When working with a hand saw, it is always necessary to have a support. This is not a process with chainsaws where everything is easier. Safety of the operator directly depends on this. Such a table will be convenient for work not only for a professional, but even more so for an amateur, not to mention novices. Therefore, to equip his workshop with everything necessary is required by each master.

Combining high maneuverability and high productivity, the hand-held circular saw is an indispensable tool for smooth cutting of various materials.

In order not to waste money, you should think about how to assemble a table for a manual circular saw with your own hands. He will be able to help out when he has to deal with large wood-based panels.

Some features and characteristics of the tool itself

In order to have an idea of the importance of an additional device (the table itself), it is necessary to present the characteristics of the tool itself so that the table is made not as anything, but reliably. On this depends not only the quality of work, but also the safety of the person himself.

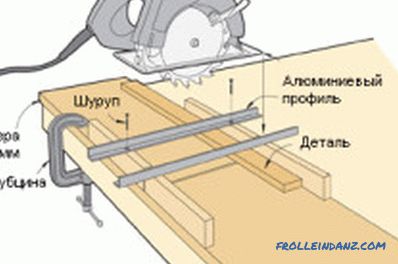

The circuit diagram of the manual circular saw.

The circular saw is such a device designed for cutting natural wood and its artificial counterparts. Such a tool is convenient to work absolutely in any direction. In many ways, the safety of working with a saw depends on the accuracy of the guides and on how reliably the cutting body is limited.

In order for the cutting process to be comfortable and not physically overloaded, it is very important that the tool is properly balanced. This point can be checked even when the device is turned off. Modern technology has provided circular saws "brains", that is, electronics. Such control allows you to choose the speed of work, and at the start to give a smoother course. And in the case when the saw begins to experience a load, the system automatically adds power.

It should be noted that the power of the saw motor is directly proportional to the diameter of the disc, since the torque parameter depends on it. Thus, it is possible to overcome the resistance of sawing, which arises from the fact that the lever of force of resistance of the material is extended. Therefore, in order for the saw to work better, it is necessary with a relatively small disc diameter to take a device with good power.

Types of discs for a manual circular saw.

The operation of such equipment involves the production of a large number of sawdust. As a result, the floor acquires a sliding surface, and the air is saturated with dust, which makes it difficult to breathe. Also soiled clothes. To avoid these troubles, it is necessary that the saw had a pipe for dust removal. Usually it is located on the top rail and acts in such a way that all shavings and sawdust fly away to the side. Alternatively, you can also use a vacuum cleaner, the hose of which is connected to the nozzle.

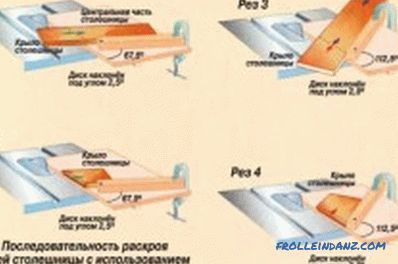

In order to be able to move the canvas under the slope (up to 45 °), it is necessary to loosen the clamps on the body. For the variation of the angle, the orientation is taken on a special scale. In order to see this figure accurately, you need to make a trial cut. The slope will affect the depth of cut.

How to work with a saw at an angle

Circular saw operation check circuit.

Circular saw is a very dangerous tool. Therefore, each manufacturer equips its products with a fuse button, which is most often located on the side of the handle. Without pressing it, the saw will not work.

Since the cut is made by the lower part of the saw, it remains open, and only slightly covered by a movable guard, while the top is protected by a stationary casing. While working with the material, pressing on the canvas, the fence moves apart from the pressure, opening the disc itself. By releasing the pressure, everything returns to its place. It is very important that the mobile part works without jamming, otherwise working with such a device will be difficult.

Movable cover: features

Another one of the fuses is the clamping flanges, which are located on both sides of the disc. In the case when the working material is wedged, the flanges contribute to the sliding of the clamps, so that the engine does not overheat.

It is very important that the handle itself be of a convenient shape, easily lying in your hand, without slipping in it. Only in this case, the operator will be able to work with the tool both conveniently and safely.

To make more or less deep cuts, you just need to lift or, conversely, lower the saw blade, focusing on the supporting ski. You can navigate using the scale or on the workpiece itself. If it is necessary to saw off elements completely, then the saw should look out on 2-3 mm.

Circular saw blade application scheme.

When working with wood, there is such a feature as its tension between the fibers, which is released if the work is carried out along the fibers. This property of the material leads to the fact that very often there is a closure of the kerf behind the disk, and then the web is wedged. To avoid this, the saws are equipped with special knives behind the disk itself, which are located at a distance of 2-3 mm. For correct work, the tip of the knife should be 0.3 cm higher than the lowest tooth of the saw.

A very important point is the choice of working material. It depends on which disk will be used, because if it is ordinary wood for the fence, then you can get by with the cheapest disk. But if the quality of the web is necessary at the highest level, without any burrs, in order to minimize external defects and finishing work, you should choose a technique with high-quality discs.

If any joints are to be cut out of the material, then the canvas must be of the highest quality. Well, if the saw blade has a Teflon coating, so it reduces friction moments, then the mechanism itself will last longer. In addition, if the unit operates at high speeds, it will not “burn” the tree. There are disk options when the teeth are coated with tungsten carbide. This coating allows you to extend the life of the saw, and the work itself is performed more cleanly. If necessary, you can install discs for cutting not only wood, but also metal, plastic or stone.

Working with a circular saw

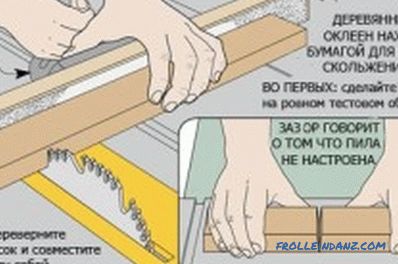

While the circular saw is in operation, its teeth move from the bottom up, therefore the blade control itself must occur from above. In order for defects to be minimally visible on the workpiece, it is best to place the wood face down. It is very important that the workpiece is firmly fixed, and the quality of work and the safety of the operator directly depend on it.

The circular saw blade has a small cutout that serves as a "sight".

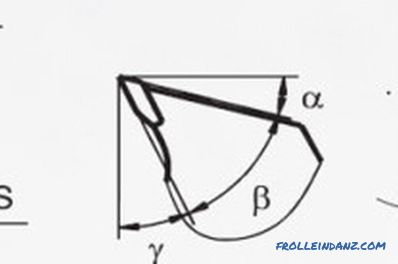

Angles of sharpening of the saw blade teeth.

Before proceeding directly to the cutting itself, it would be good to make a couple of test motions on an unnecessary tree, so that it was possible to compare the reamer and cut it.

Work can be carried out both on the markings, and using the guide line. Therefore, depending on individual skills, one or another apparatus is acquired.

It is very important that after each sawing, the saw covers its own safety fence and the disk itself comes to a standstill. Therefore, until the disk stops, it is better not to put the saw on the table.

Personal safety is also very important. First, before starting work it would be good to have safety glasses, gloves and even a respirator. The clothes themselves should also not be of light materials. And secondly, since the work is done with a tree, all hotbeds of open fire should be eliminated near.

Table for a circular saw with his own

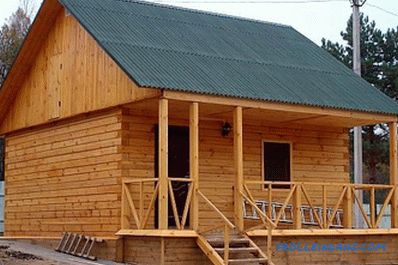

A garage is often used for home workshops. Of course, if you have your own private house, then under such a room you can allocate a whole separate room or any building located in the territory of the site.

Every man tries to adapt the workshop for himself, but this does not mean that it should not meet certain requirements.

Barrels for the circular saw.

First of all, we should talk about the availability of furniture. Working with wood and metal implies the presence of completely different tools and equipment. Even professionals have misfires when the device flies out of hand. Therefore, in order to preserve everything in integrity and safety, you need to have furniture in the workshop only the most necessary: a table, a couple of chairs, a stool, a wardrobe and shelves.

Just about the table, it's worth talking separately. Such a tool as a circular saw can not work on weight, it needs support, therefore, with the help of a special fixing mechanism, very many fasten it directly to the table surface. As a result, it is necessary to very quickly look for a new replacement for the table, and all because the usual table is not suitable for this function.

And then it is possible to resolve this issue by assembling the table yourself. The most convenient is that it will require minimal financial costs. All available material will consist of:

- wooden boards or bars;

- multilayer plywood;

- hammer;

- nails (nuts, screws) ;

- glue;

- construction level;

- measuring tape;

- chisels;

- hacksaws;

- electric drill ;

- screwdriver.

Wood can always be taken from unnecessary, broken old furniture. This way you can save money both on the base of the table and on its legs.

The main condition for this construction is the evenness of the surface.After all, the circular saw requires great precision, and if such a table is not level or loose, it can be quite unsafe.

If you have skills in the construction industry, you can create a table for individual needs. But if this question is taken for the first time, then it is best to create a structure of the simplest form.

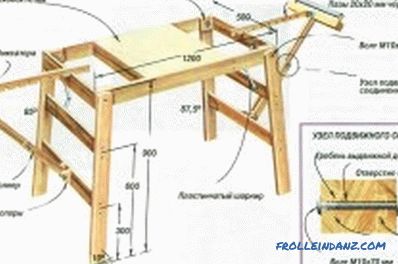

Schematic of the saw table.

Once all the tools and materials are available, you can proceed to work. All elements of the tree must be fastened together firmly and securely. For this purpose, nails are used, and for reliability, you can secure yourself with the help of bolts with nuts and screws.

First of all the base is made. This moment should be given special attention, since it is the pillar and guarantor of operator safety. The most convenient option is a pair of wooden goats. For this, wooden blocks are cut into separate parts, 0.72-0.76 m high. This is quite an acceptable height for the working surface. But this parameter can be changed, depending on the growth of the employee. In addition, with the help of wooden flooring, you can adjust the height of the table by yourself, making it higher or lower.

Next, the support elements are fastened together by means of nails (screws or screws). After that, they are engaged in installing wooden cross-beams on the upper part of the goats. The evenness of such anchorages must be monitored with a building level. For your own convenience, it would be better if such a table is collapsible, so that if necessary it can be disassembled and removed somewhere for storage.

Multi-plywood will serve as the working surface of the table. It is best if such material is not thinner than 2 cm, and its surface must be perfectly flat, without any irregularities or bends. The optimal size of the working surface is 65x90 cm. Two bars are fixed along the length of the table, and four - in width. All fastening occurs with the help of nails (screws, screws).

Since the table is designed for a circular saw, it is necessary to take care of the hole for it. It is desirable that it is in the center of the table. The standard width of such a slot will be 2 cm, taking into account the protective casing. Excess length will vary between 25-30 mm, depending on the diameter of the saw blade. On the underside of the surface with power clamps attached electric saws. In this case, it is recommended to use countersunk screws. At this stage it is very important that the saw blade in the on state has a parallel rotation of the slot.

Conclusion and debriefing

At the end of the table assembly, it is necessary to sand all the burrs on the tree. Firstly, it will give a finished look to the product, and secondly, there will be no risk of hooking clothes on the table or simply driving a splinter into your finger.

Of course, if there is a possibility, then such a table can be built from metal plates. It will last much longer.

The hand-held circular saw is a very convenient tool for household use, but here in the set with the table its functional range will significantly expand. And after all, the main thing that is worth noting is that if you have a table under the saw blade while working on it, the physical strength costs are much less, which means you can do more work without being too tired.