Wall-mounted cabinets are integral parts of any modern kitchen. They are used to store dishes, cutlery, food and other utensils. Today there are wall cabinets are quite expensive. Not every person can afford to buy them. Hanging cabinets with their own hands - this is a great solution to this problem. In fact, make them quite simple.

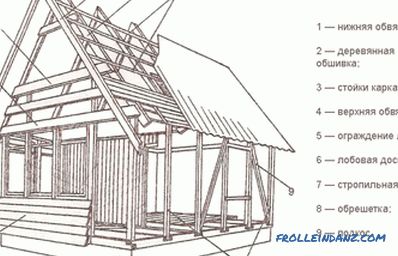

Assembly diagram of the hinged locker.

Wall-mounted cabinets for the kitchen with their own hands and shelves for them are made according to a certain technology, depending on the selected material. There are several possible options. So, then we will talk in detail about how to make wall mounted kitchen cabinets with your own hands.

Recommendations for choosing materials

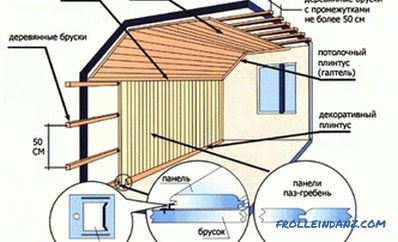

Detailed view of the side wall of the wall cabinet.

The modern market is replete with various materials that people use to make this or that furniture with their own hands. As for wall cabinets, then preference can be given to one of the following types of materials:

- Plywood. Used for the manufacture of wall cabinets for the kitchen with their own hands. It is inexpensive and durable enough. A significant drawback of plywood is the fact that it is poorly processed, and the smooth and even sheets on the market are not so cheap.

- Chipboard. Pretty cheap stuff. It looks ugly, but it can be used for decoration of country buildings, as well as for the manufacture of cabinets in the country. For an apartment, this option is unsuitable.

- Chipboard. This material today is considered the most popular among those used in the manufacture of furniture. To make hinged cabinets with it means to get a reliable piece of furniture, moreover, quite attractive in appearance.

- Plastic. Also popular among ordinary people. This material is great for the kitchen. It is simply cleaned, light enough. Of course, he also has its drawbacks. This stuff is expensive.

Most experts advise using chipboard for self-fabricated wall cabinets. It is on this material and dwell.

Tools required for work: level, hammer, screwdriver, tape measure, screwdriver, hacksaw.

So, the material is selected, now you need to think about what tools you need for later installation. The main ones will be the following:

- level;

- screwdriver;

- hammer;

- screwdriver;

- metal hacksaw;

- tape measure.

This set is quite enough to produce a full range of activities for the assembly of the cabinet with your own hands.

Fittings will be an integral part of wall cabinets. The main thing is to choose it correctly. After all, each cupboard in the kitchen has its own specific function. For example, for a dishwasher it is necessary to purchase additional metal inserts and a plastic pallet.

The cabinet may have glass doors. It will be used to store especially significant and expensive things that are not ashamed to show everyone around you. There are other options that you can do with your own hands.

Direct assembly of the product

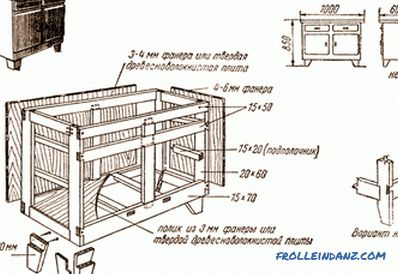

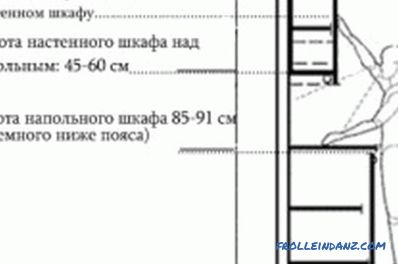

The mounting height of the wall-mounted cabinet.

Now all the tools, materials and fittings are ready - so you can proceed directly to the assembly. By the way, LDSP is better not to cut it yourself. All the work should be entrusted to the employees of the store where the material was purchased. They will do it much better. A person can only assemble a cabinet.

Before you start work, you must release the room from all that may interfere with the work. All tools and materials should be decomposed in such a way that they do not interfere with further work.

First, the side walls of the cabinet are marked. Further, in accordance with the drawing, they are drilled holes of appropriate diameters. On the shelves of the hole are drilled according to the already prepared, which were previously made on the walls. When working, it is important to use a high-quality measuring instrument that will give a minimum error. Laminated chipboard is made of sawdust, so when drilling it is necessary to keep the part as smooth as possible. There is enough one awkward movement, and the drill will come out.

Holes will be needed for removable shelves. They are drilled with a diameter that will correspond to the diameter of the shelf holder used in this particular situation.

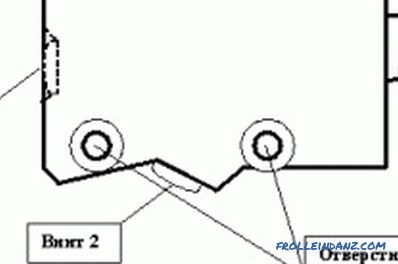

The assembly of the wall cabinets itself is quite simple. It takes relatively little time and effort. First, all the shelves are screwed to one side. Further, on the rear shelf, holes are made for adjustable awnings. Installing DVPO. Now you can easily fasten the second side wall to the overall structure. Now a canopy is attached to each side wall.In this case, it is still too early to tighten the fasteners. Next set loops with facades. They need to attach only previously. So that they do not interfere with further work, they should be removed again. So the cabinet will be much easier to hang on the wall.

Now it only remains to mark a place on the wall for the mounting plate, and then hang the cabinets to the right place. Most importantly, in this case you do not need to hurry anywhere. Only with proper execution of the strap will the cabinets hang really evenly. To level it you need to use a level. In this case, the liquid version will be very useful.

Work execution nuances

Adjustable canopies are able to withstand quite a large load.

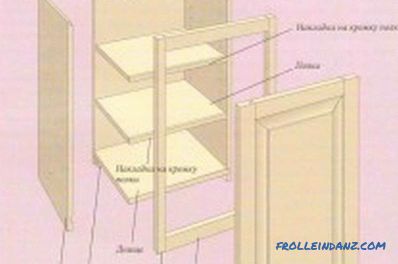

Mounting components for wall cabinets.

It is about 40 kg. In accordance with this parameter, it is imperative to evenly distribute all the utensils and kitchen utensils on the cabinets so that they do not fall off and fall.

No need to spare screws. For a more rigid attachment of all elements, it is better to screw them in as much as possible. However, do not forget about the aesthetic part of the work.

It is worth noting the fact that the width of wall cabinets for the kitchen should not exceed one meter. Otherwise, the bar may simply sag. It will not look very nice. In addition, outwardly such cabinets also do not look very aesthetically pleasing. A large and bulky copy can be installed somewhere in the hallway, but for the kitchen it does not fit. It is important that everything looks harmonious.

The cupboard that will be used for dishes must be equipped with a tray. As it can be any plastic container. Today, such pallets can be purchased at hardware stores. It is very important that it completely covers the bottom of the cabinet. This can get moisture, which in the near future can cause all the material to become unusable.

Work related to the manufacture of wall cabinets for the kitchen with their own hands, and may drag on. This is not to be afraid. In this case, the rush is not what. As the old Russian proverb says, measure it seven times and cut one. This also applies to hinged kitchen cabinets.

Thus, it is possible to summarize some of the work done. As is clear, the whole process of preparing material for work and assembling kitchen wall cabinets with their own hands takes not so much time. At the very beginning, it is imperative that you thoroughly prepare yourself so that then everything goes like clockwork. Otherwise, it is likely that the quality of the assembly and performance will leave much to be desired.

Be sure to need a preliminary drawing and a sketch of the product. Otherwise, the work may also not go according to the planned scenario, and this is unacceptable. Even the smallest nuances must be taken into account. All fittings and fixing tools must clearly correspond to their intended purpose. Buy all the materials better in specialized stores. Here, most products are of high quality. It is not necessary to purchase accessories in the market shops. Chances of buying not quite high-quality products.

Didn't find the answer in the article? More information on the topic:

-

High-quality furniture from shields with your own hands

Furniture from the boards with their own hands. Preparatory work. Full production of a bed from the first to the last step. The time after which you can begin operation.