A tree, like any of the materials, has significant differences. They relate to the appearance of the rock and the quality of surface treatment. What is lumber? This is a fairly extensive term, which is represented by a set of numerous product names. These include all materials for construction purposes, as well as elements that are used as base cladding. They are made from natural wood using mechanical grinding of the surface. Materials of this category are used in many construction industries.

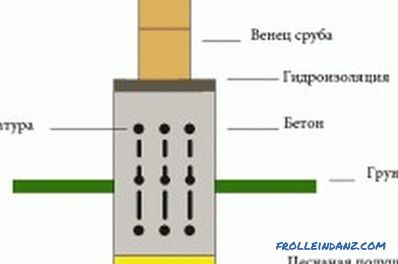

Wood structure defects: a - fiber tilt; b - heel; in - crookedness; d - curl; d - eyes; e is a false core.

Speaking about the quality of wood, it is important to take into account the effectiveness of its sawing. What are the indicators estimated timber? Calibration of wood is carried out according to external indicators of the breed. In order to conduct a visual assessment of the material, it is necessary to divide the proposed formation mentally into 4 parts. Any face should not have such visible defects as branches, cracks, scars, rotten areas and other mechanical damage. The importance of wood consists of the external purity of its base. Focusing on the grade of lumber, you can choose for yourself the most successful version of the boards, featuring good quality and decent exterior finish.

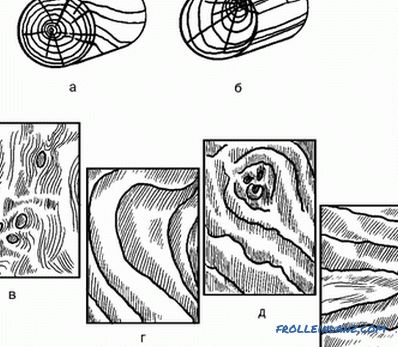

Wood cutting options.

While giving preference to one or another type of wood, it is important to clearly know the purpose for which the material is chosen. Is it necessary as a construction element or will they be facing the room? Here it is necessary to take into account the proposed specifics of the purpose of the material.

Having picked up boards for the above mentioned indicators, it is necessary to pay attention to the species and the type of tree. Such signs characterize the material. Important indicators of the quality of wood will be the degree of moisture, the strength of the base, the presence of a flat surface, the absence of knots and other defects. Before you make an order for the manufacture of boards with certain data, you should find out the desired size.

Speaking about the parameters of lumber, it is necessary to recognize their diversity. Making a choice in favor of one or another option is not easy.

It is known that wood of the first grade will be the best material. It is used in the construction of ships and aircraft. You can find out whether a material belongs to a certain grade using various methods.

How is wood calibrated?

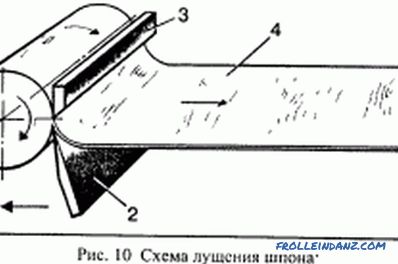

The veneer peeling scheme.

To set the type of tree, you can use the following method: take a whip and divide it into parts. The first one is called the middle one, the second one is the butt one, the third one is the top one. It is worth noting that the best results are provided by a domestic species of tree species.

The fact is that these sawn timber on the side parts have no knots. The presence of a significant number of defects can be observed on the median variety of material. To determine the varietal affiliation of logs, it must be remembered that they are divided according to their characteristics into 4 grades.

How are different sorts of materials used?

Most species are valued for specific purposes. They belong to the 1st grade. Such bases are excellent for the production of high-quality veneer.

For lumber of 2 grades, it is typical to use them in the construction of exchanges, machines.

The sleepers for railways and conversion bars are made from wood belonging to the latter category. Similar material 3 grades are used in furniture production. Tara and similar products are made of low quality wood. These types of boards have a low price.

Determination of wood grade

Types of sawn timber.

Taking into account the differences in the external characteristics of the tree, it is important to be able to properly divide them into the appropriate categories, which are called "varieties". Here it is important to focus on certain data:

- The uniformity of the base.

- Persistence.

- Presence of visible vices.

- Sizing of visible defects.

When conducting a similar analysis of rock coverage, it is important to focus on the sides with the largest deviations. Once a full inspection has been made, you can affix the appropriate marking to the lumber that is suitable for it.

Differences between different types of wood

Types of lumber and laminated wood.

Taking into account the grade of materials, it is important to distinguish them by the following indicators:

- The lumber of the selected varieties are selected for the species with the smallest number of flaws, cracks and knots. There are no putrid and fungal lesions on them. Disadvantages of a natural focus on them are not found, and if they are present, then in small numbers.

- As lumber of first grade wood is represented with a small number of knots and crevices. Often this kind of material is used in construction, and the main parts of any devices are made from it.

- For sawn timber of the 2nd grade there is a soft base and a slight presence of flaws. In construction areas such boards are used as the basis for the construction of supporting structures.

- The third grade of sawn timbers is used in floorings and skins that are not subject to strong pressure. Bases of this type may have a wavy surface or breaks. Here, occasionally you can see small defects in the form of fungal or putrid lesions. There are also flaws of a natural character.

- The last, fourth type of tree reveals a significant number of various irregularities in appearance. For material of this type it is important to maintain the integrity of the base. Wood of the above category is used as an element of a variety of blanks, carrying out a minor purpose.

Establishing the nature of the timber moisture content

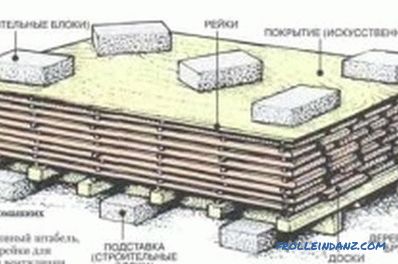

Drying wood at home.

During construction work it is necessary not only to find out the grade of the named materials, but also an indicator of their humidity. This level must be defined as a percentage. To do this, you can apply several options.

To correctly clarify the level of humidity and to obtain more accurate results, use a special purpose device called an electro-moisture meter. The rules of his work are as follows: a metal needle is inserted into the tree, then the current is turned on. It passes through the wires, which are securely connected to this needle. Such a measurement can be carried out in different parts of the material, whereby more detailed information can be obtained.

In the absence of such a device, it is necessary to verify these readings, guided by their own observations. To do this, you can use the plane, which are cleaned the upper chips. Then they are compressed in the brush.

By the quick breakage of footage, you can judge the low level of humidity.

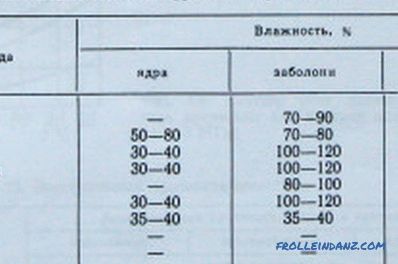

Table of humidity of freshly cut wood.

Wood with such indicators is suitable for storage and construction.

If, during the compression, the chips easily wrinkle and there are no creases on it, therefore, the material must be dried beforehand. But this should also comply with the measure, because too dried boards will not bring good results. They will quickly crack and crumble. In addition, blanks of this type do not allow the screws to be screwed into them, which is associated with their quick breakage.

To independently determine the moisture content of boards, it is necessary to have experience and skills in working with wood. This knowledge will help determine with certainty the density of the rock and the degree of fullness of its moisture.

When evaluating such indicators, it is important to be extremely attentive, because often from inappropriate values the material loses its initial indicators and quickly collapses.

From all this, it should be concluded that these products are best purchased from well-known manufacturers, who attach great importance to the quality of materials and store the goods in suitable conditions. They strictly observe the temperature regime and general storage rules. On the other hand, suppliers do not think about such rules.

Therefore, choosing the appropriate material, you should be very careful. Taking into account the distribution of wood by grade, you can significantly save your own costs. Despite the obvious reduction in the number of forests, finding a suitable option is not difficult.

Didn't find the answer in the article? More information on the topic:

-

What types of lumber exist?

Types of sawn timber: according to the method of processing raw materials, sawn timber is divided into unedged and edged. Depending on the processing method, the materials may be called unmilled or milled.