Log building construction is gaining more and more popularity. Such houses have a special comfort and create a sense of naturalness and closeness to nature. However, when constructing a wooden building, it is necessary to take into account the peculiarities of the material and to observe the technological features of the construction. One of the obligatory processes is a log felling with his own hands.

Thermal insulation by a caulk of a wooden house is done by caulking the gaps between the logs inside and outside the house.

A caulk of a log house is necessary to eliminate the gaps between the individual elements. In the absence of gaps between the logs, cold does not penetrate the house from the street.

Methods for caulking of a log house with their own hands

The quality of the result when independently performing cauldron is largely dependent on the materials and tools used. In addition, it is very important to observe the technological details of the process for optimal results.

You will need tools to work:

- Hammer. Its weight should be in the range of 300-400 g.

- Chisel 2 cm.

- Special blade for the caulker.

- Kiyanka of rubber.

Tools for the frets.

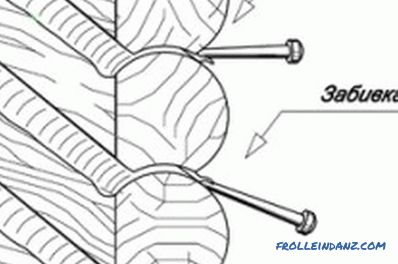

It is best to caulk a house 6 months after construction. A year later, the procedure is repeated, as the house sits down. If necessary, you can repeat the caulker 5 years after construction. You can perform a log caulk with a perforator instead of a hammer. However, in this case it is necessary to observe heightened caution and care, as it is possible to significantly damage the logs.

To fill the gaps between the logs, one of two ways can be used:

- in stretching;

- in the set.

In the first case, the material is placed in separate strands. The gap is filled, strands twisted into a roller, which is driven into the groove. If the caulker is in the set, the insulation will be divided into strands that fold into a ball. Formed from strands, a ball is filled with cracks. The amount of material driven in depends on the width of the slit. Due to the peculiarities of caulking technology, it is also called punching.

Materials used

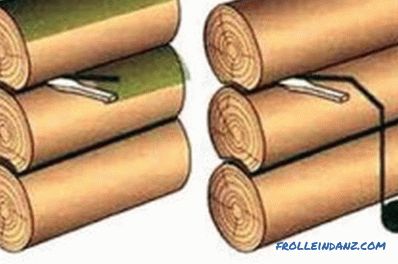

As a rule, natural materials are used to warm the walls of a log house. Traditional options:

- moss;

- hemp;

- flax;

- tow;

- felt.

Caulking Technology.

Natural insulation is environmentally friendly, this explains their popularity. However, they also have certain disadvantages - low hygroscopicity and short service life. In addition, such insulation attract insects that can spoil not only them, but also wood.

Popularity is gaining modern material - jute fiber. Its advantage over alternative options is hygroscopicity and strength. However, jute felt - this is not the best solution for the roaster. The composition of the material includes flax. Felt of jute quickly rot, it starts the mole, and its strength is insufficient for the goals.

It is worth paying attention to lnovatin. In its production using industrial waste flax. The material has high rigidity and strength.

Peculiarities of caulk

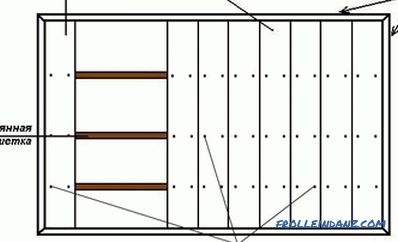

Scheme of caulk methods.

A frame is a special type of construction, any manipulation of which can greatly affect its parameters. Caulk walls must be in a circle, starting from the bottom row. You can not first handle one wall, and then move on to another, because in this case the frame can be skewed.

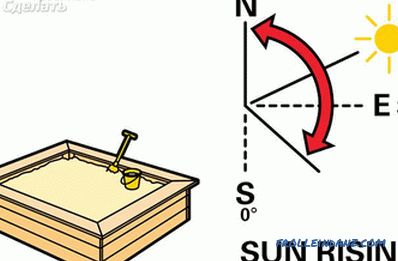

Peculiarities of the caulker must be considered even at the stage of the construction of the log house. So, when laying insulation material it is very important to leave a gap of 4-5 cm. With a caulker, this will simplify the work. Laying the material in the grooves will have later, if you do not provide for a small gap. As a result, the quality of insulation will be significantly reduced.

The first caulker is made 6 months after laying the bar.

This period allows the house to settle. There are noticeable shortcomings of styling, which can be partially corrected or disguised with a caulk. Before construction and re-caulking it is necessary to take into account that a caulker made in accordance with the technology increases the height of the house by about 15 cm. Filling each seam must be done carefully, avoiding gaps.

Thus, you can do it yourself. It is very important to prepare high-quality materials and special tools. Proper filling of the joints between the elements of the framework allows to significantly enhance its thermal insulation.

Didn't find the answer in the article? More information on the topic:

-

How to dry the tree properly?

Recommendations on how to dry the tree yourself.Rules for proper drying of wood. Drying under atmospheric conditions. Advice of experts on drying wood.

-

Processing of wooden floors

Processing wooden floors: how to save the flooring. Varnish, wax, oil, advantages and disadvantages of materials. All the secrets of wood flooring tools.