It has long passed the time when handicraft furniture was considered the lot of very poor people. In each apartment or house were cabinets, walls, shelves and other furniture, made on the same model. What kind of design could you talk about with such an approach?

Today, choosing the right furniture is easier, but it does not always correspond to the owner’s wishes or hostess preferences. In addition, it often happens that exactly what you need and cannot find, for example, a suitable hinged shelf. In this case, there are 2 options: to order its production in the workshop, hoping that you understand, and the product will be of good quality or you can make the shelves on the wall with your own hands, which will be a good and convenient addition to the designed design.

Types of wall shelves

Types of wall shelves

Types of wall shelves

Thanks to a modern, versatile home tool a craftsman can make almost any regiment, even in the conditions of an apartment, let alone work in his workshop. However, before embarking on a tool, it is important to determine the type of shelf being constructed. This will help the table, which describes the design features of wall shelves and their scope.

| Wall shelf type | Description |

| Classic | It is considered that the classics are part of an ancient culture that has come down to us. It is also called the generally accepted pattern of style. Classic-style shelves are simple to manufacture and have a simple form, so they are easy to make at home. |

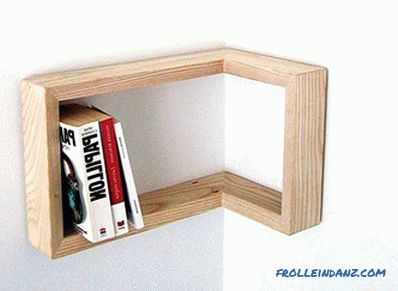

| Corner | Corner shelves have a triangular shape and are attached directly to two walls. Most often this is a small design, placed in the bathroom or in a room where other types of shelves will interfere. Also, the corner shelves can be external. |

| Suspended | Suspended shelves are intended only for hanging on a flat surface and are most often above average. This arrangement allows you to not occupy the free space of the room. |

| Floor | Floor shelves can not only stand on legs, but also, for greater stability, be attached to wall, especially when they are narrow and high. Most often these are shelves of the type of shelves or vertically arranged modes. |

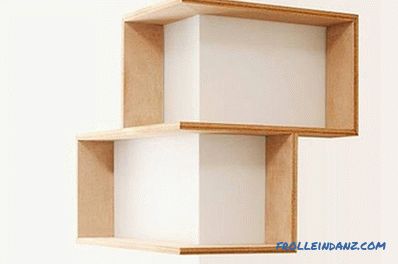

| Modes | The word modus is often used to designate a variety of forms. For this reason, shelves with different sizes of used parts began to be called modi. Sometimes it may resemble abstractionism. Different types of modi can be found in a particular style of the room. |

| Exclusive | This is not a separate section, but a collection of all non-ordinary and non-standard. You can meet the shelves of old suitcases, outlived their TV and even water pipes. There is no limit to imagination. |

Wooden shelves on the wall

Wood is an excellent material, since the shelf made of it will be attractive, solid, ergonomic and practical. Although the rapid development of scientific and technological progress, as well as the appearance on the market of new technologies and innovative materials did not make the use of natural wood less popular and in demand, it is still in demand among admirers of natural beauty and style.

This beautiful figured shelf is made of solid pine

This beautiful figured shelf is made of solid pine

The advantages of furniture from natural solid wood abound, and it is not only an attractive appearance, but also high performance, thanks to which wood has been used for centuries for construction purposes as well as for the manufacture of original interior items. Even without a lot of experience in carpentry, you can make a beautiful wooden shelf. If you are a beginner, then it is best to start with this universal building material, based on soft, low-cost wood for furniture manufacturing.

Manufacturing

First of all, you need to think over the dimensions of the manufactured shelf and decide on the place where it will be, only after that acquire the boards. If the design will be assembled from the material at hand, you will have to adjust to its dimensions.

Of course, one cannot do without a tool. The minimum is a hacksaw and a Phillips screwdriver. Of course, with such a set of tools there is nothing to undertake to manufacture a complex structure.

Video: a minimum set of tools novice joiner

To collect something solid and beautiful, you will need:

| Jigsaw or hand saw | It will be more convenient to work with an electric jigsaw, but if it is not available, you can use a standard hacksaw with a small tooth. With this tool, blanks for the future shelf will be cut. |

| Sanding machine or a set of skins of different grain sizes | You will have to spend a whole manually on what the grinder will do in 5 minutes hour. With this tool, sanding the blanks, and then the entire shelf. |

| Electric drill | If shelves are made of chipboard, then such screws cannot be screwed into screws or reinforced drill a hole under this fastener. In the wooden parts, too, need to drill holes for screws. |

| Screwdriver or screwdrivers | Only if the shelf is small and uncomplicated, can you screw in several screws without pain or screwdriver screwdriver. If the attachment points are many, then manually it will be very difficult to do. It is not recommended to use an electric drill for these purposes, since it will not be possible to control the twisting force. |

| Screws or wood screws. When working with chipboard, it is recommended to fix blanks with confirmers | In addition to the fastener itself, it is advisable to buy plugs to match the color of the shelf. It is important to know that, depending on the chosen fastener, the plugs are selected individually. |

| Varnish for wood | Varnishes for wood are different. Many people prefer to use alkyd varnishes with additives of the urethane group, as it dries quickly (up to 12 hours) and is very durable, which is important for the product, which will often be used. |

| Medium sized brush (40‒80 mm) | The shelf will need to be opened with varnish. At home, this procedure can be performed with a brush. Since most wood lacquers are toxic and produce a strong odor, the work must be performed in a ventilated uninhabited room. |

| Square | With it, you can make all corners even. If this tool is not already there, then you can check the correctness of the corners with ceramic tiles. Accuracy will not be perfect, of course, but still better than nothing. |

| Manual router | You can make a wooden shelf more beautiful with a manual router, with which you can create various decorative patterns on corners, in the ends and in the middle of the product. |

After purchasing wood, you need to inspect it in order to have an idea of how the manufactured shelf will look. The fact is that the raw boards are not very different from each other, but after applying the stain the dark places will be more pronounced than the bright places. If it is impossible to make sidewalls from one board, then pick up boards whose texture will be similar.

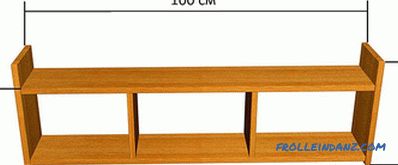

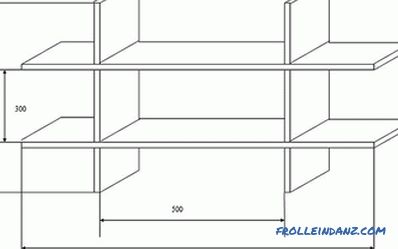

Consider the manufacture of the shelf on an example. Assume that we need a wooden wall shelf for 3 cells, the dimensions of which will be 100 cm in width and 40 cm in height.

For convenience of calculations, the depth of the product will not be calculated. Board thickness - 2 cm. Length of self-tapping screws 40‒50 mm.

Dimensions of the bookshelf

Dimensions of the bookshelf

So, we will need to cut off a workpiece of such a length:

- 50 cm - 2 pcs.

- 96 cm - 2 pcs.

- 26 cm - 2 pcs.

Now we will explain how we obtained such dimensions.

If everything is clear with the sidewalls of 50 cm, then the length of the remaining parts must be calculated. For example, 2 horizontal parts are 96 cm long. Here, too, there is nothing complicated. With a shelf width of 100 cm, we take away the thickness of two boards used as side walls:

100- (2 + 2) = 96 cm.

In a similar way, we obtain the height of the jumpers (vertical 2 parts), with a height of the inner part of the shelf is 30 cm:

30- (2 + 2) = 26 cm.

By itself Obviously, all paired parts (in our case) must be the same size.

Assembling a wooden wall shelf

Each part needs to be machined with a sander, only then it can be bonded with other parts into a single structure. Hands should be kept clean, because untreated wood is very marking.

Back to our scheme, where you can see that the bottom board is slightly elevated above the bottom level, which has 2 explanations: first, it makes the shelf more beautiful, and second, it protects the bottom edge of the side cracks when screwing screws. Usually this indent is within 1 cm, but more can be done if needed. To secure in the place of screwing the screw into the lower part of the sidewall, you need to pre-drill a hole with a thin drill.In our case, they will be at a height of 2 cm from the lower edge of the sidewalls (1 cm indent + 1 cm to the middle of the thickness of the board to be bolted).

Now step by step on the build process.

- Raising the lower shelf 1 cm, side parts are screwed onto it alternately. It is necessary to ensure that when screwing screws, they were located straight.

- Turning the blank upside down, mark the position of the future shelves. If the cell sizes are the same, then we divide 96 cm by 3 (in our example, 3 cells). It will turn out 32 cm. We recede from sides on 32 cm and we put on a board of a point into which self-tapping screws (centimeter 3 from edge of a board) will be twisted. It is better not to draw the line, as it will be visible under a layer of varnish, and put small marks on the ends of the board.

- In this position, jumpers are screwed to the bottom of the shelf.

- The shelf turns over and after checking the vertical position of the jumpers, they are screwed.

- Now it is the turn of fastening the sidewalls to the upper crossbar.

- In order for the shelf to be flat and subsequently not twisted, in the lower part, on the reverse side, it is possible to fix the location of the parts with flat window corners. If the back wall is attached, the corners are not needed.

Flat window corner

Flat window corner

- The assembled design is painted with a stain, after drying which , you can proceed to varnishing.

- The entire surface of the shelf must be cleaned from dust of dirt. After applying the first layer, you need to check if there is any villi in it. If there is, then you need to once again all oshkurit abrasive sandpaper to remove them. If the varnish is thick and does not lay down evenly, then it can be slightly diluted with a solvent recommended by the manufacturer.

- In total, it is necessary to apply 3 coats of lacquer, with a periodicity from 12 to 48 hours. This interval depends on the type of varnish used and the ambient temperature. In any case, you need to wait for it to dry. Check the surface each time for bumps and sand grains. If you notice something, immediately grind with an abrasive sponge until you remove the defect. Then again you need to apply varnish.

- After the varnish has dried, it remains to fasten the hinges at the back, after which the shelf can be hung on the wall.

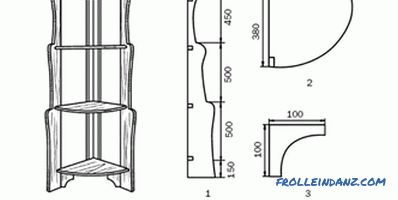

Making an angular wooden shelf

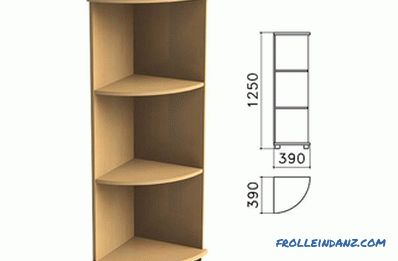

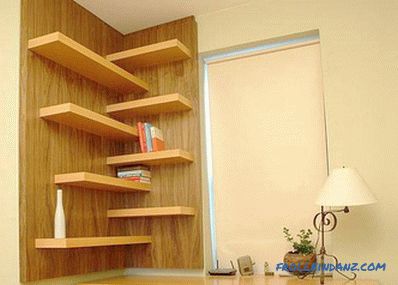

The corner shelves can be of the most varying heights, and have a different number of levels.

Video: Making an angular shelf

Consider the sequence of manufacturing a wooden corner shelf of slats 20 * 50 mm.

We will make such an angular shelf

We will make such an angular shelf

- After examining the slats, you need to select the smoothest, the minimum number of knots - 2 frames will be made of them, 40 * 70 cm in size. For making them, you will need:

- 4 parts of 70 cm length;

- 6 parts of 30 see

- It is preferable to glue frame parts by clamping with clamps.

- Now it is the turn of manufacture of shelves. They can be made:

- type-setting, gluing together several rails, from which details of the desired shape are then cut and edged with a figured lath outside;

- from plywood sheet;

- from laminated chipboard. In this case, the cut must be sanded and glued with furniture edge or something else, at its discretion;

- from a piece of old furniture, if the front part is flat.

- Shelves are screwed to the frames and lacquered.

- It remains to fasten the hinges and hang the manufactured shelf in place.

Hinge kit for a corner shelf

Hinge kit for a corner shelf

For a corner shelf, a set of 2 is best suited loops, as in the illustration. If you hang the shelf on a loop with a wide ear, then the shelf can be moved along the wall, and you can put on the second loop.

Photos of wooden shelves

A shelf for flowers made of wood, covered with copper foil

A shelf for flowers made of wood, covered with copper foil

Corner shelf with base of laths

Corner shelf with base of laths

Corner outer shelf

Corner outer shelf

Corner Bookshelf

Corner Bookshelf

A simple corner kitchen shelf made of wood

A simple corner kitchen shelf made of wood

Carved corner shelf

Carved corner shelf

Schemes

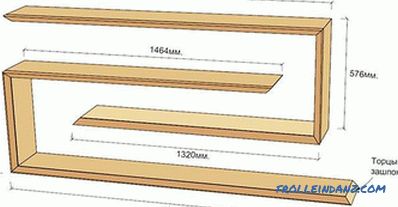

Scheme of a wall-shelf with dimensions

Scheme of a wall-shelf with dimensions

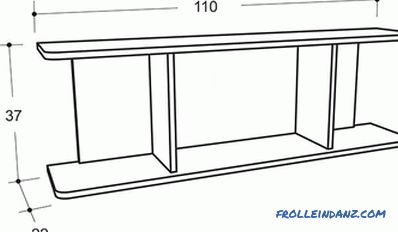

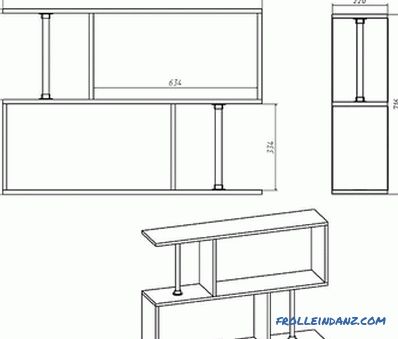

Such a shelf can stand on the floor or be mounted to the wall

Such a shelf can stand on the floor or be mounted to the wall

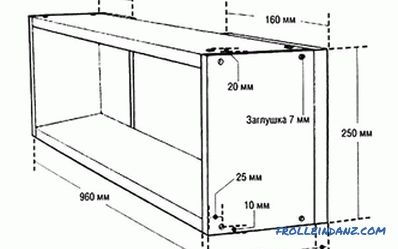

Kitchen shelf shelves

Kitchen shelf shelves

Scheme of the shelf

Scheme of the shelf

Regiment and with protruding parts

Regiment and with protruding parts

Dimensions of the wall shelf

Dimensions of the wall shelf

Figured shelf

Figured shelf

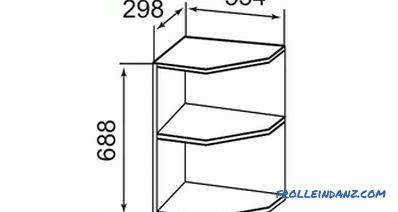

Drawing of the corner shelf

Drawing of the corner shelf

Shelf drawing p-9

Shelf drawing p-9

Shelf for books with your own hands

Despite the fact that electronic devices crowd out printed editions from human life, many people carefully keep books and magazines that are dear to their hearts, the storage space of which often leaves much to be desired. If you have such a situation, it will be useful to learn how to make bookshelves that would be functional and fit into the interior.

Shelf for books

Shelf for books

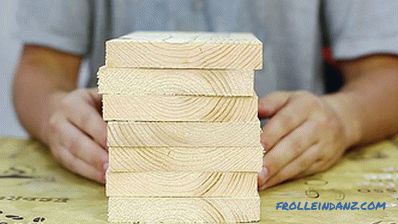

If you are not a specialist, then you shouldn’t immediately start making difficult designs. Next, we look at the process of making a simple bookshelf from the slats.

Work steps

You will need a tool to work:

- electric screwdriver;

- electric drill;

- electric jigsaw or hacksaw;

- tape measure;

- construction square.

As for consumables, you will need:

- slats 20 * 40 cm;

- self-tapping screws on a tree 3.5 * 45 mm (from calculating 2 pcs. per attachment point).

Now you can start making the shelf. The first thing you need to make "ladders" - the side parts (and with a large shelf length and middle too).

The dimensions of the shelf will depend on how large the books are on it. If the books are not large, then the shelves 20 cm wide will be enough to accommodate them. The height of the cells is selected so that it is convenient to take the book from the shelf. Also, the height of the cells at different levels may vary. As for the height of the shelf, this is a matter of personal preference, but it is important to note that although this shelf will be attached to the wall, it is not intended to be suspended, so it will stand on a solid surface.

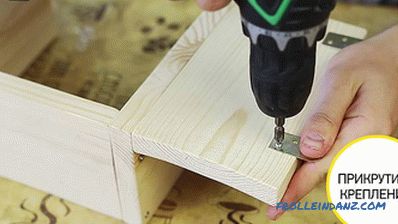

First, the slats are prepared, which will be used as racks, and crossbars are already attached to them, for which holes are drilled at the edges of each plate with a thin drill.

Preparing for the production of the bookshelf

Preparing for the production of the bookshelf

Having fastened the cross member with a single screw, you need to check its position.

Twist the first screw and check the angle

Twist the first screw and check the angle

Align the rail with the second screw.

Having checked the correctness of the angle, we twist the second screw

Having checked the correctness of the angle, we twist the second screw

The assembled "ladders" are laid on the floor, and after checks of the correct angle begin to be fastened with slats, which are cut off, according to the length of the structure.

We assemble the structure

We assemble the structure

Then the rest of the slats are attached.

The frame is assembled. Now you can put to the wall and fasten

The frame is assembled. Now you can put to the wall and fasten

The structure is raised and fixed to the wall, after which the remaining slats used as shelves are fixed.

After fastening to the wall, we install rails for the shelves

After fastening to the wall, we install rails for the shelves

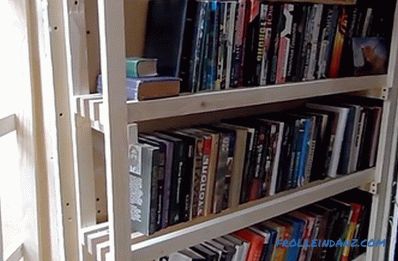

Such a shelf will stand many books.

The reek bookshelf is ready and loaded with books

The reek bookshelf is ready and loaded with books

The assembled shelf is designed for a large number of books, but If you need a less dimensional design, then you should pay attention to the video instructions and photos of your favorite products.

Video: bookshelf on the wall

Flower shelves

You can often see when people decorate their homes with artificial flowers, but nothing is can replace the freshness of a natural beautiful plant. Many owners, trying to decorate the wall, let climbers climb over it, hang vases to the ceiling or place them on the shelves of their own design. The advantage of this approach is that it is possible to make something of their own, unique and fit into the interior of the room. Depending on the type of colors available and their quantity, a shelf is constructed.

Wooden shelf for flowers in the form of honeycombs

Wooden shelf for flowers in the form of honeycombs

Of course, I immediately want to do something volumetric and beautiful, which is quite natural, but first you can try your hand by making a simple but neat shelf.

Manufacturing steps

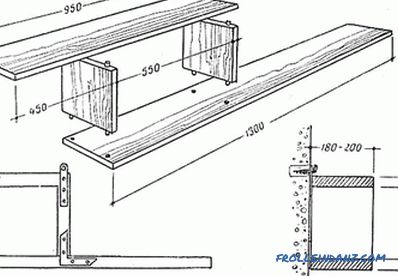

We need a board 120 * 25 mm with a length of at least 130 cm. It will be more convenient to sand the board while it is whole.

Get a board of a suitable size

Get a board of a suitable size

After that, one edge needs to be cut so that the angle is right, and mark every 20 cm clearly at an angle of 90 °. This will help the construction area, but if it is not, then you can use any solid object, the corners of which are straight, for example, ceramic tiles.

Making marks on the board every 20 cm

Making marks on the board every 20 cm

When cutting a part, you need to hold the hacksaw at an angle relative to her If you keep the hacksaw straight, it will be hard to make the cut even.

Now we saw it using our marks

Now we saw it using our marks

For the manufacture of the shelf we need 6 parts of 20 cm each.

We need 6 identical plates

We need 6 identical plates

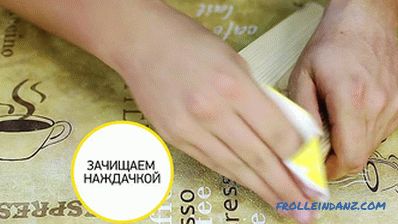

Each part needs to be cleaned with sandpaper on all sides. Used canvas should not be coarse-grained, otherwise you can scratch the wood.

Each of them should be treated with emery cloth

Each of them should be treated with emery cloth

Since the screws will be twisted close to the edge of the board, so that it does not split, in these places you need to drill holes with a thin drill.

In preparation for the assembly, we drill holes for the self-tapping screws

In preparation for the assembly, we drill holes for the self-tapping screws

The entire assembly process consists in fastening the parts with self-tapping screws. If PVA glue is available, the joints need to be spread on them, and, after giving a minute to set the glue, fasten the parts. When screwing the screws do not need to exert excessive effort so as not to split the board. It is enough that the screw head is flush with the board.

We assemble the shelf

We assemble the shelf

As our wall shelf, we need to fasten fastenings to it.

We fasten the fasteners

We fasten the fasteners

Since the height of the shelves is small and the design is not very strong, then You can put climbing or low plants in small pots.

The shelf is ready and there are flowers on it

The shelf is ready and there are flowers on it

Such a product can be used not only for flowers. To the shelf is not dirty, it is best to open it with varnish.

Video: unusual shelves for colors

Original shelves

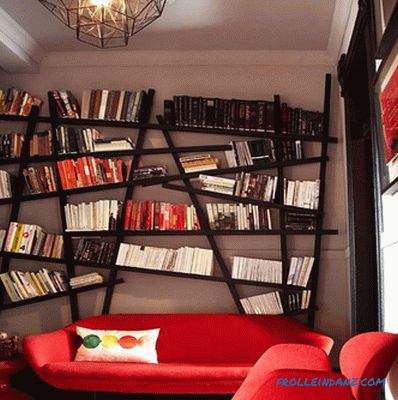

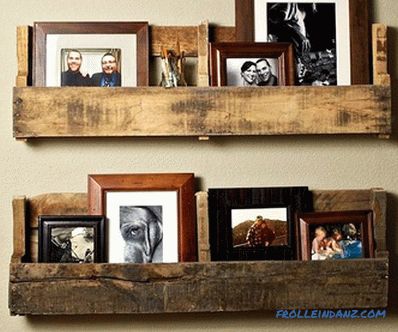

If you want to diversify your interior, you can make convenient, original and beautiful shelves from different materials, hanging them in the office or in the living room. They will help to conveniently arrange a lot of things and can give the rooms a more comfortable look. You can make unusual wall shelves out of wood, glass, plywood, fiberboard, pieces of tin, and even water pipes.

It can be said with confidence that unusual shelves are the epitome of originality and exclusivity. However, in all you need to know the measure and understand that when designing any product it is often necessary to maintain the style of the existing style. But now it has become fashionable to divide the room into zones. After looking at the photo, which embodies interesting ideas, you will take something as a basis, adding your own flavor.

Photos of original shelves

Modern wall shelves

Modern wall shelves

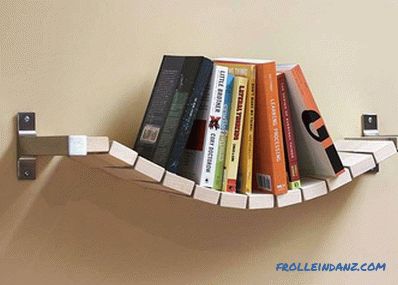

Slack shelf

Slack shelf

Semicircular shelf

Semicircular shelf

Shelf for a flower on a leg from branches

Shelf for a flower on a leg from branches

A shelf in the form of honeycombs

A shelf in the form of honeycombs

Shelf modus

Shelf modus

A shelf of metal rods and wood

A shelf of metal rods and wood

Unusual product design

Unusual product design

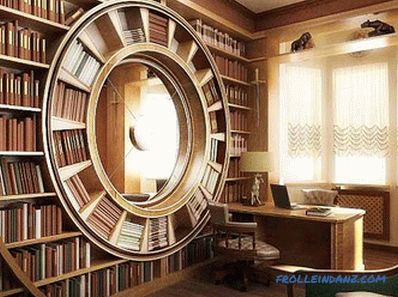

Unusual bookshelf

Unusual bookshelf

Metallic a shelf in the form of a fire escape

Metallic a shelf in the form of a fire escape

Design from an old box

Design from an old box

TV shelf op

It often happens that in a small room, well, there is simply no place to put a TV. For example, a small kitchen and so crammed with furniture, it would seem, what kind of TV can we talk about. However, a regiment located in a corner or on a free wall can become a way out.

In the modern concept, when TVs were simply hung on the wall, the shelf under the TV is called a shelf, located under the TV, on which a DVD player can stand. In either case, the shelf can be made at home. We will not dwell on simple shelves that can be placed under the TV, since we have already touched upon making similar ones to them in the article, but consider only making one on which to put a TV.

Let's start with the simplest - an angled shelf of plywood attached to a wall.In our case, it will be installed near the window, and so that the curtain does not interfere, on the left side we will make a small notch for it. You need to sand the corners of the blank, then glue it all over (or only the upper part) with a self-adhesive tape with a pattern chosen by you.

The corner shelf cut out of plywood must be glued with a self-adhesive film

The corner shelf cut out of plywood must be glued with a self-adhesive film

You must fasten the blank to the workpiece, which it will fasten to the wall. It is necessary to pick up screws, the length of which will be slightly less than the thickness of the sheet of plywood, from which the workpiece has been cut. In our case, the front fastening elements are located below, and the rear ones are from above, but if nothing interferes from below, they can also be installed under the shelf.

Fasteners are fastened to the shelf

Fasteners are fastened to the shelf

Now the shelf has to be set to the required height and the mounting points are marked on the wall . The shelf is retracted to the side and holes are drilled in marked places.

Under the shelf, holes are drilled in the wall

Under the shelf, holes are drilled in the wall

We insert dowels into the holes so that they do not stick out from the wall.

We insert plastic dowels

We insert plastic dowels

Now you can attach the shelf.

The shelf must be firmly fixed

The shelf must be firmly fixed

The shelf must be installed exactly and the fasteners must be well clamped.

This is how the fastener

This is how the fastener

looks like. Now you can install the TV and bring the wires down through the gap left in the corner .

The TV is installed on the shelf

The TV is installed on the shelf

This shelf does not need additional finishing and is immediately ready for use by purpose.

In this article we made a general overview of wall shelves and gave an example of making simple structures. If you want to see new ideas or need help, leave a comment at the end of the article.