Sawdust is considered a natural insulation of universal value. They help in the cold period to warm the roof, floor, walls. Despite the appearance of a significant number of modern materials today, this natural raw material does not lose its position. The recommendations below will help to conduct wall insulation with sawdust, according to the established standards.

Sawdust wall insulation technology.

Mostly wood chips are wood waste. Choosing them among a wide variety of materials, you can significantly save money. Moreover, the natural basis is absolutely safe from the point of view of ecology.

Varieties of insulated buildings, used mixtures

Sawdust is used as a warming material in the process of building a bath, one-story buildings, as well as houses with attic. And they can get enough sleep at any time after the construction shrinks.

Before work, wood chips should be thoroughly dried, two months will be enough for this. Excessive moisture in natural raw materials can serve as a fertile ground for the reproduction of fungi and mold, which can very quickly spread to the walls.

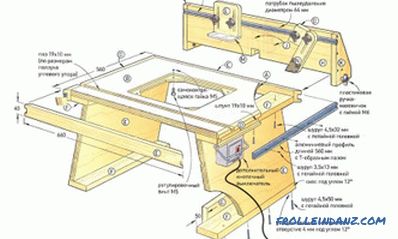

Scheme of thermal insulation of walls with sawdust.

In the process of insulation of the house or bath with sawdust, it is necessary to ensure their maximum hardening. For such purposes, it is necessary to mix the total mass with gypsum, its permissible amount will be 5% of the composition. When preparing such a mixture, it is necessary to remember that rapid solidification is peculiar to this substance, for this reason a large amount of the solution should not be diluted immediately. Gypsum may well be replaced by low-cost varieties of cement. The mixture with sawdust provides ease of operation and a sufficiently long drying period. Cement, having absorbed all the moisture from wood chips, will quickly harden.

Warming of sawdust is often associated with increased risk of ignition of the pediments of buildings. It arises because of the need to make room for wood chips, in connection with this gables carrying fire-fighting function, are removed. Their absence can cause strong cravings, which is dangerous, especially in the bath room, where any spark causes early ignition. Often, under the windows make removable window sills, which will help to easily pour sawdust as needed.

Wood chips as a heating element for the house and bath should be large, obtained in the process of wood processing on existing power-saw benches. Furniture production produces too small raw materials that are not suitable for the types of work under consideration.

The process of making sawdust mixtures

Thermal insulation of buildings with sawdust materials is associated with the preparation of appropriate mixtures. Each of them is associated with a specific recipe. However, their approximate composition is identical:

The binder solution is made from lime or cement mixed with water and antiseptic.

- For 10 buckets filled with sawdust, take 1 bucket of lime and mix thoroughly.

- To the mixture obtained, add 8-10 liters of water diluted with boric acid or copper sulfate. These substances are known for their excellent antiseptic characteristics, which is especially important for a bath. Fluid should be infused smoothly.

- The prepared solution is infused for 5-10 minutes, after which it can be used. The surface of the walls must be vapor proof. Asking will be a good basis, ruberoid is not recommended.

Dry prepared components should be thoroughly mixed, after which you can add water by pouring it in a thin stream from a watering can. The finished mixture is as follows: the composition is taken in hand and compressed, the resulting lump should be flexible and not fall apart, there should not be excess water.

The finished mixture of sawdust is placed in neat layers, which are small in size, only 25-30 cm.

Measured styling should be combined with good tamping. Then other layers fit, and so on until the entire base is filled. In some cases, used diluted composition of sawdust and lime. Its cost will be slightly higher, but the moisture level will be lower. The mixture will not settle too hard, which is very valuable for placing the bath, which means that it will not be necessary to carry out periodic pouring of the material. It should be noted that any work with wood chips is associated with a high degree of dustiness; the process of cooking and pouring the base with the mixture will also be difficult.

Materials for high-quality thermal insulation of walls

These are:

- sawdust;

- cement mortar;

- antiseptic (manganese, boric acid);

- lime;

- capacity;

- shovel;

- watering can.

The main stages of work

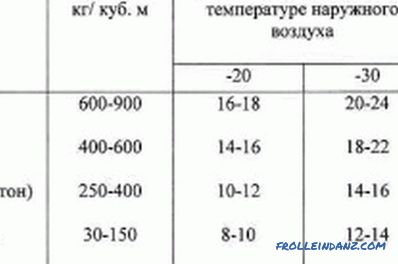

Table of characteristics of materials for wall insulation.

To ensure good thermal insulation of walls in country houses and hozblokah (bath) actively used sawdust, diluted with lime. This substance acts as an excellent antiseptic and a means unattractive to rodents. The prepared composition is poured onto the waterproofing layer little by little, after which it rolls well. The result is an excellent community with high-quality thermal insulation.

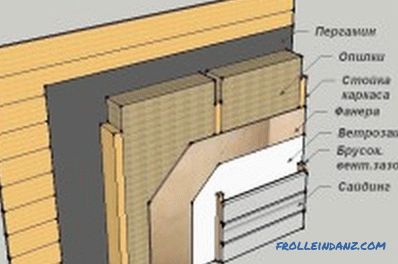

Warming of the walls with sawdust is associated with their plywood or clapboard trim. Asphalt is laid under them. Outside, the floor is made of edged board or moisture-resistant plywood. After this, a ventilation system is installed. It is done as follows: a bar with a section of 40 * 40 mm is taken, which helps to build an appropriate gap. Wall insulation from the outside is completed with siding or a block house.

The process of finishing the partitions of a house and a bath with selected raw materials should be regulated by a certain wall thickness, which must be 15-17 cm. The thickness of the ceiling is 25 cm. As a result of this insulation, in any season a pleasant and healthy microclimate will be maintained in the room.

The size of the area of such buildings is 35-40 square meters. Heating the oven 2 times a day will help maintain a stable temperature in the room. With permanent residence in a building, wall insulation should be slightly increased, changing their thickness. To do this, it is necessary to install an additional base from the boards; it is also important to fill this layer with a “warm” composition. Such a building is not afraid of the most severe frosts.

Thermal insulation of walls with sawdust should be inextricably linked with strict adherence to fire and electrical safety standards. The points of the chimney are equipped with special separation spaces, which are covered with non-combustible materials. Electrical wiring should be located on the outside, then as a result of the closure, the layer of insulation can not catch fire. It is placed in metal cases in the form of tubes, their thickness should be more than 3 mm. The room in which the main work takes place should be thoroughly aired.

Additional points

Wall insulation can be carried out using a ready-made “warm” mixture. For this purpose, a frame is made into which wood chips are poured. Wooden strips are fixed on the wall with observance of equal distance, the crate is fastened on them. The warming layer can have different heights, which is determined by the climatic features of the area and the functions of the building. So, for heating a country house intended for summer holidays, a layer of walls of 15 cm will be sufficient, while the dwelling should have a thickness of 30 cm.

After 14 days drying of sawdust, you must check the finished base for voids. When they are detected, the surface is again filled with the mixture. Sawdust are actively used as insulation for the walls of country houses, baths, outbuildings. In the course of the work should take into account some features. The stated rules will help to increase the life of the building and will help to maintain heat in the cold period.

Didn't find the answer in the article? More information on the topic:

-

The better to process the wood from moisture

How to process wood from moisture. Useful tips and tricks, basic characteristics of impregnations and materials, design features, nuances. Advantages and disadvantages of impregnation.

-

How to caulk a blockhouse?

Instructions on how to caulk a log house with your own hands. Practical recommendations necessary for work tools. Caulk of different materials. Useful tips.