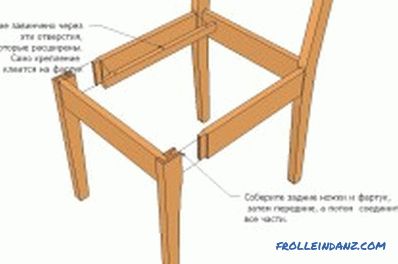

The process of making chairs with your own hands involves the preparation of a drawing. This will require graph paper and a pencil. Chairs for the kitchen are made using planer, chisels, saws, glue, stapler, screws, plywood.

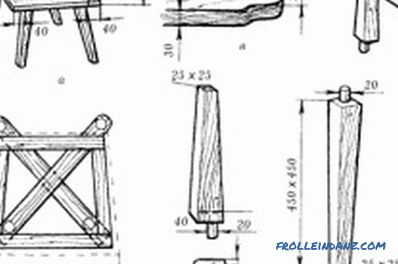

Drawing of a wooden chair.

Main production steps

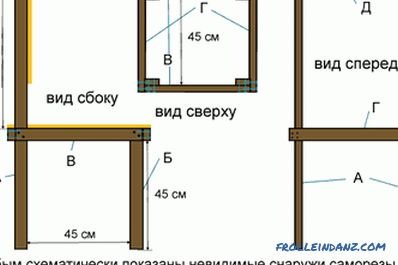

To make the model in question, you need a planed dry board, the parameters of which are 10x2.5 cm. Saw 2 rails of 55, 65 and 50 cm and 1 board length 40 cm. In the places where the screws will be installed, make holes. Their diameter must match the diameter of the threaded fasteners. Under the cap make a recess.

Joints of the blanks are treated with glue. If the composition is dry, then put the parts in place, tightening them with screws. Last fasteners must securely glue the parts together. Boards are connected according to the scheme of the chair. The parameters of the backrest are 45x45 cm, and the seats are 70x50 cm. Under the backrest rack you will need to prepare a cutout of 12.5x5 cm. .

Self-assembly scheme of the kitchen chair.

If desired, structures give a figured appearance. The surface is sanded. The seat and blades are fixed to the frame of the chair with screws. For the back you will need 9 fasteners, and for the seat - 12 self-tapping screws. Recessed heads stuffed. Chairs for the kitchen process mill and sand. It is recommended to paint the stool with enamel. This composition will protect the furniture from moisture.

The back is made using a chipboard 80-100 mm wide. Inside, you need to measure 40 mm to determine the width of the legs. The resulting elements are varnished and polished. Pre-material is fixed with a stapler. Then stack foam rubber. If the parts are dry, then the kitchen chairs are assembled. Each spike is coated with glue and wrapped around the material. The back is fixed with screws. If the glue is dry, then the chair is ready for use.

Other modifications

For the manufacture of the stool will need a tree. From a constructive point of view, such furniture consists of 4 legs, tsarg, crackers and seat. The last element is made of 5-7 boards, whose width is 60-80 mm and length - 385 mm. Dimensions of crackers are within 70x70 mm. Holes are made in holes in diameter of 25x30 mm. The parts obtained are fixed to the seat with nails and glue. For the manufacture of legs using various shapes, including a circle and a square. The main thing is that the neck size goes into the grooves provided for in the king-pieces.

To ensure durability, it is recommended to fix the legs in the last elements using wood glue.

Diagram of a chair with a cruciform armor.

Saw spikes on the ends of the legs. For the manufacture of such furniture used coniferous wood, the humidity of which should vary between 2-8%. The legs are made of timber with a section of 45x45 mm (length 460 mm). Details of the stool need to be assembled without gaps. Pre-assembly of the chair is made dry, then - with glue.

To make folding chairs for the kitchen, you will need the following materials:

- timber with a cross section of 3x3 cm;

- 2 cm thick boards;

- steel bar with a cross section of 1 cm;

- fasteners;

- PVA glue.

Pre planks are laid out (with the polished side down) in 1 cm steps. The bars are placed on top. Marker mark the position of the material. The design is turned over and screws attached to the uneven bars. In the last elements make a hole through which thread the rod. For bolts prepare a similar hole (at the level of another board).

To fix the long legs, you need to make holes on the outside. The diameter of the head of the bolts is taken into account. From the inside make a slot. In the upper part provides a hole for dowels.

At the same time, the rod is clamped and the transverse ligament is fixed. The parameters of the last design are 34 cm. Holes are made at its ends. For fixing the transverse ligament use screws in 40 cm. The legs are connected to the seat.

Didn't find the answer in the article? More information on the topic:

-

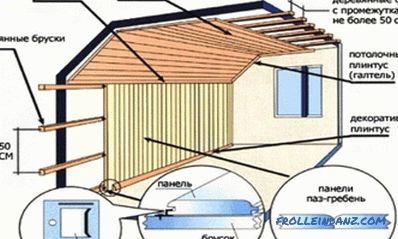

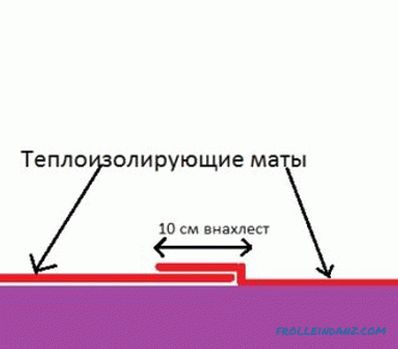

Skeleton country house: do-it-yourself installation

You can build a frame country house with your own hands over the summer. Frame construction involves the use of fairly lightweight materials: wooden bars, OSB sheets, insulating mats.

-

How are wood veneers made?

Information on how to make veneer. Three ways of industrial manufacture of veneer. Making veneer your own hands. Finishing veneer of various surfaces.

-

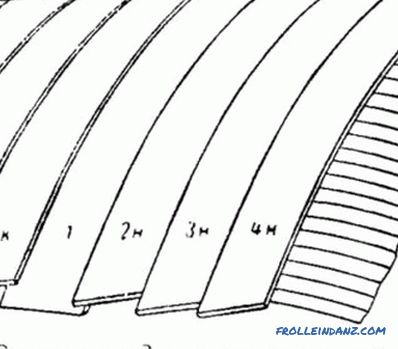

How to make flooring in a

You can make wooden floors as well as other materials for this. If bricks were used to organize the foundation, the beams are placed immediately behind the basement floor.