A massive board is a topcoat that is made from a solid solid wood of softwood or hardwood. A floor decorated with such material will have a beautiful appearance, good thermal insulation and increased resistance to mechanical stress.

The massive board is made of various breeds of wood and intended for finishing of a floor.

If the installation of solid wood is done with strict observance of all the rules and recommendations, then this flooring will serve more than one generation.

Preparatory work

Before laying the massive board, it is necessary to choose and prepare the finishing material itself. A massive board is considered qualitative if it has the following technical characteristics:

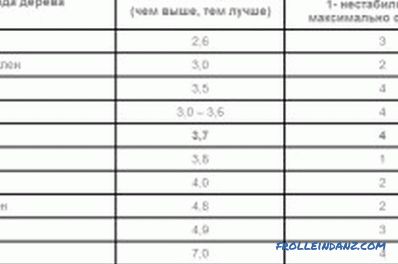

Comparative table of characteristics of a solid board depending on the type of wood.

- length - 0.5-3 m;

- width - 10-15 cm;

- thickness - 15-30 mm, and sometimes 60 mm;

- humidity - 6-10%;

- dimensional tolerances - less than 0.5 mm.

The strength characteristics of the future foundation directly depend on the thickness of the finishing material. The most popular is the board thickness of 20-25 mm, but the final choice will depend on the type of wood, the type of substrate and the conditions of its operation.

After purchasing the boards, they should be carefully examined for various defects, and then sorted by color and pattern. Next, you need to determine which boards will be used whole and which ones will be used for trimming. The sorted material must be left in the room where it will fit, for 3-7 days. This is done so that the wood acclimatizes to the conditions in which it will be used. In this case, the boards after installation will not swell or shrink.

The base of the floor to be laid should be dry and level. A deviation in height of not more than 2 mm per 1 running meter is allowed. If this condition is neglected, then after a while the boards will start to creak, and the floorboards will move, which will bring you a lot of inconvenience and noticeable discomfort.

Types of floor leveling.

In preparing the base, alignment methods are used:

- plywood;

- lags;

- concrete screed.

You should also ensure that the subfloor is durable, reliable and free from debris. In the presence of rotten areas, the wood from them is removed and replaced with a new one. Immediately before laying the solid board it is necessary:

- to turn on all heating systems and air conditioning devices so that the temperature in the room reaches 19-23 ° C and remains constant throughout the week after the installation;

- achieve air humidity of about 44-54% and maintain it throughout the installation work;

- achieve a moisture content of the subfloor at 13% and a difference in moisture content of solid wood and base not more than 4%.

Methods for laying solid wood boards

For installation work, you may need tools and materials such as:

Tools for stacking solid wood.

- jigsaw or circular saw;

- screwdriver;

- belt grinder;

- vacuum cleaner;

- level ;

- tape measure;

- square;

- hammer;

- spatula;

- pencil;

- leveling mix concrete base;

- parquet glue;

- plywood;

- waterproofing material;

- fasteners.

Depending on the design features of the base, there are such methods of mounting a solid board:

- on a wooden floor;

- on a concrete base on plywood or logs;

- on bearing wooden structures.

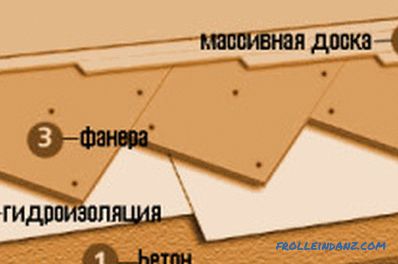

The first method of laying can be used only if you are completely sure that the old wooden flooring will support the additional weight of the parquet. First of all, with the help of a sander, the old base is thoroughly polished, after which, if necessary, a layer of waterproofing material is laid. At the last stage of work, the massive board is directly mounted, which is made in the same direction in which the old coating was laid.

In the second case, plywood or logs are installed first. If it is supposed to use a log, then they are fixed to the concrete base with the help of screws or dowels.

Lags are stacked in a direction perpendicular to the future coating in increments of about 25-35 cm.

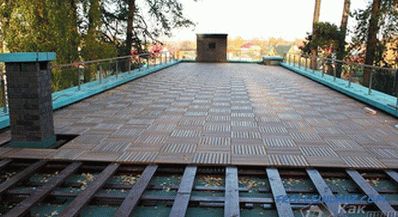

Laying solid wood on concrete.

At the same time, their horizontal evenness is constantly monitored with the help of a building level. In between the lags fit insulation and waterproofing material. On top of the laid logs, a massive board is being assembled.

If you use plywood, you first need to cut it into strips about 50 cm wide, then lay it on a concrete base diagonally to a future overlap and attach it with screws or dowels.

Installation on bearing wooden structures is used when the base for the parquet is plywood or boardwalk. In this case, logs are also used, over which waterproofing material and plywood are laid. Plywood is attached to the logs with screws, the heads of which are inserted into the base. After careful processing of plywood with a grinder, a massive board is laid.

Technology of laying solid wood boards

If the basis for the installation work is prepared taking into account all the requirements and recommendations, the process of laying a massive board will pass easily and quickly. Usually the board is mounted parallel to the window opening, but you can use any other styling options.

Installation of the first row of parquet is carried out along the longest wall with a spike to it. Boards are aligned and fixed to the base with self-tapping screws so that their heads can be closed with a plinth. The opposite side is also fixed with self-tapping screws, only in this case they should be screwed at an angle of 45 ° to the floor. Screws for wood, which are 2-3 times longer than the thickness of the parquet, are perfect for this purpose.

All subsequent rows are stacked into the groove of the previous row and fixed in the same way using self-tapping screws. To maximize the fit of the boards between them, they must be adjusted using pads. The last row is fixed in the same way as the first one, so that the screws can be hidden under the baseboard.

Didn't find the answer in the article? More information on the topic:

-

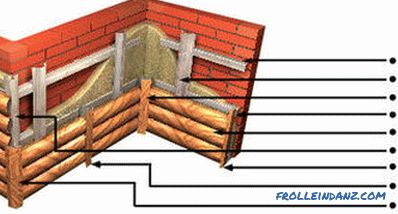

Decorating the walls of the house with a tree outside

Decorating the house with a tree outside with your own hands. The main advantages and disadvantages of using wood for building cladding. Decorating the house with wood panels and block house.