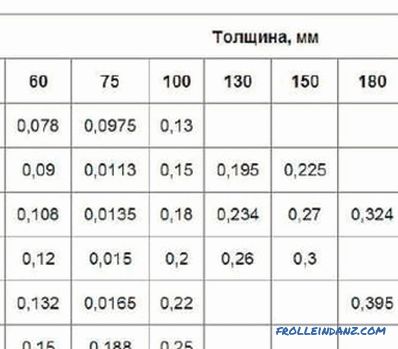

Tables for calculating the volumes and areas of various types of boards.

Cladding, scaffolding, decking, roof sheathing are often made of this material. It is widely used in the construction of utility rooms, the construction of formwork, temporary shelters, storage facilities, all sorts of rough work. But sometimes - and for design purposes: to create a specific finish for untreated wood in the interiors of pubs, bars, restaurants, cafes, etc.

Method of calculating the cubature

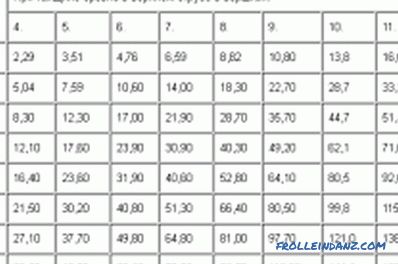

Calculate the weight of a cubic meter of wood.

A unedged board is just a lengthwise sawn log with wands on either side. It is due to the blisters, on which the bark is often left, a specific design effect is achieved. In this regard, the shape of 1 piece of this lumber may vary depending on which part of the log she sawed.

That is, it is impossible, as in the case of a cut board, to calculate the volume of 1 piece using the rectangular parallelepiped formula, and then calculate their number in cubic meters, for this timber only length and thickness are fixed, but not width.

The width varies within rather wide limits and depends both on the parameters of the logs themselves and on whether this particular specimen or the side (the one closer to the crook) was cut from the middle part of the former trunk.

Of course, it is possible to calculate the approximate average parameters of one unedged board in each specific case, but this makes little sense. Usually the calculation is made differently - in accordance with the area of the walls.

That is, first the total area is calculated, and then the thickness of the unedged board is taken into account (based on the needs). For example, if you need to sheathe a structure, then consider the area of its walls and multiply by the thickness of the boards used. Suppose you need to sheathe a back room of 4x6 m and a height of 3 m with boards 25 mm thick. Then there are 2 smaller walls of 4x3 m and 2 large 6x3 m. Their total area is thus 4x3 + 4x3 + 6x3 + 6x3 = 60 m². Multiply by thickness (millimeters for this translate into meters): 60x0.025 = 1.5 m³. There is no need to take into account the width of individual boards: the total cubic capacity will not change, and lumber is sold in cubes, not pieces.

Cubic table

Nevertheless, the average parameters of the conditional 1 piece should also be remembered. For an approximate preliminary calculation, this knowledge may be useful. Moreover, the table of cubature of the unedged board itself is simple and consists of only 3 lines. This timber is produced in three thickness standards: 25, 40 and 50 mm. The standard length is 6 m. Average volumes are as follows:

- if the thickness is 25 mm - the volume is 0.0294 m³;

- 40 mm - 0.05 m³;

- 50 mm - 0.071 m³.

The cubature of boards of non-standard length (3 or 4 m, these are also sometimes found on sale) can be calculated from the table indicated by multiplying the corresponding value by 0.5 or 2 / 3

Didn't find the answer in the article? More information on the topic:

-

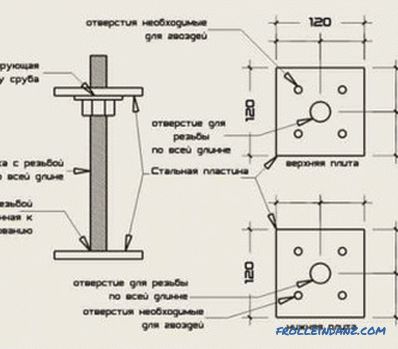

How to calculate the cost of timber per house?

Information that gives an idea of how to calculate the beam for the construction of a log house. The parameters of the lumber and log walls, which are required when calculating the flow.

-

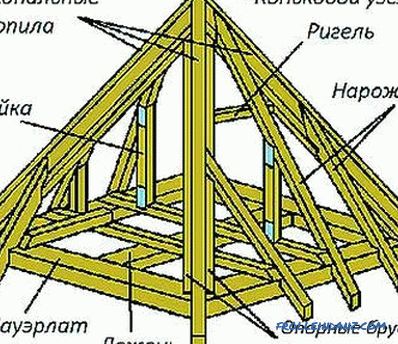

Perform the calculation of roof rafters

The calculation of the rafters includes the determination of the pitch of the racks, the section of the timber. The configuration of the roof, the scheme of supporting the legs on the mauerlat, the joints in the ridge, the use of crossbars, racks are taken into account.

-

What influences the shrinkage of the log house?

Shrinkage of the log: factors that affect it. Preventive measures and work during the shrinkage process. Tools and materials needed for work.