Wood floors have never gone out of fashion. But if earlier they were popular in houses and apartments only due to the absence of other similar materials, today, real wood floors are chosen by those who prefer to live in an environmentally friendly or cozy home. In the article we will look at how to paint such a coating in a house in the country, in an apartment, on a balcony, and also in a garage.

Choice of paint coating

Choice of coating

Choice of coating

A variety of paint coatings designed for Wood floor processing is simply amazing. In this situation, no wonder and get confused. When choosing a paintwork material, consider the following:

- Wood species.

- Operating conditions. This includes the level of humidity, temperature, whether there is heating.

- Compatibility with the previous flooring (in the case of old floors).

All paint coatings designed for wood coatings are conventionally divided into transparent and opaque. If we talk about transparent formulations, they can be divided into 3 types:

- Lucky.

- Oils.

- Waxes.

Varnishing

Varnish is essentially dissolved natural hard resin, nowadays it is also synthetic polymers. Depending on the solvent, lacquers are divided into several types:

- water;

- turpentine;

- alcohol;

- oil;

- polyurethane;

- urethanized;

- polyurethane-acrylate.

There are cases when floor varnishing is unacceptable:

- The old coating was previously treated with linseed oil or other oil formulations.

- Outdoor playgrounds - terraces, gazebos, verandas.

- In rooms with high humidity levels.

The varnish penetrates no more than 2 mm into the pores of the wood, forming a film outside. Therefore, if in the future you want to change the coating, then the old lacquer can be removed with a scrub.

Painting

The floor is covered with an opaque paint in order to protect the wood from mechanical impacts and if the quality of the wood is not presentable to maintain its natural structure.

If you have to paint in a room with high humidity, then use a waterproof acrylic paint for this purpose.

Worried about paint safety for health? In this case, you are suitable water-dispersion paint. Its advantages are long-lasting color retention and ease of application to a wooden surface.

The main advantage of painting the floor is that it can be repainted if necessary several times.

Oil coating

The most ancient method of covering a wooden floor is to oil it. This is an environmentally safe method. For these purposes, use sunflower, soybean, wood, linseed oil. As well as natural modified resins and synthetic polymers.

The oil penetrates deeply into the wood structure, exerting a preservative effect on the material, which serves as protection for the coating against the effects of pathogenic flora and internal changes.

The oiled floor will not swell or dry out. You have the opportunity to choose the oil that does not affect the color of the tree. There are oils that change color from whitish to red-yellow, brown and black.

When wood is impregnated with natural finishing oil, it needs to be opened with wax.

The wax coating

When making wax, linseed oil, beeswax and other additives are used to cover the wooden floor. Waxed wood has a golden hue and flickers with silky light.

This coating has high moisture resistance, but is not protected from mechanical impact. In view of this, it is unprofitable to use a wax coating in rooms with high traffic.

It is interesting that in the past, polisers served in the royal palaces, whose task was to rub the wax floor with a special tool every day.

Old floors

Old wooden floors

Old wooden floors

If you have kept your room old wooden floors, then, most likely, they have already been painted several times. And therefore, you should focus on the following points:

-

Coverage of the old wooden floor existing color (to paint a dark shade more light, you may need more 2 coats of paint);

Coverage of the old wooden floor existing color (to paint a dark shade more light, you may need more 2 coats of paint); - a type of previously used paint (if you can’t remember what you painted the previous time, rummage around in your “stocks” of materials on the balcony or storeroom, because, as practice shows, the jar of paint is often not thrown away, and there is always a little paint left in it;

- its financial capabilities and the availability of a suitable color ki in the store.

As an option, you can try to completely remove the old paint, ottsiklevat floors and varnish them. However, if the boards during the time of their "service" led (they became either "humped" or, conversely, concave), no master could take up the chiseling.

There will be a problem with the presence of nails hammered into the boards on top and hiding under a layer of old paint (this is how the floors in public buildings, for example, in schools, are usually “repaired”). In such cases, it is better to think about the complete replacement of the old wooden floor with a more modern flooring.

But the parquet (it is almost all of oak), even the old one, is much easier to ottsiklevat. It remains only then to cover the surface in two layers with varnish (with or without a shade) on the primer.

Video

All complex of parquet repair works:

New

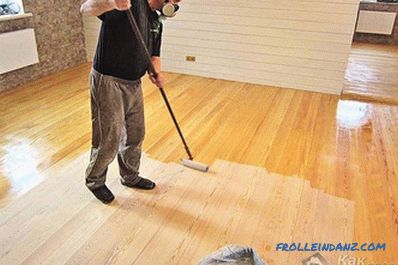

Protective layer varnish

Protective layer varnish

New wooden floors, which have never been painted, leave more room for choice.

If you want to preserve the color and texture of wood, then prefer colorless varnishes with good wear resistance. If the natural color of the boards or parquet planks differs in color (in some places of the surface), it is better to use a tinted varnish that will hide this not very pleasant nuance.

Video

When choosing the best way to paint the wooden floor of a country house, be sure to find out what wood it is made of. The fact is that some breeds of trees have soft wood (for example, pine), on which even a thin female heel can easily leave a dent. Therefore, to cover it is necessary to choose a special varnish (for soft wood or strictly for a particular tree species). A simple parquet lacquer will not work in this case, since it is designed for durable and tough wood (mainly oak).

The methods of applying lacquer also differ:

- parquet lacquer is applied with an obligatory preliminary priming of the surface (get the primer immediately in the store, and it is desirable that it be of the same manufacturing company that and your chosen varnish);

- the varnish for the floorboard is simply applied in three layers, each of which must be completely dry.

Toning a wooden floor

Toning a wooden floor

If, according to a design plan, your floor should have a certain shade, You can choose one of two ways:

- pre-toned wood with special stains in a suitable color, and then apply a lacquer coating on top (in two or three layers),

- immediately use colored oils and waxing for wood (of course, after careful polishing), causing it manually or mechanically.

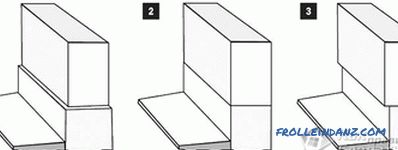

Elimination of deficiencies in the coating

Elimination of the gaps between the floor boards

Elimination of the gaps between the floor boards

Unfortunately, boards are not always perfectly smooth and without gaps. Therefore, before you go to the store and choose how to paint a wooden floor, you should think about how to eliminate the identified shortcomings:

- gaps between the boards can be puttied with oil putty, adding a little sawdust;

- irregularities and dents on the boards will first have to be puttied (with oil putty to match the paint, which you are going to paint) on the layer of dried primer or drying oil - in this case the floor is not varnished, but only wood paint is applied.

White floor

White wooden floor

White wooden floor

Looks very original wooden white floor. To obtain such a result, you need to:

- carefully polish the new coating, which has not been covered with varnish or paint before;

- if defects (dents) have appeared, putty them with a special putty (in When buying a store, specify whether it is tinted with colored oil with wax, or buy white putty right away;

- cover the surface with white oil with hard wax (use a brush to do this, after carefully mixing the composition in the can);

Coating the board with white oil

Coating the board with white oil

- minutes black 15-20 soft rags (cloth) remove not absorbed in the wood composition;

- a day later, apply a second layer of white oil with hard wax in the same way.

Unusual painting of the wooden floor in the country

Often the floors in the country do not differ in presentability. In view of this, it is customary to paint them, and not to varnish. But not everyone likes the usual painting in any shade of brown. How to be in this situation? We suggest you paint a pattern:

- Draw a scale template on paper. Then determine the size and color of the picture. To keep the borders of straight lines neat, use masking tape.

- Paint the wood floor with the base paint color.

- After the base is dry, apply the base color of the stencil.

- Then draw the details of the image.

Paint for floor painting

Paint for floor painting

For this job you will need:

- Paint.

- Templates.

- Ruler.

If you walk over the pattern with a brush with light / dark paint, the surface will appear more voluminous.

Sequence of actions

Sequence of actions

In this way, you can divide the space into functional zones. In addition, this idea may be practical in a narrow corridor. Painted coating, for example, in the form of a track looks very original. In addition, the painting may well be light. There is no need to clean the mat drawn on the floor, which can also be attributed to the advantages of the coating. All you need is a bucket and a mop, and the “rug” will again shine like a new one. Agree, it is convenient.

If you are a supporter of varnished floors, then we suggest you to put a light, bright ornament on the varnished surface. In addition, with the help of paint you can make an imitation of expensive wood inlays.

Wooden flooring in the garage

The wooden floor in the garage is a solid foundation that does not produce dust in the room, unlike its concrete counterpart. However, such a coating will not be resistant to abrasion and mechanical stress, if it is not pre-treated. Also, as you know, wood quickly absorbs odors, and even more so in the garage.

For painting in, you should choose the compositions that would improve the wear resistance of the tree at times.

Polyurethane varnishes were specially developed to obtain a durable wooden flooring. They are 100% polyurethane in an organic solvent without asphyxiating alkyd additives. Types of coatings:

- glossy varnish for interior work;

- impregnation for interior work;

- glossy light-resistant varnish for outdoor work;

- light-resistant impregnation designed for indoor / outdoor use;

- impregnation and wear-resistant lacquer for light outdoor / indoor use.

The penetration depth of the impregnations is 3-7 mm. In comparison - the usual varnish has a penetration depth of up to 2 mm. After staining, a clear or colored film is formed. After curing, the finished coating is harmless to the human body.

Wooden floor in the garage

Wooden floor in the garage

These varnishes are used in temperate / cold climates. Can withstand temperatures from -50 to + 100ºС.

The paint coating is resistant to water, detergents, acids and aggressive salts in the temperature range -30 + 60ºС.

You can apply polyurethane varnish in the temperature range -15 + 40ºС. The surface must be dry, otherwise bubbles may form under the coating. Pre-treat the surface with toners, flame retardants and antiseptics. Only in this case, the coating will be durable. Also, before applying a polyurethane varnish, the floor should be sanded and dust should be removed from it. To make the coating matte, use polyurethane impregnation.

After the first layer of impregnation has been applied (approximate varnish consumption - 200 - 300 g / m 2 ), let it dry for 3-4 hours. Then remove the raised wooden pile. Use sandpaper for this purpose. Apply the next layer of impregnation at a rate of 150-200 g / m 2 . The varnish is applied in 1-2 layers, its consumption is 200-300 g / m 2 .

If you put in a little effort, turn on your imagination and enthusiastically do the painting in accordance with the recommendations outlined in the article, the result of your work will really be good. If you have experience in performing such works, then share it with us and our readers.