Joints, seams of any structures are the most vulnerable places. The same can be said about the windows installed in the window opening. It is the assembly seam that will be the weakest point in the whole structure. Through poorly laid seam can leave the heat, penetrate moisture and other sounds from the street, finally, the condensate that forms when the temperature difference will accumulate inside the insulation and degrade its characteristics, leading to destruction. The description of the characteristics of the installation seam and its installation technology is given special attention in GOST. At the moment, GOST 30971-2012 is valid.

Technology features. Why do I need a vapor barrier tape

According to GOST, the installation seam must be three-layered. Each layer performs its function:

- The middle layer - the main one - provides heat and sound insulation due to its porous structure.

- The outer layer protects from moisture coming from the street (he removes it) and from UV rays.

- Inner layer - vapor barrier. In fact, it retains heat in the house and does not allow a couple accumulating in the inner space of the room to penetrate inside the insulation layer.

Scheme of the device of the installation seam

Scheme of the device of the installation seam

Thus, compliance with the technology of the device of the seam is necessary Prevent moisture penetration, condensation, improve heat and sound insulation properties. Failure to install insulation layers will reduce the cost of installation and construction by about 15-20%, in general, but GOST does not allow such cases.

Classification of vapor barriers for windows

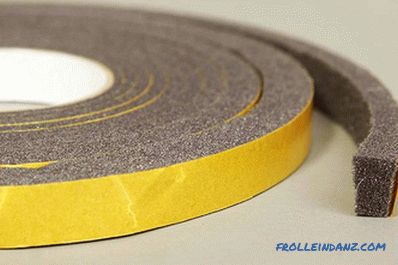

For the installation of a PVC window a vapor barrier is used in all varieties of varieties and vapor-permeable diffusion tape.

Tapes can have one or two adhesive surfaces. The first ones are installed on the frame itself, the second ones can be installed in the window opening, gluing them both to the wall and to the window profile. The range is divided into winter and summer options. Summer is designed to be installed at temperatures from +5 degrees to +35 degrees, winter - for installation at temperatures of +5 degrees and below. Moreover, when installing in winter, the surface of the window opening is required.

The tape should be about 5 cm more than the width of the installation seam.

Two types of tapes are distinguished by the production material:

- Butyl rubber tape with a non-woven reinforcing layer designed to seal joints.

- Metallized tape designed for installation in wet areas.

Types of tapes

The functionality of tapes is different, so when installing a window, different types are used depending on the goals at each particular stage. You should review the tapes.

| Material of production | Where | Properties | Features | |

| | Polyurethane | Used when organizing a ventilated mounting seam on the outside. Allows you to properly close the joints. Performs as soundproofing when gluing to the bottom surface of the reflux. | Provides a tight fit of the frame to the wall. | It is necessary to unwind the tape (it is delivered twisted into rollers) just before installation. Over time, it expands and loses its sealing properties. The width of the tape PSUL should exceed the width of the mounting gap. |

| Sun (BC +) | Nonwoven fabric. BC + - foil. | Used when mounting internal slopes. It is combined with plastic, drywall, protects against condensation. | Prevents dampening of insulation used for warming slopes, in particular mineral wool. BC + has a sticky double-sided layer. It is effective steam and heat insulation | There is an adhesive layer over the entire width. Sun + thicker than Sun. |

| BM (BM +) | Nonwoven fabric. BM + - foil. | Used in the finishing of internal slopes, but under the plaster. | Prevents condensate from entering the mineral wool insulation. VM + has an adhesive layer on both sides. | Provides adhesion with plaster. BM + is more resistant to moisture. |

| GPL | Made of polyethylene foam that is laminated on one side metallized film. On the other hand, a glue layer is applied. | Universal Ribbon. Used for heat, hydro- and vapor barrier. | Combines the properties of multiple tapes. It has increased elasticity, mechanical strength and resistance to aggressive chemicals. | It can badly stick to gas and foam concrete. |

| GPL + | A thicker layer of foamed polyethylene is used than GPL . Metallized layer based on polyurethane film. | Universal Ribbon. Used for heat, hydro- and vapor barrier. | The difference from the GPL tape is that there is an additional adhesive strip on the side of the metallized film. The tape has the best thermal insulation characteristics. Effectively reflects heat. | Sufficiently voluminous, which is inconvenient when finishing slopes. |

| Diffusion tape | Polyester fabric with self-adhesive strips based on butyl rubber. | Used to seal the assembly seam from the outflow side. | It is vapor permeable from the inside, it has waterproofing properties from the outside. | Resistant to UV rays. |

| Butyl rubber mounting tape | Butyl rubber | Installed between the window sill and insulation. | Protects against blowing. | There is a self-adhesive layer. |

Installation procedure for the vapor barrier tape

The vapor barrier tape is installed after performing the preparatory procedures: dismantling the old window, cleaning the opening from debris, dust, embedding and leveling large irregularities.

- The window opening is wiped with a dry cloth and the window structure is pre-installed. In the process marks the future location of the vapor barrier tape PSUL.

- The window is removed from the window opening and glued to the frame a vapor barrier tape with an indent from the marking of 5 mm. In the corners, glue the tape butt-in, for which the ribbon with an allowance is initially cut off, which will go to fit. The surface must be degreased and dust-free.

- On the side profiles and top stick tape for slopes. leave an overlap of about 10 cm.

- Set the window. Foamed seam.

- The mounting joint on the outside is covered with a diffusion tape.

- Before installing the casting on its lower surface along the glue PSUL.

- A metallized vapor barrier tape is attached to the seam in the lower part of the window from the inside.

- The tape on the sill is glued last.

PSUL

PSUL