Glulam is one of the widely used materials used for the construction of country houses. This is due to its low shrinkage, which allows you to immediately settle in this building. In this regard, the construction of houses from glued laminated timber has been widely used recently.

Advantages of laminated veneer lumber.

Choosing a place for construction

For building a house from glued lumber, you need to use high-quality, well-prepared material, the laying of which is better to be entrusted to professionals. Otherwise, even from such magnificent construction blanks, like glued laminated timber, you will end up with a house unsuitable for living.

The process of building houses from laminated veneer lumber is carried out in several stages, which must be carried out strictly according to the construction technology.

Construction of the wall of glue bar.

Violation of at least one of them will lead to the impossibility of operating the entire structure of the building. Therefore, strict adherence to the technological order of assembly is the key to success in future construction. In this case, an important factor is both the planning of the building structure and the subsequent maintenance of the erected structure.

Before you start building a house of laminated veneer lumber, you need to conduct a good geological survey. This will help determine the possibility of whether to apply glued laminated timber as a building material. In the event that the soil will have a low coefficient of bearing capacity, the construction of a house of such material will be simply impossible to carry out.

Selection of the required material

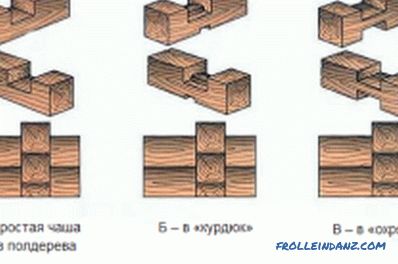

End connections of the bars.

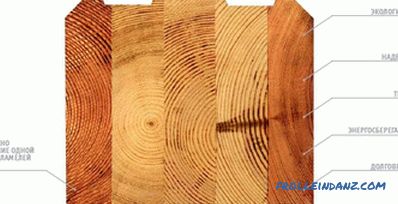

After the place with the necessary ground has been chosen, you need to proceed to the purchase of laminated veneer lumber. In the event that it will be purchased on its own, you should pay attention to the quality of drying wood. Blanks for the house of glued timber should be well dried and made of wood harvested in the winter. This will help to avoid further deformation of the bars.

Moreover, on the surface of the beam there should not be various knots and all kinds of cracks. Also should not be present areas with remnants of the bark. When checking glued laminated timber, it is necessary to pay close attention to the quality of the glue used. The adhesive composition must be such that the separation of different sections of the beam is not allowed. This separation will lead to further deformation of the part, and then the whole structure of the walls of the structure.

A well-glued timber should not be inferior in its strength characteristics to solid pieces of wood. If lamination and deformations are observed, therefore the manufacturer saved on glue. The first signal for the refusal to purchase such a laminated timber can be its unreasonably low price. The value of the discount can not be higher than 10-15%.

Delivery and storage of material

Layout of a laminated timber house.

After purchasing the required amount of material for the construction of a house of glued laminated timber, it is necessary to make its delivery to the desired place. It must be transported properly. To do this, such a building material must be processed using special transport antiseptics. The ends of the bars must be processed by means of moisture insulation.

After the material is delivered, it must be properly laid. Do not allow the unloading of building blanks heap. The material for the house of laminated veneer lumber should be stored in neatly stacked piles under a specially equipped canopy. This will help to avoid moisture on its surface.

At the same time, various sags and bends of the bars should be avoided, and the material should not be allowed to touch the ground. To do this, the bottom row of blanks should be placed on special pads. The same lining is required to lay between all rows of blanks. This will help prevent stagnation of moisture between them and the appearance of fungi and mold. Proper storage of timber blanks is the key to successful construction.

Construction of the house

During the execution of the construction work, close attention should be paid to the following points:

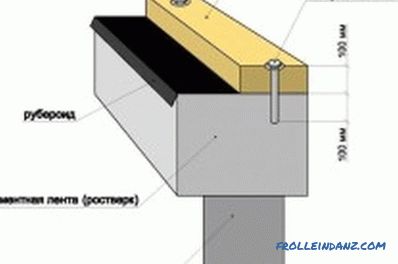

- to prepare the trim of the foundation;

- to manufacture the basement part of the foundation;

- row laying density.

Bar fastening scheme.

It is necessary to conduct waterproofing on the trimmed part of the foundation before laying the first row, which serves as a trim. For these purposes, it is better to use rolled insulation materials, on top of which you should lay a backing board. It must be pre-treated with antiseptic formulations.

The basement of the foundation should be made high. This is conceived so that the amount of snow cover does not reach the strapping crowns.This will help prevent premature damage to the wood.

During the assembly of crowns at home, you must use a dressing. This procedure will prevent the occurrence of various cracks and large gaps between the rows of wood. The presence of such deficiencies is simply unacceptable, since water and various natural sediments will fall between them. Moreover, it will be very difficult to keep warm in such a house. With the appearance of gaps and various indentations, it will be necessary to close them with tow. The use of foam in this case is simply unacceptable.

The final stage of work

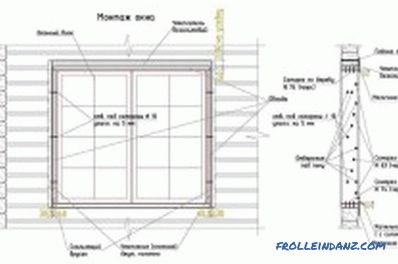

After assembling the entire structure of the house, you can proceed to the installation of windows. During installation of window structures, as well as various doors, it is mandatory to use casing boxes.

For a building to be stable, it is impossible to allow devices that are not taken into account in the project of door and window openings. All such elements should be provided at the design stage.

After the installation of windows and doors, it is necessary to proceed to the treatment of all wood using antiseptics. Such work should be done during the first 3-4 months after completion of construction. The use of such measures is simply necessary because it will help prevent the darkening of the wood surface and the appearance of various fungi and mold on it. The emergence of organic growths significantly reduce the performance of the material. Such a protective composition should be applied in 2-3 layers, but only after the previous one has dried.

Building a house from glued laminated timber is a fairly important undertaking. If you are not sure that you can cope with it yourself, it is better to entrust the implementation of this business to professionals who will not only produce all the quality work, but also select good material for construction.

Didn't find the answer in the article? More information on the topic:

-

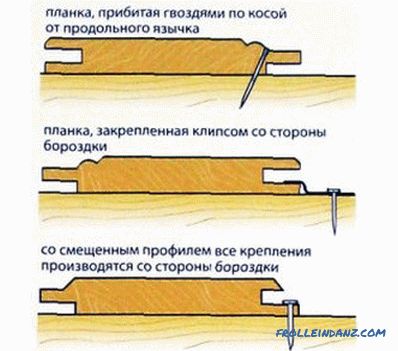

Mounting steps for wooden lining

Installation of wooden wall paneling consists of several stages. You can fix the boards in several ways: nail, use clamps, use a construction stapler, attach with screws.