The rules for wood processing have existed since the beginning of the construction of houses from wooden log cabins. The tree was protected from rotting, dampness, beetles, burning by various means: plastering with clay, coating with varnishes, impregnations and paints. And even in the simplest ways, up to the selection of the driest place for construction, a solid roof that protects against leakage, by raising the frame on the piles. Current processing trends already suggest the water-repellent and protective functions of wood.

Oil treatment protects the wood from: beetles, rodents, mold and rot.

Possible means of wood processing

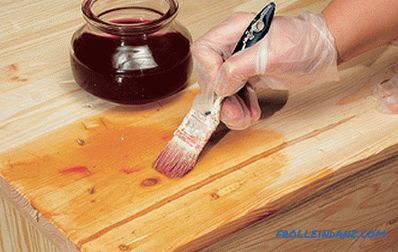

The technology of impregnation of wooden sleepers for railroad tracks offers treatment with creosote, simply tar oil. Besides it, other processing of wood is possible with the help of the following substances:

- wax mixed with a solvent;

- linseed oil, which contains solvent;

- drying oil;

- used engine oil.

Composition for impregnating wood.

There are a lot of controversies about the latter. Especially dangerous is the oil used in industrial areas and heavy equipment. Another option is to use motor oil from cars. Within a few days, it loses its acrid smell and destructive properties. Undoubtedly, this substance, like oil-impregnated machine, can be used exclusively for processing non-residential wooden premises. For example, sheds, warehouses, various wooden buildings, cranes of wells, garret elements and other structures. Experienced carpenters have long been working with oil on hidden elements of buildings such as rafters, ends and overlaps of beams, inside out and logs of floors and partitions of walls going under the cladding.

Treating wood with waste oil is precisely in those places where the possibility of wood contact with the ground is great, where the log house has open surfaces that later will suffer greatly from external temperature and other influences, for example, near the roof or foundation.

Particularities of machining with oil

In the absence of other means of working wood, such as wood varnish or polymer paint, you can apply waste oil where the rest of the protection is powerless and the owners do not pursue aesthetic goals of decorating the facade of the building .

The advantages of using such an impregnation for wood are low cost and reliability.

Oil treatment for wood protection from bugs, rodents, mold and rot for a long time, will retain the wood hardness and color.

Even a partially affected area of a wooden frame can be safely covered with oil.

For optimal exposure, it is recommended to prepare a mixture of tar and oil. Melting the tar paste in a metal container and pour in the waste oil composition into the mass that has not cooled to the end. The proportion of the mixture should be 1: 1. If the oil is already added to the cold melted tar, it is better to pour less of it. But to apply such a mixture on a wooden surface is best in a warm form. After application, the oil itself is absorbed and dries without additional help.

As for the flammable properties of the waste oil fluid, this is also a controversial issue. The fact is that the composition of the oil for the engine of the car initially add special substances that prevent burning at high temperatures. Impregnated waste oil tree will burn worse than untreated. Nevertheless, it will burn, so before you apply it to the surface of the tree, you need to take care of the safety of the wooden structure.

It is forbidden to use transformer and transmission oils for wood impregnation. If necessary, give preference to waste oil fluids of mineral properties.

Didn't find the answer in the article? More information on the topic:

-

Processing of wooden floors

Processing of wooden floors: how to save the flooring. Varnish, wax, oil, advantages and disadvantages of materials. All the secrets of wood flooring tools.

-

How to make a cauldron of a wooden house?

Cauldron of a wooden house: features of the choice of material for carrying caulks, technology caulk of a wooden house. Tools and materials used in the work.

-

How to impregnate wood with

Oil impregnation of wood: what is required for it. How to choose the right oil and how to apply it. The difference between softwood and the importance of additional surface treatment.