Today, any construction store is replete with a huge assortment of building material that can be used in the construction of water supply and heating systems, as well as their periodic replacement. However, products made from polyvinyl chloride are the most common raw material, due to their resistance to aggressive substances. To properly install the PVC pipes with your own hands, you need to take into account the properties of the material and a number of important features when connecting elements.

Main characteristics

The main advantages of PVC are:

- resistance to chemicals and environmental factors;

- ideally smooth surfaces of products exclude the formation of growths, blockages and other deposits;

- a wide choice of component elements allows you to build any pipeline design;

- resistance to corrosion and premature destruction;

- huge period of operation;

- ease of installation;

- low heat conductivity;

- low specific weight and flammability coefficient;

- sealed pipe unification provides for use on floating soils.

Sewage pipe laying

Sewage pipe laying

Disadvantages:

- temperature limitations;

- availability of special fittings.

Assembling communications from PVC

In general, the installation of plastic pipes is a combination of individual PVC elements, fittings and accessories into a single tight network . It is carried out by means of three technologies:

- by the socket method;

- by the method of "cold welding";

- by the use of special couplings.

Installation using the first method in most cases is used in the construction of sewer systems, since it is the simplest and provides for the usual fixing of the end of the connecting pipe in a rubber gasket.

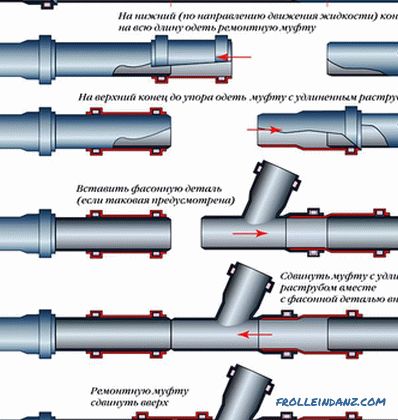

The second method is to use a special chemical composition that ensures reliable contact of all the elements. The third method is operated by connecting pipes of different nature, for example, from metal and polymers.

Preparation

Fittings

Fittings

Preparatory work is an extremely important procedure that provides a clear organization of action and the availability of all necessary tools. The first step is to create an approximate scheme that fully reflects the number of fittings, pipe sizes and their number. Before cutting PVC pipes for adhesive bonding, preliminary measurements should be carried out on a dry surface. The ends of the connecting elements must be cleaned and degreased. Cutting is carried out by means of an ordinary hacksaw or a special cutter. Do not forget that the fixation of pipes is ensured with the help of special brackets attached to the wall.

In order for the cut to turn out to be even and tight it is worthwhile to preliminarily outline the pipe in the place of the future cut. Cutting is carried out strictly at an angle of 90 °. The remaining irregularities are cleaned with a knife and sanding paper.

The connecting pipe should enter the fitting device by no less than 2/3. Then the cut points should be cleaned with a cleaner, which not only removes all the dirt from the edges, but also softens the future fixing point somewhat. The inner space of the fitting and the end of the pipe are covered with a small layer of glue, then tightly clamped for 1 minute. At the junction of the elements should form a uniform adhesive ring, which should be cleaned with a dry cloth.

Installation of sewage

Having finished with all the preparatory measures, it is necessary to make the installation of a future construction. During the construction of sewage all the work is carried out from the risers to the plumbing fixtures. The connection of sewer pipes with fittings is carried out by simply fixing a piece of product in a rubber gasket of a fastening device. The main thing - to insert the pipe without bevel until it stops. Loose contact may subsequently lead to an unpleasant odor.

It will be useful to check the place of the future joint and the rubber layer for dirt and dust before performing this procedure. To ensure a more reliable connection, it is necessary to lubricate the end of the segment to be joined and the gum of the fitting with soapy water or glycerin grease.

Sewerage

Sewerage

After the main communication is ready, you should start connecting all plumbing fixtures, do not forget to equip the sink and bathroom siphons. The next major step is to test the system for tightness. In this situation, it is necessary to turn on all the plumbing in the house and check all connections for leaks.In addition, you should see how the structure will behave in critical situations - type a bucket of water and drastically pour it into the sink or washbasin. If there is no moisture on the floor, it means that the work was carried out efficiently and effectively, but if there are leaks, then the “problem” areas should be dismantled and re-fixed using different adhesive compositions. Next, repeat the test.

Installation of water supply

Any water supply system is subject to high pressure, therefore, a special welding machine (ironing) will be required for the installation of water supply pipes. Having finished with all the preparatory activities, we proceed to the assembly of the entire structure, which, as in the construction of sewage systems, should begin from the riser. Before using welding equipment, be sure to read the attached technical documentation. Depending on the power of the heating element, the heating time of the connecting elements may vary.

After the heater is ready for use, insert the connecting pipe and fitting from different sides into the heated nozzle and wait for about 15-20 seconds. Then carefully remove them from the device and immediately insert them into each other, while observing the required connecting corners. Then in this position it is necessary to fix for 10-15 seconds so that the plastic elements have time to grab. The resulting compound will function for a long time due to the fact that the structure of the two components will become one.

In no case do not neglect the precautionary measures: protective goggles and gloves are supplied with the welding machine. The slightest contact with the heating element can cause severe burns.

Financial benefits from the use of PVC pipes can be traced at almost every stage of independent construction - from planning to launch. The use of this material will allow to avoid calculations of transient coefficients at the stage of arranging a metal pipeline. During operation, such communications are unpretentious, since they do not require preventive maintenance and additional staining. However, the material is environmentally safe, which allows it to be laid in the ground, thereby accelerating the launch of the water supply system.

Video

This video shows the adhesive method for joining PVC pipes: