Country owners often plan to build a dwelling house on their own land. For construction, many choose wooden materials - it is both environmentally friendly and beautiful, and the works will not be particularly complex.

The wooden house is eco-friendly, beautiful, and most importantly, simple in construction.

The technology for building wooden houses is fairly simple, without the enormous amount of time and effort required. Even those builders who do not have much experience can put a house out of wood with their own hands in a short time. Of course, for this you will need to study some information, it is advisable to consult with more experienced craftsmen who can point out the nuances of this work and give advice on especially difficult moments.

Project of the future house

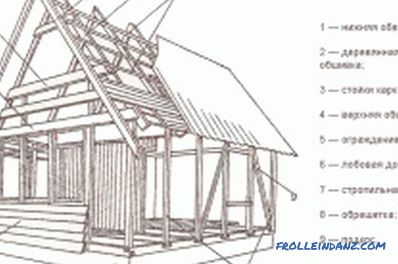

Scheme of a wooden house.

An important step will be the drafting of a residential house made of wood. To build a house with your own hands, calculations should be done as accurately and accurately as possible, since in the future this will seriously affect the amount you need to pay for materials.

You can draw the project yourself or contact the project company for help, where they will help you in drawing up a preliminary plan in strict accordance with the wishes of the customer. In construction companies, the compilation of the plan is carried out in compliance with all geometric rules. In this case, seismic resistance and other equally important factors will be taken into account.

Founding of a wooden house

Once the project has been prepared, you can start building the foundation. The technology of building a house of wooden building materials provides a foundation that is performed in accordance with all standards of reliability and durability. The stronger the foundation, the more durable the house.

It is necessary to choose the type of base depending on the following parameters:

- characteristics of the base of the soil;

- expected load value;

- features of a particular structure.

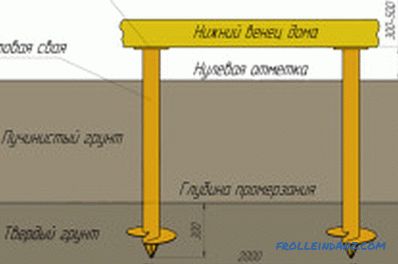

Screw pile foundation for a wooden house.

The base can be made of wood or concrete. Some developers choose a foundation of concrete. They lay a brick base on it, and then make walls from a bar. Others want the design to be completely made of wood.

There are the following types of foundation, which can be installed under a wooden house:

- band;

- deep;

- shallow;

- columnar.

A shallow-depth or ribbon foundation is usually laid at the base of the house from a bar. Prepare a platform for it. Remove everything that may interfere with work: grass and bushes, stumps, hummocks. When the site is cleared, it's time to move on to preparing the foundation pit. It must be dug in accordance with the dimensions specified in the project.

Soil that is removed during the preparation of the pit, remove away. Determine the depth of the base, depending on the type of soil and the depth of freezing. Pour the bottom of the prepared trench with a mixture of sand and rubble, after which everything is poured over with water and properly rammed. To enhance the strength of the foundation to perform it better with reinforcement. Concrete for pouring into the prepared formwork can be made independently or purchased in finished form.

After the concrete has been poured into the formwork, its surface must be periodically sprinkled with water so that it does not crack during the curing process. You can continue to work only when the concrete pick up the necessary strength. It is determined depending on the specific conditions: ambient temperature, materials used, and so on.

How to make walls and floor?

To build the frame of a wooden house you need only from dry boards without any defects.

After the foundation for the house is ready, start building a log house. Assembly technology should be chosen as closely as possible.

Before performing the bottom trim of the future structure, lay the roofing material in two layers on the base along the entire perimeter. Bars should be chosen carefully, they should be smooth, without rot and cracks. In the corners the pairing of the bars is better done using the thorn-groove connection.

Bars are joined together with the help of rectangular or round pins and nails of 200 mm. If crooked ones are caught among the bars, it is better to cut them and put them in openings, window or door. The selected material is placed on the base and fastened with staples.

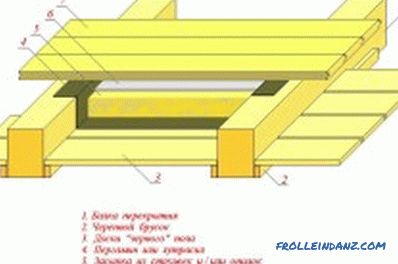

We proceed to laying out the genital lags. For them, the bars are stacked in 1 m increments. The ends of the lag can be installed directly on the base, if its width allows it. If not, inserts should be made into the strapping in which lags can be inserted. For large spans will need to arrange the posts. On logs, a temporary flooring of unedged boards is created.

Now you can start building walls. Place the tow on the lower crown in an even layer 1 cm thick. Lay the second crown on the tow, and continue, covering each row of bars with the tow. Each crown on a nail is attached to the bars of the overlying and underlying rims. Window blocks must be fixed to the wall every 3 crowns.

Floor insulation scheme in a wooden house.

In the logs, which are used for the construction of buildings, special grooves are made, due to which the individual elements are interconnected quite strongly. Untreated pine timber is used when they want to get a simplified version of the construction of the log house. It does not even require the use of special equipment, because the bar is very light. In order to work in the upper part of the structure, it will be necessary to make scaffolding.

Wood - the material is quite capricious, and it is desirable to process the walls of the building with special compositions to ensure fire resistance and strength.

The laying out of the walls can be completed when the distance from the floor to the ceiling exceeds 2.4 m. Check the last of the crowns diagonally and at elevations, fasten the corners with brackets.

Roof and floor construction

Roof materials can be chosen differently, depending on the chosen roof and roof systems. For different areas recommended the use of boards of different sizes. So, for racks, braces and rafters materials of different length and thickness will be required.

Roofing of a wooden house.

The roof overlap should be as secure as possible. It is made up of ceiling beams, laying them on the upper trim of the log house in increments of not more than 1 m. Irregularities are hewn with an ax. The beams are laid on the tow and are nailed with nails, between them are placed liners that protect from the cold space under the roof. Cover with overlapping unedged boards.

The roof will be assembled from rafters. Depending on the form that the owners have defined for it, the roofing material is also selected. It can be ondulin, metal tile, professional flooring. The form of the roof construction will also depend on the form, which includes installation of the rafters, waterproofing, thermal insulation, laying of the roofing material.

At last, the installation of interior partitions in the house is carried out, window frames and door frames are installed. At this stage, you can perform a rough flooring for the ceiling and floor, to carry out the laying of insulation, finish finishing. At the same time communications are laid.

At the stage of interior decoration, work is being carried out on setting and fixing window and door blocks. They are fixed using wedges in the openings and fastened to the walls of the house with nails. The slots are capped with tow, closed with casing. At the door unit threshold should not be above 7 cm from the floor.

The exterior finish of a wooden building is completely dependent on the wishes and capabilities of the owners.

Some developers like imitations of rustic style, i.e., raw walls. You can and so leave them, if the quality of the wood. You can paint the house or finish in any other way.

Didn't find the answer in the article? More information on the topic:

-

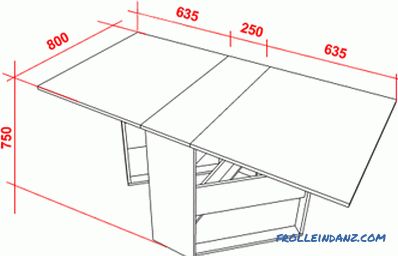

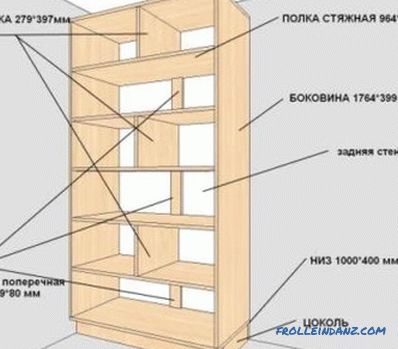

Properly making your own cabinet

Making a cabinet with your own hands is available to almost every person. It is enough to purchase the necessary materials and tools, and your product is ready for use. How to do it? Consider.