The so-called foam concrete blocks, well known even to non-professionals, have long been successfully used in modern construction. Building materials of this class noticeably surpass similar materials in a number of parameters and are characterized by the following indicators:

- relatively low weight,

- low thermal conductivity,

- convenience and simplicity processing.

We note right away that it is possible to realize all of the above advantages only after becoming familiar with how to plaster walls from a foam block. Thus, well-organized wall decoration is the main condition for improving the durability and strength of the outer coating.

Advantages of plaster

Plaster for foam concrete

Plaster for foam concrete

Plastering surfaces from foam blocks allows you to All the above advantages of this material provide the following advantages to the prepared coating:

- It increases its thermal insulation characteristics.

- Protects the structure from dampness and dirt, which can lead to its destruction over time.

- Reduces the influence of the main climatic factors determining the deadlines for the operation of the structure.

- Creates normal conditions for effective outflow of moisture from intra-wall spaces (increases their vapor permeability).

Preparing for plastering

Primer of foam concrete

Primer of foam concrete

Immediately before plastering walls of foam concrete blocks, the entire surface of the latter is necessarily primed. For these purposes, so-called deep penetration mixtures are used, which act as a base for plaster and are applied to the treated surface in two layers.

To improve the quality of plastering the exterior walls of a building, it is recommended to use primers, which include hydrophobic substances. In addition, the top layer of plaster is recommended to treat a special water-repellent impregnation. Such an operation helps to prevent the spread of cracks along the outer layer of the coating, which can also lead to cracking of the plaster located under it.

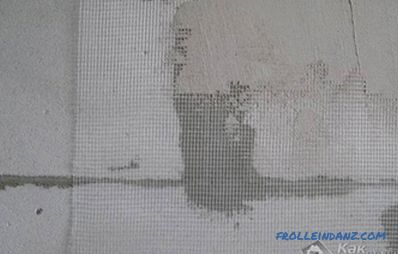

In addition, to enhance the adhesion of the surface of the foam concrete with the coating, a special reinforcing (fiberglass) mesh, which is characterized by increased resistance to aggressive alkaline media, is attached to it immediately before plastering. Such reinforcement of the structure significantly increases the strength of the surfaces being formed and is usually used only on problem areas (in the joints of adjacent surfaces, in window and door openings, etc.).

Constructions of foam concrete blocks do not need a thick layer of plaster; in this case, the thickness of the finish can be no more than 2–3 centimeters.

Requirements for the quality of plastering

Requirements for the plastering of foam concrete

Requirements for the plastering of foam concrete

The main condition for obtaining high-quality protective coating is the use of plaster mixture that meets the following requirements:

- Durability and durability.

- High adhesion with foam concrete.

- Resistance to sudden temperature fluctuations.

- Good water repellency.

- Good vapor permeability.

Special plaster mixtures designed for the decoration of walls from foam concrete blocks fully satisfy these requirements.

Packages with foam concrete mixtures are usually marked with a special marking, indicating that the solution prepared on the basis of them can be used for finishing surfaces with a cellular structure. As for the price, these mixtures are somewhat more expensive than classical finishing compositions. But in this particular situation, you will have to come to terms with the costs, since it is only with the help of these mixtures that it is possible to obtain high-quality coverage.

The distinctive features of plaster for porous substrates are clearly presented in the following video:

Plastering walls from foam blocks

Fiberglass mesh

Fiberglass mesh

As for how to plaster the walls of the foam block, the sequence of operations, which should be followed in this case, may look like this:

- First of all, the surface to be plastered is treated with a primer that is suitable for cellular structures.

- Immediately before plastering, a fiberglass mesh is mounted on the surface of the walls, which makes it possible to reinforce the finishing layer (increase its contact with the surface of the base).

- Following this, you can proceed to the finishing of the facades with plaster mixture prepared on the basis of your chosen dry composition.

- A small amount of plaster, prepared in the right proportion, is applied with a spatula to the primed surface and carefully leveled.

After the mortar “grasps,” you can evenly distribute it over the entire surface to be finished using lightweight smoothing motions.

We recommend reading:

- leveling the walls with drywall with your own hands;

- how to properly glue the ceiling plinth.