For the construction of a residential house, the most commonly considered options are wooden construction. Widespread timber. Its use allows you to facilitate the process of construction of the log house

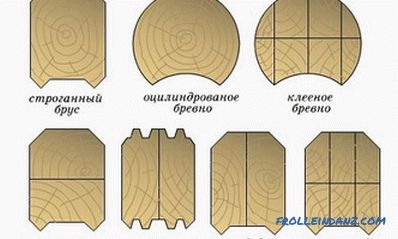

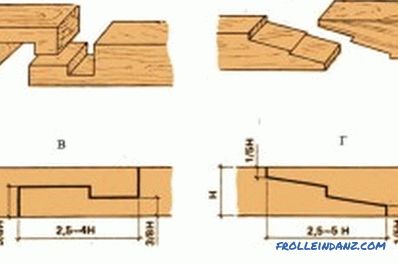

Types of profiled timber.

The technology for assembling a house from a bar can be quite different depending on which profile has the building material.

Features, Required Tools

There are several types used:

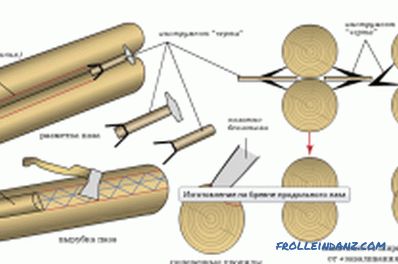

Log preparation scheme for log house assembly.

- Construction - sawn, or, as it is also sometimes called, "shaggy" timber. In cross section it is a square or rectangle.

- Profiled timber - differs from construction by

The design of the mating line involves laying a layer of insulation. Sometimes mating is carried out without the use of auxiliary materials, which is called dry.

Manufacturers profiled b The mustache can be produced in two varieties:

- whole - made of a single solid wood;

- glued - during production gluing of individual lamellae is carried out.

at home, regardless of the profile used, you will need the minimum required set of tools:

- saw;

- drill;

- hydraulic or laser level;

- stapler construction;

- sledgehammer.

In addition to the tools listed above, auxiliary materials are required:

- mezhventsovy heater;

- wooden n gels;

- if necessary metal stud diameter not less M12.

Technology to tie the laminated timber with pins.

When building a log house from a profiled bar, most often at the factory, according to the project, a house set is prepared. The output is actually a set-designer, where every detail is numbered. Using the attached design drawings, with at least minimal experience with the tool, it is relatively easy to assemble the entire structure on site.

The basic rule for storing building materials on the site is protection from the effects of precipitation and moisture ingress from the soil. Therefore, it is best to organize a temporary storage place under a canopy. To prevent the ingress of soil moisture, all parts are placed on temporary supports. The distance to the ground level should be at least 20-30 cm.

Practical recommendations

The process of assembling a log-like log house is similar to the assembly of a log house from a conventional log. The foundation is laid waterproofing in 3-4 layers. On top of the waterproofing set the mortgage board and ram crown.

Here the important point that determines the quality of the entire subsequent assembly is the installation of the entire crown on exactly the same level. No matter how well and precisely the foundation was made, differences in height can occur, sometimes very significant. These drops can be eliminated by placing control pads and checking their position with a level. Another way to adjust the base is to shake the baseboard until a horizontal surface is obtained.

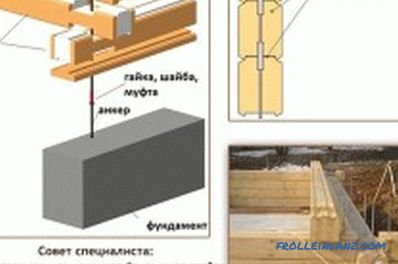

To continue the assembly process, the corners are rigidly fixed with building brackets, after a certain distance (1.5-2 m), but not less than two points on the wall, fixed to the foundation with metal anchors.

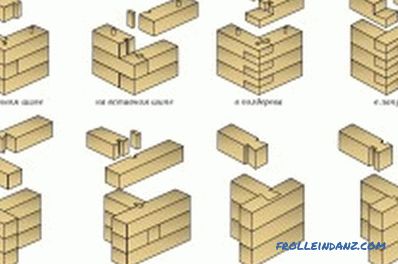

Methods for joining timber without residue.

An interlock seal is placed in the lock joint and on the entire surface of the beam. To prevent displacement during installation work, it is fixed with a stapler.

The construction of the walls of the house from the timber is carried out by sequential laying of the crowns in a predetermined order. To stiffen the structure and prevent deformations in the future, at certain intervals (1-1.5 m), holes are drilled into which pins of hard wood (usually birch are used) are placed in the sledge with a sledge hammer. The length of the dowel should be sufficient to pass through 2, maximum 3 crowns. At the same time, its length should be several centimeters less than the depth of the mounting hole.

A felling can be made even more rigid by additionally fastening the crowns between each other with screw pins.

The tie stud is carried out at once of all the crowns. Studs are installed in places of overlaps, along windows and doorways. If the walls are long, the spike installation interval is approximately 2 m.

The sequence for assembling walls from a timber in this case is as follows:

The length of the beam connection direct patch lock and oblique patch lock.

- in the adjacent rims the holes of slightly larger diameter than the stud are pre-drilled;

- the sufficient depth of the grooves for the installation of nuts and washers are selected;

- the stud with nuts are fixed in the drilled hole of the lower rim;

- putting the bar on the studs;

- fitting to the landing sites and checking the level of horizontal installation;

- fixing the installed bar by tightening the nuts on the studs while knocking a beam with a sledgehammer through a baseboard;

- checking horizontal position b mustache and adjustment are tightened if necessary.

Sometimes, instead of studs, self-tapping screws with a socket head are used, tightening two adjacent crowns. The installation of self-tapping screws is carried out at the intersections of the bars and at intervals of 1-1.5 m. However, this version of the screed, although easier to perform, has less resistance to deformation.

The combined method of using studs and dowels allows you to prevent deformations of the wall in the vertical and horizontal directions, respectively.

Additional points

Construction of a wall from a bar.

When building a sawn timber, the analogies with a log are even more. Here the corners of the log can be collected both in the paw and in the bowl. The hemming of the internal walls, beams and floor lags is made by a frying pan (visually this connection is similar to the dovetail connection).

It is obligatory in this case to fasten the rims with the help of dowels (spikes) and studs. This also affects the partitions, since they must be reinforced as much as possible not only by the structure itself, but also by themselves.

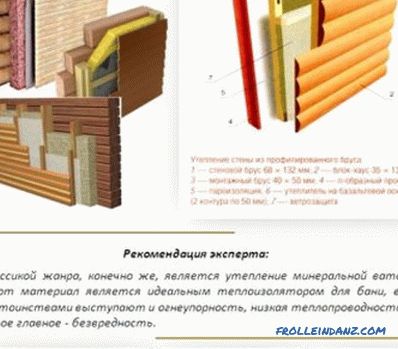

To ensure thermal insulation and tight connection of adjacent rims, a layer of insulation is laid on the entire surface of the beam.

When building from such a material, the walls give inevitable shrinkage. And periodically it is necessary to tighten the nuts on the heels.

Regardless of the type of material used, a number of rules must be strictly observed when building a house from a bar:

- During the installation, each beam must be installed in its place and fixed on it with the help of hardware design features or accessories. It is necessary to strive for the highest possible installation accuracy.

- All fixing structures must necessarily provide free shrinkage of the walls of the house and prevent changes in the geometric parameters of the timber.

- All work related to the installation of dowels should be carried out after fixing the beam.

- Holes for dowels must be made strictly vertically. This is possible when using rack conductors for drilling.

- The use of screw ties is extremely desirable. This will avoid deformations in the vertical direction.

- After the assembly process is completed, the interlock seams should be sealed using a natural seal or protected with a special sealant.

Compliance with the listed rules allows you to get a reliable warm home that you will not have to periodically patch and repair and which you can be proud of.

Didn't find the answer in the article? More information on the topic:

-

How to properly heat a log house

Instructions and detailed description of the process: how to insulate a log house. Practical recommendations. The device ventilated facade technology log house insulation.

-

How is it better to level the wooden floor?

How can you level the wooden floor: methods. Determination of the state of the wooden floor. Wet screed, sanding, putty and PVA glue, using plywood to level the floor.