Why is laying solid wood on a screed or other foundation considered not only the most aesthetic, but also the most reliable way?

Boards of solid wood are eco-friendly, durable and durable material.

Solid wood planks are eco-friendly material, there are no chemical additives in it. Throughout its operation, wood releases useful phytoncides into the atmosphere of the room, which help to purify the air and create a unique aroma. Unlike laminate and other synthetic coatings, natural wood does not electrify, does not attract dust. The natural material perfectly transfers both chemical, and mechanical influences, it is simple in leaving and is unpretentious in operation. Solid wood board is characterized by very low thermal conductivity and excellent noise absorbing properties.

Another, more important, advantage of a massive board is its strength and durability. A floor from an array with good care can be operated by more than one generation. But for this to happen, the laying of solid wood must be done according to the rules.

Methods of laying flooring from an array of

Laying a plank of solid wood on an old wooden floor.

Boards are a convenient and practical, easy-to-use material. You can lay them in different ways. Each of them implies its own algorithm of work, has its own minuses and positive aspects.

- You can lay the boards on the screed. The least expensive way, since it does not require the purchase of additional materials (except glue) and great effort. It is carried out only on dry (less than 6% moisture) masonry, which should be perfectly flat. If the screed has chipped, height drops or other defects, it will have to be updated. Is the humidity above normal? Will require additional waterproofing. If the glue, which is used for work, is resistant to temperature fluctuations, then a solid floor can be equipped with a warm floor.

- Installation of boards on logs. Most often it is not used in the reconstruction of the floor, especially if the use of cement mixtures is impossible for any reason. On the logs you can equip the podiums. This method of installation implies mandatory waterproofing. It is also advisable to fill the space between the lags with insulation. At first, the plywood base is fastened to the logs, and the boards are already laid on top of the array.

- Increasingly, laying of solid wood is carried out without fastening to the base, in a “floating” way. Usually for this purpose two types of flooring are used. If the tongue and groove system is not equipped with special self-locking locks, then glue or staples are used for fixing the boards, which are placed in the grooves. They securely fix the coating, while remaining completely invisible. If the boards are equipped with locks according to the "block-button" system, then during installation they simply snap into place at the end.

- Laying solid wood can be done on the old floor. However, this method requires preliminary preparation of the base. At first it is strengthened, tested for strength and the absence of creaking, damaged dies. Then paint and varnish are carefully removed from the old floor, and its surface is polished. After removing the dust, a new coating of solid wood is laid. It should be laid in the same direction as the old floor.

Today, many people prefer to “sew” massive boards on plywood. How to do it correctly?

How to mount a massive board on plywood correctly?

Laying a massive board on a plywood floor.

A few days before laying the board, it is recommended to unpack it, bring it into the room where they will be laid, leave it (preferably on a stand). The material must "acclimatize". Shifting the boards, you need to immediately sort them by color, remove low-quality products.

It is possible to lay solid wood floor only on a perfectly prepared base. It should be:

- Structurally complete, even, without defects.

- Well cleaned from dust, debris, remnants of the previous coating, glue, sealant and all the other things that interfere with high-quality styling of the finishing coating.

The installation of a massive board on plywood is carried out according to the following algorithm.

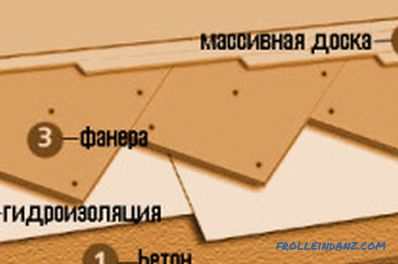

The plywood is fastened directly to the concrete screed. In this case, the coupler must be flat, smooth, without chipping, protrusions, height differences.

Figure 1. Sheets of plywood are shifted relative to each other so that the four corners do not converge in one place.

The humidity of the concrete should not be more than 12% and less than 4%. If necessary, a humidifier or air dryer can be used in the room.

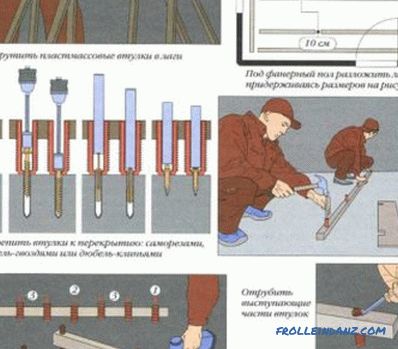

If these indicators cannot be reached, then first waterproofing is applied to the screed, and then plywood sheets are placed on top of it. Plywood is attached to the screed with dowels, and so that their caps are recessed.Sheets are shifted relative to each other so that in one place the four corners do not converge (Fig. 1). Each sheet of plywood should be secured in at least nine places. An alternative way to fasten plywood on the screed is to glue it.

If the work is done correctly, the plywood forms a completely flat base.

If minor defects are still present (for example, chips at the joints), they can be repaired with a sandpaper or grinder.

The plywood base should be smooth and even. It should be cleaned from the remnants of debris and dust, and then mount the board on plywood.

How to lay a massive plank correctly?

Figure 2. The rows between massive planks can be fixed with glue or staples placed in the groove.

With a careful approach to the work, there is no particular difficulty laying. It is only important to observe certain subtleties so that the floors do not "swell" during operation and begin to creak.

- There should be a gap of 1-2 cm between the wall and the nearest plank (or board) to it. It is necessary for the boards, which change sizes under the influence of humidity and temperature, to move freely.

- The first line is mounted by turning the boards with a groove to the wall. Since the baseboard will lie between the wall and the floor, they can be fixed directly on the front side.

- All subsequent rows can be fastened with glue or staples placed in the groove (fig. 2). If the mount goes on the front side, the cap should be closed with special traffic jams. This method is less aesthetic, although it takes less time.

Sometimes the last board in a row has to be cut to make it shorter. To do this, it is better to choose the longest bar so that one part of it becomes the last in the same row, and the other part becomes the first in the next.

You can stack an array directly on the tie, but only if it is a perfectly level base.

Didn't find the answer in the article? More information on the topic:

-

How to level the floor in a new building with your own hands?

Instructions on how to level the floor in a new building with serious drops in the horizontal surface of the base. Preparation and leveling of floors using log or cement-sand screed.