The blockhouse is a modern building material used in the exterior of the building. It is in demand from the buyer. This is mainly due to the high price of natural wood, which makes the construction of a chopped house something from the realm of fantasy.

When choosing a block house, give preference to pine products.

For those who can and love to equip their home on their own, it will be nice to know that installing a block house with their own hands is a very doable and easy job. It does not require you to build and carpentry. To do a house installation with your own hands, you need a little desire and as much experience in tiling or working with plasterboard. It should not be forgotten that the installation of external and internal, though similar in technology, but each has its own distinctive features.

Selection of materials and tools

Defects allowed in the production of each block-house variety.

The lion's share of the difficulties that may arise in the process of work, you can "purchase" yourself by buying low-quality blockhouse. This will result in not only painful hours of work, but also a short lifetime of the coating. What do you need to know when choosing a blockhouse?

First, it is made from both tree species (larch, pine, linden), and from synthetic materials (vinyl and galvanized metal). The installation of a house block of vinyl material repeats the look and color of wood. But it also has several advantages over the latter. Vinyl fireproof, more durable in operation, not subject to UV light, moisture, deformation. The metal blockhouse, or metal siding, is also a frequently used finishing material.

Secondly, when choosing a blockhouse, carefully inspect the material. The bar is often already packed in polyethylene, it needs to be opened. And check the purchase for the presence of cracks, knots, blue in the face, mold or putrefactive raid. Focus on casting. Not more than 0.8 cm wide and 0.3 cm deep. Notice how the one-year-old rings are. The more densely they are located in relation to each other, the more dense the wood will be.

Assembling a house block with your own hands will seem much easier if the necessary tools are nearby. Assemble it in advance, and then nothing will distract you from the installation process. So, you need:

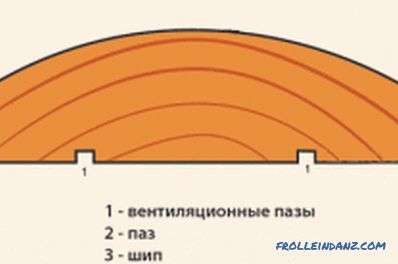

The structure of the block house.

- Power Drill. Without it, nowhere. It will help to make holes for screws.

- Screwdriver. It is necessary to quickly and easily screw the screws, attaching the panel.

- When making the fasteners, take the Klyimer, a simple fastener that connects the panels to each other. It has a screw hole and tongue holding the panel. Its height is not less than 6 mm. Advantages: lack of visualization from the front side, reasonable price. Consumption - 200-250 pieces / 10 m 2 .

- Electric saw or jigsaw. With them you will cut the panels to the required length. The advantage over hand tools is a smoother and cleaner cut.

In order not to redo the work twice, correcting the shortcomings, it is necessary to foresee what else might be needed. We are talking about heat and sound insulation materials. Well in this role look plates of fiberglass or mineral wool. Fire safety and functionality attached.

When making the crate under the blockhouse, use a wooden bar.

To determine its quantity and size, you need to know exactly such parameters as: height and width of the wall, width and thickness of insulation.

Do not forget about another important point - waterproofing. It is necessary to carefully avoid excessive moisture of the walls and insulation material from the resulting condensate. In this capacity, the following materials look good: asphalt, membrane material, vapor barrier plate, perforated film.

Preparatory work: features

Before proceeding directly to the house trimming using a house block, you should acclimatize the panels to the weather at your place of residence. 2-3 days at the place where they will be installed is enough. In the meantime, this process is taking place, you can do some preparatory work, namely:

Blockhouse wiring diagram.

- Fix the vapor barrier on the walls with an overlap method. This will help you sticky aluminum foil / aluminum tape.

- On top of this layer, mount the crate using wooden bars. Pre-treat the timber with antiseptic. This will prolong its life. If the wall is wooden, then simply screw or nail the bars, screws, or nails, respectively. If it is a brick, a frame dowel and a prepared hole for it will come in handy. The distance varies based on the width of the insulation roll (usually 60 cm).

- In the formed openings they put a heater covered with film on top. For greater tightness, the film is placed overlapped and fixed with a construction stapler.

- Following this, an additional layer of the batten is attached directly under the blockhouse. Do not forget to use the level

Independent installation and design

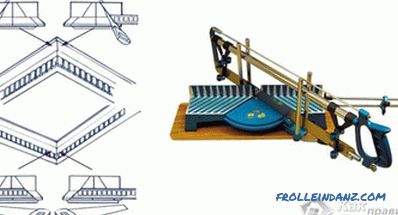

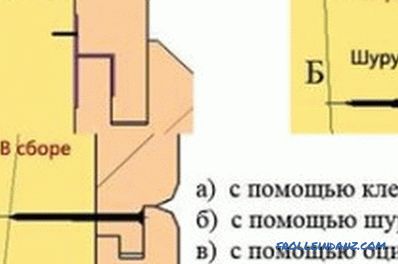

Types of installation of the block house.

It remains the case for the small - to install a block house. The work is not difficult, it consists in fastening the cladding elements using the “thorn into the groove” method. In the construction, besides fasteners, grooves are made. They provide ventilation and relieve pressure, tension from a versatile load. Located on the back of the panel.

The blockhouse elements begin to be fixed from below, unlike the other facing elements, strictly horizontally. The first part is a groove down to the clamps. With this arrangement in the grooves will not accumulate moisture, since the spike is at the top. Then put on the next panel, screwing screws to the crate in the drilled hole. An angle of 45 ° above and below the board. Thus, the panels are stacked to the top of the building. You can decorate the screw heads with special plugs or blockhouse fragments.

The design of corners will be the most time consuming. It can be done in several ways. With the help of ready-made decorative elements consisting of an external wide and internal corner, which are specially sold to stores.

Another option is to make the corners with your own hands (cutting a semi-circular groove for each panel). A good option, but affordable for professionals.

The best option is to mount in the corners of ground bars with grooves identical to those of the blockhouse. If everything is sawed off perfectly, snug fit is ensured. At the window and door openings are placed trim, decorated according to the taste and preferences of the owner.

A few words in conclusion

Do not be afraid to take on the job yourself. This is pretty easy. In this case, a good incentive to work will be savings, because the installation of a blockhouse is an expensive service. And the experience and knowledge gained in the work will be truly invaluable.

Didn't find the answer in the article? More information on the topic: