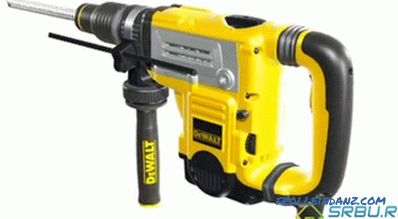

When a house is being renovated or a house is being built, a puncher is one of the most necessary tools. With the advent of this device, capable of withstanding substantial loads, work has become easier and more comfortable. The choice of such devices today is huge - they are offered by each manufacturer of the tool.

But how to choose a punch that will be of high quality, convenient and will last for a long time. Such a question is fully justified - after all, when buying, you will have to spend a rather large amount - it is impossible to call this pleasure too cheap. To make the right choice, you need to know the principle of the punch and the features of its design. Consider all this in detail to find out how different models of similar devices differ from each other.

A hammer drill and a hammer drill are not the same thing

Some people mistakenly believe that a hammer drill with hammer drill works in exactly the same way as a hammer drill. But this is not so - although they call such a drill a “drill-perforator”, but the principle of operation of these two electric tools is strikingly different. Yes, they both pierce the holes, but the blows at the same time have different strengths, as well as different origins.

The hammer type drill works as a punch by gearing two wheels, called ratchets. With a certain pressure on the drill, an oscillatory movement of its axis occurs, which allows you to make a hole. But the performance can not be high, and the blows are pretty weak. Therefore, solid concrete, for example, cannot be punched with such a drill.

But the perforator is precisely designed for drilling stone, brick and concrete. It can also be used to transfer the force to the working edge of a spike, paddle or drill, allowing these tools to work with maximum efficiency.

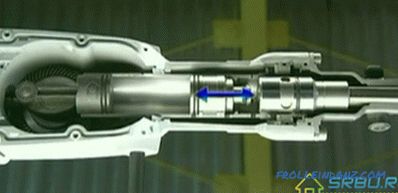

In the perforator, an electromechanical or electro-pneumatic type mechanism is used as the main structural element. Thanks to it, a shock force is created that is sufficient to penetrate concrete or stone. In this case, the master does not need to push much on the punch handle. In some models, the mechanical impact mechanism is similar to that of a drill, but it is less durable than an electromagnetic or pneumatic mechanism.

The piston and the mechanism of the pneumatic system of impacts, as a rule, they are equipped with L-shaped drills.

A drunken-bearing mechanism that rotates the firing pin to make strikes; narrow punchers are equipped with such a mechanism.

So, if we compare the mechanical and pneumatic mechanisms, we can see that the latter greatly facilitates the work on a solid surface. When using a mechanical percussion device, it is necessary to apply a force three times greater than when using a pneumatic device. Therefore, deciding how to choose a punch for the house, it is better to turn your eyes in the direction of more modern models, and forget about the mechanical ones safely.

- See the material. . Difference of the perforator from the hammer drill - we’ll sort everything out

What should be considered when choosing a perforator

This tool can be: with one drilling mode, with two modes (drilling plus blow), and also with three modes (slotting is added to the previous two modes). In addition, weight drills are classified into heavy, medium weight and light. The latter will not be heavier than 4 kilograms, the average will “pull” from 4 to 5 kilograms, and the heaviest instruments of this type can weigh 5-10 kilograms or more.

Impact energy

One of the main parameters of the device is the impact energy. To measure it, joules are used. Lightweight models have a strike force of no more than 1-2 joules, and punch "more serious" can hit with a force of 8 to 15 joules. The higher the impact energy, the larger the hole diameter can be obtained. When this value is small enough, the device does not work more efficiently than a hammer drill. However, he will not pierce the hole, and drill it. As a result, its equipment will wear out extremely quickly, and you will not have to dream of high performance.

Speaking of the impact energy, one should know that it does not depend on the force with which to press the punch handle. But when working with a hammer drill, the situation is just the opposite. If the adventurous seller of an instrument store to attract attention tells about the increased energy of the blow of a punch, listen to his words with skepticism. You should know that the value of this parameter in excess of 10 joules, will lead to a rapid failure of your instrument. After all, with such high loads, its refractory inserts will collapse in a very short period of time.

Frequency of strikes

If you count how many times in one minute the device's piston strikes a striker head, we get a value called the frequency of strikes. The larger it is, the higher the speed of punching holes.The perforator's performance depends on both the frequency and the impact energy. Manufacturers that produce the most durable and efficient devices in their models harmoniously combine these two parameters. Therefore, wondering how to choose a punch, it is better to pay your attention to reliable brands whose products are of excellent quality and amazing durability. Specifically, we will talk about the best manufacturing companies a little further.

Power punch

Punchers are less powerful devices than electric drills. This is due to the fact that drilling is much harder than drilling. Therefore, the punch shaft does not require such a high rotational speed during operation as the drill has. Devices with different types of cartridges power is different. From 400 to 800 watts consume models with cartridges type SDS-Plus. Perforators with SDS-Max cartridges have a capacity ranging from 1 to 1.2 kilowatts. As a matter of fact, choosing this tool, one should not emphasize power - this is not the most important parameter.

Spindle speed

The speed of rotation of the punch shaft is lower than that of the drill - this was mentioned above. Depending on the class of the device, the value of this value can range from 600 to 1500 revolutions per minute. The rotation frequency decreases with increasing power and productivity of the perforator - this is due to its structural features. After all, for productive models, the optimum tooling diameter is large enough. In general, the shaft of the device rotates only to remove the dust after drilling. The little boer has to rotate faster, and the big one has to go slower, otherwise it will wear out too quickly.

Models of punchers with a high speed of rotation of a shaft have a considerable weight that does not facilitate usability. In addition, these high-speed devices very quickly wear spiral grooves, with which drilling waste is removed from the workplace. Because of this, the device starts to get very hot, and as a result, it may even stick in the hole.

Type of chuck mounting holder

When discussing with a friend what punch is better, the home master does not always take into account one important parameter. This is a method of fastening a drill, of which there are currently three.

If a small device weighing up to 4 kilograms is required, it is better to choose a model with the SDS plus fastening system. Holes such a device can do with a diameter of not more than 3 centimeters. Usually this is quite enough for domestic needs, and such punchers are most demanded by buyers.

Professional models, which sometimes weigh up to 11 kilograms, are equipped with the SDS max-type drill fastening system. These devices are quite large in size. However, they are also able to pierce holes rather big - up to 5.2 centimeters.

Two mounting types, on the left SDS Plus, on the right SDS Max.

Recently, another type of attachment has been used - SDS-top. It is well suited for the manufacture of holes with a diameter of 1.6 to 2.5 centimeters. This mount is often used in devices manufactured by Bosch.

Modes of operation of the punch

Now let's take a closer look at how the punchers differ from each other with a different number of modes of operation. So:

The simplest instruments are single-mode. They work the same way as an ordinary drill. If you have to drill wooden and metal surfaces, they are quite suitable.

With a dual-mode device, the axis can not only rotate, but also oscillate during rotation.

The three-mode punch as an additional function has the ability to strike without spindle rotation. Such a device is the most versatile, it can just drill, drill and chisel and just chisel.

The variety of perforator models suggests that each of them may have different modifications. However, they can be performed with one, or with two or three modes of operation. If we talk about the latter option, then it costs more, of course. But on the other hand, such a device will help a lot, if you have to choose a punch to work both in drilling, drilling and crushing, then you definitely need to stop at a three-mode device.

When choosing a device, its shape and design play an important role. Holding the device in your hand, you need to feel that it will be convenient to work with it. In this case, pay attention to whether there are side handles that can be easily removed - great, if such an option is provided. It will help if you have to drill in a tight corner, for example. Removed the handle - and work with all the amenities.

Punch shape

Punch shape can be either straight or L-shaped. The latter engine is located vertically, so that the device is more compact.In addition, the engine cooling is arranged quite effectively. Such devices can work for a long time without overheating, and they serve a lot. That's just the weight they have very noticeable.

L-shaped perforator, the engine is located vertically.

Narrow and long drills of the direct type weigh less, and due to their design they will creep into any slot. The engine is placed in them horizontally.

A narrow, long punch, the engine is horizontal.

The following functions can be built into the punch:

- The depth gauge helps you know if the drill has reached the desired mark.

- The gearshift mechanism is useful when you need to switch from a drill to a drill or vice versa. After all, they must move at different speeds.

- Reverse rotation of the shaft will help when the drill bit gets stuck in any surface.

- A soft start and a device that protects against overheating will help to avoid trouble, promising a breakdown of the device.

- Stabilization of the shaft speed during load force fluctuations is a very useful function.

Additional Functions

When thinking about how to choose a good punch, we hope that there will be all sorts of convenient additions.

1. For example, dust protection doesn’t hurt at all - hardly anyone has to work under sterile conditions.

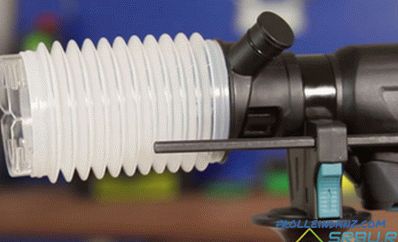

Device for protection against dust during drilling.

2. No less convenient is the anti-vibration system, which softens and compensates for the shaking of the device when drilling, chiseling or drilling.

Vibration protection system.

3. Another useful "chip" is the locking button, which fixes the punch in the working mode.

True, each of the additional features does not make the device cheaper, so choose only what you really need. You should not overpay for the functions that you never use in the future.

Completion of the perforator

And now let's talk about the configuration of the perforator - the more complete it is, the fewer tools you will have to buy later. So, what should be in the case with the device:

1. Spare brushes for electric motor.

2. A special chuck, which is an adapter, will help you use conventional drills for drills, rather than fast-tightening drills. After all, punch drills are more expensive, and in the absence of such a cartridge will have to spend considerably.

3. Boers - basic kit. For domestic needs it is more than enough, but professional models need a more impressive kit.

Manufacturer

Now let's talk a little about which firm to choose a punch. The most reliable brands that almost everyone has probably heard about are BOSCH and MAKITA. It is in their direction that you have to take a look, choosing a professional punch model. And for a house, besides these two firms, it is also possible to advise the following manufacturers of WATT, STERN, EINHELL, VT.

And yet: a household model or a professional one?

More expensive and powerful professional appliances are equipped with many functions. They are reliable and durable. It is easy to distinguish them: usually, for all manufacturers, models for professional use are painted in a different color than household ones. Yes, and the inscriptions corresponding to them are available. But the most important difference between them is the time of continuous work, which lasts for 7 - 8 hours, that is, the whole working day. However, why is a heavy and cumbersome device for the "pros" at home? As a rule, it is not necessary to carry out super-tasks, and for the most ordinary repair or hanging of shelves, the middle class model is quite enough.

Let's list the optimal characteristics of a punch that you plan to use for household needs. With similar parameters, you can easily and quickly drill holes in concrete with a diameter of 1.6 to 2.8 centimeters, as well as perform other types of work. So, a good punch has the following parameters:

- Power - from 0.5 to 0.9 kilowatts.

- The impact force ranges from 1.2 to 2.2 joules.

- Operating modes - three (except for drilling, also slotting and drilling).

- Adjust the speed of rotation of the shaft.

- There must be a safety clutch - it will protect the device from jamming.

- The drill should be secured with the SDS plus system - no need to use keys to clamp or unclamp the chuck.

Next, see for yourself - hold the tool in your hands, try to make a test hole. If you feel that it will be convenient to work, take it. In general, the answer to the question, which punch is better to choose, is obvious. Of course, the one that will be most suitable for your tasks. Just keep in mind that when performing these tasks, the device must be handled carefully. About this below.

Properly exploiting a punch

These few simple rules will help your lovingly chosen tool last for a long time, avoiding annoying breakdowns.

So:

- It is advisable to use only the "native" cartridges, drills and lubricants that are provided by the manufacturer.

- Maintenance, cleaning and lubrication are recommended regularly. Especially pay attention to the lubrication of the SDS shank of the tool for work.

- You should not work with the device for a long time without stopping. It is necessary to periodically give him time to cool.

- When drilling a deep hole, work must be done in several stages, each time pulling out the drill and thus cleaning the hole. This will occur through the disposal of drilling waste.

- If you press on a tool, the impact mechanism will wear out before time. It is also fraught with overheating of the engine armature.

- Use the slotting mode for a short time - mix it with the rotational mode, at least for 2 minutes. This will cool the device, and also allow the lubricant to be evenly distributed in the right places. Thus, the forced lubrication system will work.

- In order not to break the chuck, it is necessary to work strictly perpendicular to the axis of the hole being punched, avoiding distortions of the tool.

- The boot and brushes of the electric motor should be periodically inspected, put in order and replaced if necessary.

- You should not wait until a small malfunction turns into a major breakdown. It is better to immediately contact the service center - so it will be much cheaper.

Thus, we believe that the answer to the question of how to choose the right punch, you got from this article.

Video: Punch selection