The stove-stove for heating the premises began to be widely used a hundred years ago. After the central heating appeared, metal stoves moved from apartments and houses to summer cottages and garages.

One of the most significant drawbacks of the stove is its heat transfer conditions. Its heat is not accumulated by anything and almost everything goes out through the pipe. Such a furnace is effective only near the installation site and only during the burning of the fuel.

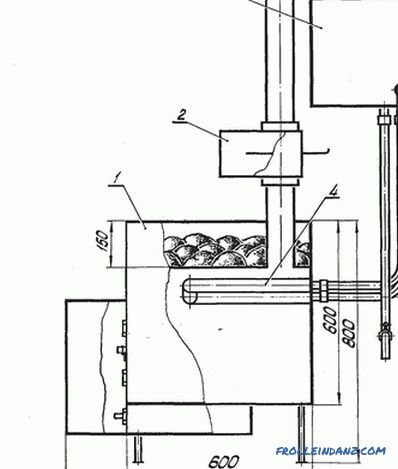

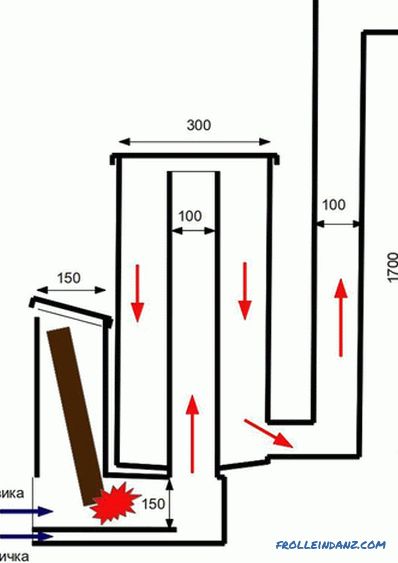

In order to increase the efficiency of the stove, it is necessary to use the lost heat. Maximum losses occur through the chimney, which is heated when the stove is working.

The chimney can be turned into a heating element by changing its direct shape to a stepped one, due to which the heat transfer area increases.

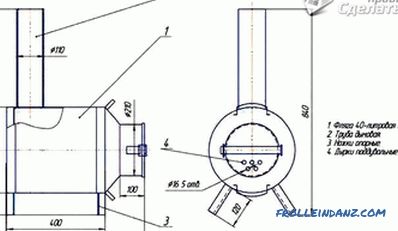

In this article, we will explain how to make a burzhuyka for the garage with your own hands from various materials. The easiest way out is to take the old gas cylinder (in which propane gas was transported) as a basis. In the absence of a cylinder, you can use a 40-liter milk flask or any other metal billet.

From a gas cylinder

It is necessary to begin work from a drawing, not on paper, but on the container itself. Marker marks the future door of the furnace and blew. The door should be located in the center of the cylinder, and the blower - in its lower part. The distance between them is kept no more than 10 cm, and a closed line is drawn in the middle. On it the Bulgarian the cylinder is cut on two parts.

A lattice is welded from 16 mm reinforcement, which is welded to the lower half, after which both parts of the container are joined again.

Cuts are made in places intended for loops. Then hinges are welded there and the door is cut. The same operation is carried out with a blower.

It remains to equip the chimney. To do this, the grinder cuts off the valve, and in its place a metal pipe is welded, the diameter of which should be 80-90 mm. The chimney crashes into the garage exhaust system or goes through the wall to the outside.

From a cylinder

From a cylinder

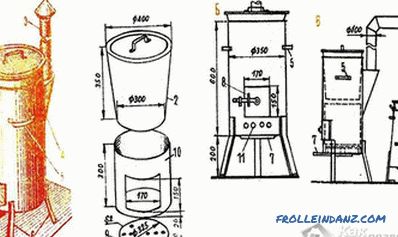

From a milk jar

The scheme of the stove from the flask

The scheme of the stove from the flask

The metal can is a great thing on the farm, suitable for storing paints, engine oils, fuel. The design of the flask is ideal for the manufacture of a wood stove out of it, but as a heating device it will not be as durable as we would like, its walls are not thick enough. With confidence we can say that it will be enough for 2-3 seasons.

As an independent production of the stove, you need to perform several operations.

First you need to mark, and then cut in the bottom of the can, almost at the very bottom, the hole for the chimney. In the final stage of work, the pipe is seized by welding. The diameter of the chimney is selected from 8 to 12 cm. The chimney is extended after the stove has been manufactured and installed.

A can lid is a finished oven door with a good latch, it only remains to drill a few blower holes, the diameter of which can be 15-18 mm. This is done at the bottom of the cover.

Four legs of equal length are made from the corner or scraps of pipes, which are then symmetrically welded to the bottom of the can. A metal sheet can be laid in front of the door, so that a randomly fallen ember does not get on the inflammable material.

Flask handles - a handy thing to carry the stove from place to place, holding them you can easily shake the ash accumulated in the stove. It is for this operation that the chimney is best made detachable.

Well, that's all, it remains only to experience a new stove.

Installation

The use of home made stovets, like any other heating installation, requires strict adherence to safety regulations. Initially, you should choose the place to install the stove. This unit, as practice shows, it is better to install in the corner, namely, near the walls, opposite in location to the garage door.

Do not place the stove closer than 1.5 m to the location of the vehicle. It is worth considering that all flammable materials and products should be located at a distance of at least 1.5 m from the stove.

It is better to overlap the stove with brick walls on all sides. Thus, the probability of touching the hot furnace will be excluded, and the heat generated from its furnace will also be accumulated. Thus, you will increase the efficiency of the device several times.

Increase the efficiency of the stove

Increase the efficiency of the stove

If the walls of the garage are made of wood, then between them and the stove should be a certain distance, namely, not less than 100 cm. In addition, in order to avoid building ignition, the walls near the stove should be lined with asbestos sheets / bricks or other refractory materials.

As a base under the stove, you can use a sheet of steel having a thickness of 1-2 cm. Another option is to fill the concrete screed. Thanks to these actions, you can prevent the spread of fire, if coals / sparks, etc., fall out of the firebox, etc.

To use the stove in the garage, you must first make high-quality ventilation in it. Fresh air should come in here in sufficient volume, which will ensure the normal burning of the fire. A small gap between the ground and the garage door may well serve as ventilation. Otherwise, you will have to make a special channel for timely air flow into the garage, which is not very profitable from an economic point of view.

The stove becomes hot during burning in its firebox, therefore it is impossible to leave flammable materials around it, such as wood, oil and grease, gasoline, etc. This can lead to a catastrophe.

With a burner

With a burner

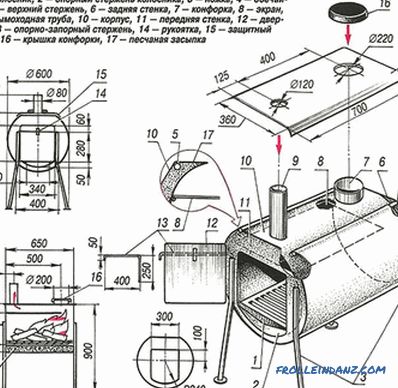

If you equip the stove with a water tank, you can use the stove for its heating. Having installed on it rings, you will have an opportunity to carry out also heating of food.

It will take no more than 2 hours to complete all the work on the manufacture of the stove, and it will be possible to rejoice in the results of your work for several seasons.

Video

A successful example of creating a potbelly stove from improvised means in a video format:

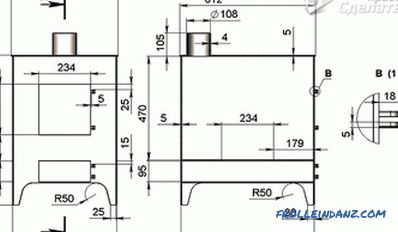

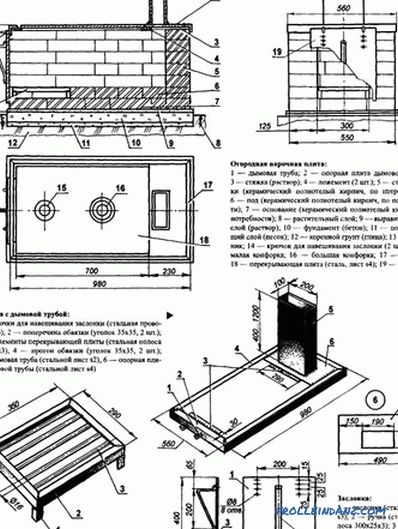

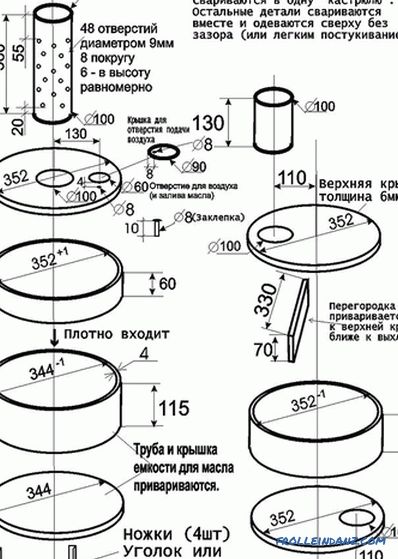

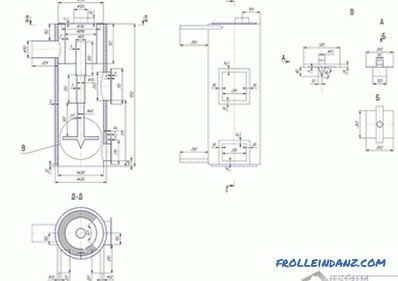

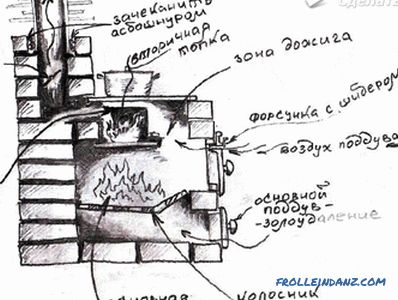

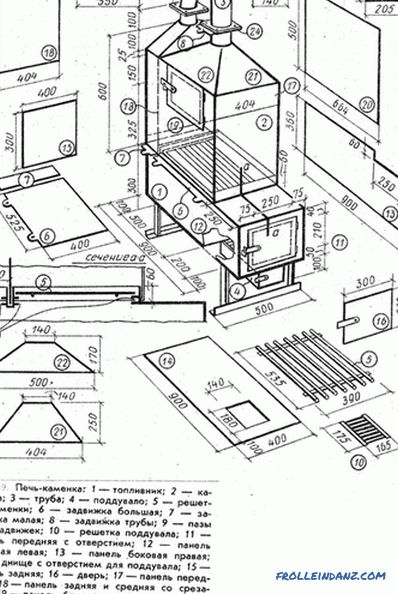

Drawings

Suggested by us Drawings and diagrams will help you understand the principle of making a stove for heating a garage:

Scheme of a rocket stove

Scheme of a rocket stove

Layout diagram of a gas stove from a gas cylinder

Layout diagram of a gas stove from a gas cylinder

Scheme of a double burner

Scheme of a double burner

Pyrolysis

Pyrolysis