If you decide to make scaffolding, then you have to choose from two materials: wood or metal. In the first case, you will have a disposable design that can be made by any person who can work with wood, and in the second - reusable, but also quite easily manufactured. In this article we will explain how to make scaffolding with your own hands from metal (shaped pipe), as well as from wood (boards), we will show diagrams, photo and video instructions.

Types of scaffolding

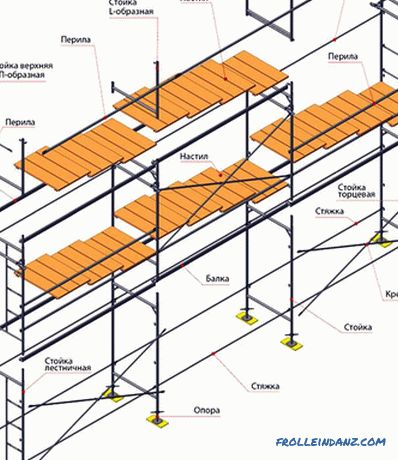

Although for the manufacture of scaffolding metal or wood is mainly used, they may differ in the method of fastening, and therefore have different functional elements in their construction. So, consider the main types of forests.

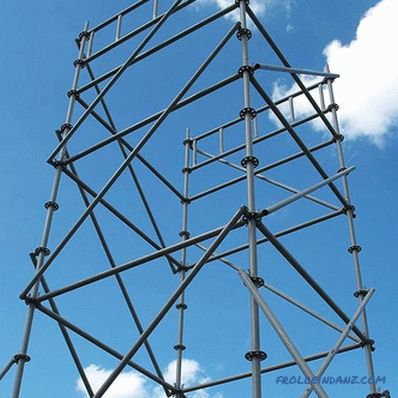

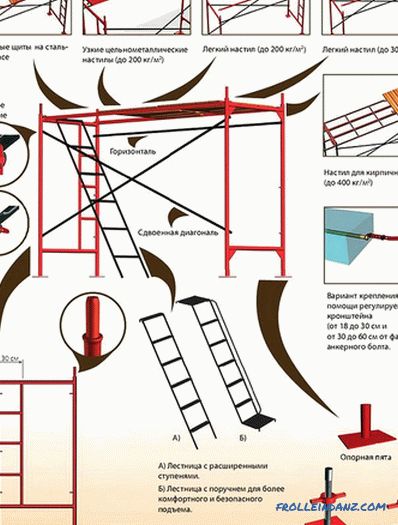

Wedge

Components are connected by a special wedge fixation. The forests of this design are highly reliable. They are able to withstand quite large loads. At the same time they are convenient in operation, they are quickly assembled and disassembled. Particularly relevant use of wedge forests in the construction and lifting of heavy materials and components.

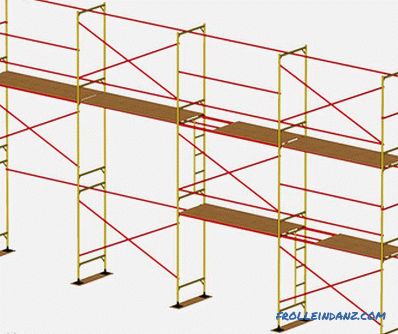

Frame

The main element of this design is a fixed frame. Mostly they are used for painting or plastering. The frame in this design is associated with horizontal racks and diagonal connections due to the nodal connections. The main advantage of frame forests in their low cost. For their construction does not require large investments.

Pin

In these forests the junction, as the name implies, is the pin. This type of forest is very popular with builders, as it is very easy to assemble and disassemble them directly on the construction site. Often, the assembly of forests takes a day, or even two. In this case, the assembly of whip woods does not take much time.

Clamp

If the object on which the repair work is carried out has a complex configuration, clapwood forests are an excellent solution. The mounting method used is professional. And for their manufacture an important role is played by the height and size of the working area, the distance between the tiers and the pitch of the racks. All this is selected individually at each facility.

From boards

We suggest you to get acquainted with a simple guide to making scaffolding from boards. To do this, follow a few simple sequential steps:

- Parallel to each other on a flat platform lay out 4 racks or boards. Their size should immediately correspond to the height of the forest.

- You will connect the racks with each other with horizontal jumpers on which the flooring will be laid later.

- Make the 2 frames horizontally opposite each other, tie them diagonally and horizontally with boards that will serve as screeds.

- You lay the flooring of the planks on the horizontal ties and attach it to the lintels with self-tapping screws.

- Attach the railing to the racks and fix the stairs.

If necessary, lengthen the construction of the scaffolding; connect several similar sections from the boards between them. The boards are stuffed on the support legs.

When assembling wooden scaffolding, if nails are used, it is recommended to pre-drill holes so that the boards do not split.

Construction

Construction of scaffolding

Construction of scaffolding

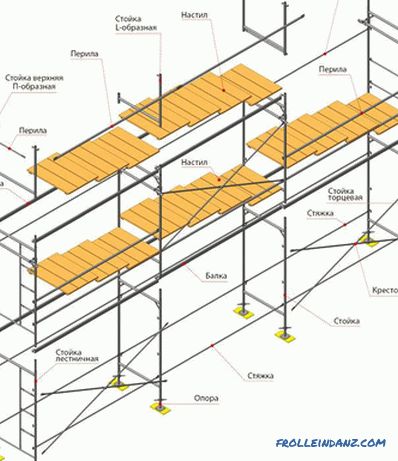

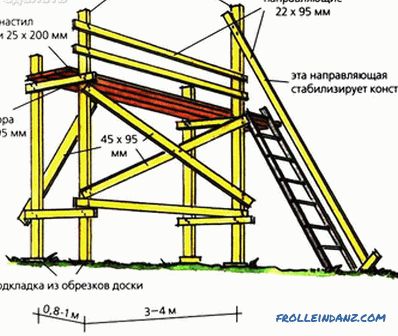

All forests consist of of the following elements:

- racks;

- the spacers are diagonal and horizontal (they give spatial strength to the structure);

- jumpers for flooring;

- flooring from boards on which people will stand;

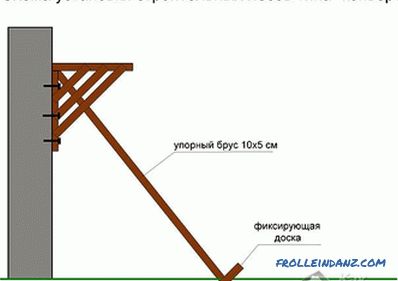

- stops (to create sustainability of forests and prevent them falling away from the wall);

- protecting element (so that the person standing on the floor does not fall down );

- stairs (stepladder) to climb to the desired level of forests.

Made of wood and planks

Wooden

Wooden

How to make scaffolding, on the Internet you can find quite a lot. Moreover, the recommended constructions differ mainly from each other only in the thickness of the board and in the size of the forests themselves. So that you are not confused in all this "diversity", try to focus on the following values:

-

Installation of scaffolding distance between racks - 2-2 , 5 meters;

Installation of scaffolding distance between racks - 2-2 , 5 meters; - the width of the floor for work is 1 meter;

- the height of the whole structure is no more than 6 meters.

Getting Started:

- Prepare the necessary materials in advance:

- boards at least 50 mm thick and 100 mm wide ( or round timber, or timber 10x10 cm) - for racks and stops;

- boards for struts and fences with a thickness of 30 mm;

- boards for lintels and flooring with a thickness of 50 mm;

- nails (screws in this case are less reliable).

Photo instruction

We offer you to look at a number of photos on the topic of how to make wooden scaffolding yourself:

Blanks

Blanks

Assembly of the frame

Assembly of the frame

Holes for fasteners

Holes for fasteners

Bolted connection

Bolted connection

Installing the frame

Installing the frame

Fixing the diagonals

Fixing the diagonals

Growth

Growth

Flooring

Flooring

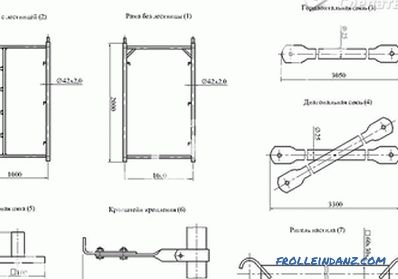

From profile pipe

Metal scaffolding

Metal scaffolding

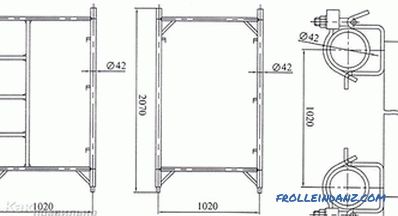

Now how to make scaffolding ( azbornye) of metal (one section dimensions: height - 1.5 meters, width 1 m, length 1.65 m). The number of sections is determined based on the height of the scaffolding you need.

- Prepare the necessary materials:

- for the posts - profiled tube (square section) 30x30 mm - length 1500 mm;

- for struts - pipe with a diameter of 15 mm;

- for connecting inserts (adapters) - 25x25 mm shaped pipe;

- the flooring should be made of boards with a thickness of 40-50 mm and a length of 210-220 cm.

- for diagonal elements - 2 meters each;

- for horizontal elements connecting the posts from the sides of the structure - 96 cm.

“For” and “against”

What should be homemade forests

What should be homemade forests

Firstly, scaffolding is not a small scaffolding-scaffold, but a rather cumbersome structure that will have to be stored somewhere after the need is gone.

Wooden scaffolding, of course, can then be disassembled, but the work is laborious, and even if you don’t need them in the near future, you also need to fold them somewhere. Do not forget that wooden forests are assembled with the help of nails, and not screws, therefore the boards will no longer be completely intact. In addition, when working on scaffolding wood is often dirty with mortar or paint.

Homemade metal scaffolding can be not only disassembled, but later rented.

Secondly, non-factory-made scaffoldings are designed to work at a maximum level of the second floor (from the ground). At higher altitude, the exploitation of home-made forests becomes dangerous.

Thirdly, scaffolding is rarely required (only to repair the facade of a building), so the assembly and disassembly of such a temporary structure is not beneficial in terms of time spent on this work.

Fourth, construction scaffoldings often have to be made long (for example, at least 6 meters for siding installation). Accordingly, their weight increases, and rearranging the self-made wooden scaffolding on the other side of the house becomes a problem even for three or four people.

How to do without scaffolding

Forests should be thought of even at the design stage of a house.

If you do not plan to carry out the facade work yourself (but are going to hire a construction team), then you should not particularly think about the scaffolding, as builders usually come to the site with their scaffolding and scaffolding.

However, after construction is completed (and after some time has passed), scaffolding may be necessary for carrying out small facade repairs. Can this be avoided?

Of course. And first, make sure that the facade of your house does not require repairs for many years. For this, it is enough to use facing bricks when erecting walls. Now it is produced by many manufacturers and at the same time in a sufficiently large color range.

But other facing materials (such as siding, plaster, etc.) will periodically require your attention and, accordingly, additional costs, since you can’t make scaffolding (buy or rent) for free.

Video

From this video you will learn how to make scaffolding for an apartment renovation:

Photo

The photographs show various construction scaffolding:

Hamut scaffolding

Hamut scaffolding

Klino -crumpy scaffolding

Klino -crumpy scaffolding

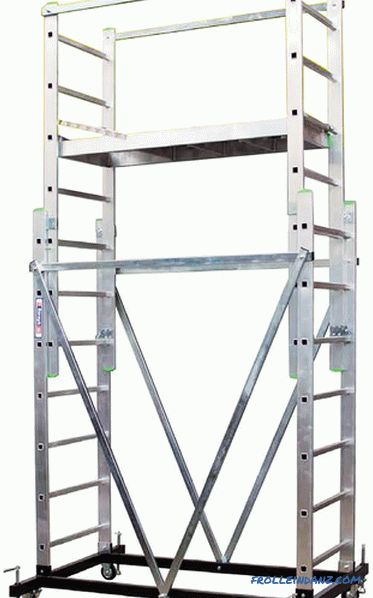

Scaffold tower

Scaffold tower

Metal

Metal

Mobile scaffolding

Mobile scaffolding

For finishing the facade

For finishing the facade

For painting

For painting

Scaffoldings for reconstruction

Scaffoldings for reconstruction

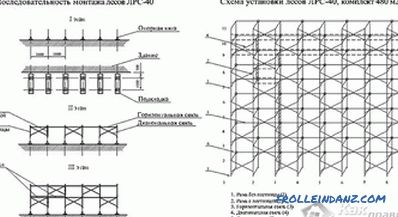

Schemes

Schemes will help you design your own scaffolding:

Basic elements of the forests

Basic elements of the forests

Wooden scaffolding

Wooden scaffolding

Wedge forest

Wedge forest

Scheme of cross forests

Scheme of cross forests

Forest diagram envelope

Forest diagram envelope

Frame scaffolding

Frame scaffolding

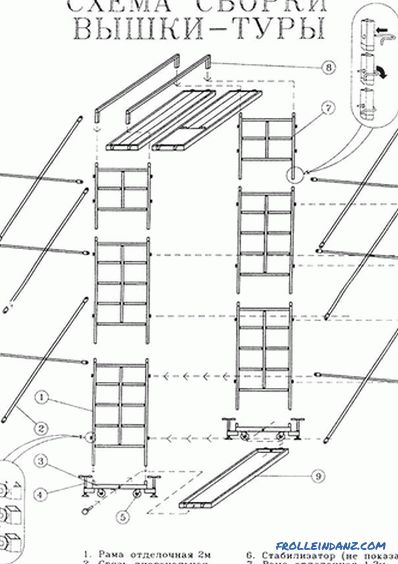

Assembly scheme of the tower tours

Assembly scheme of the tower tours

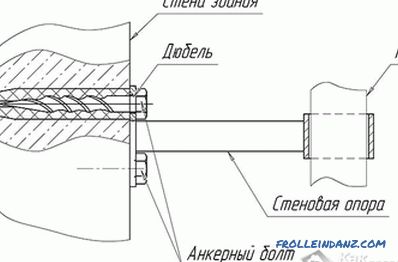

Scaffolding mount node

Scaffolding mount node